Melvyn Best

Member

- Messages

- 1,995

- Location

- Cambridge

Wouldn’t be surprised if the timing chain has stretched which has caused problems with the tensioner and guides?

Exactly what I was thinking. It does seem like you have just been retracing someone else's diagnostic efforts thus far.Given the loose bolts you found getting this far in, has someone recently found a deal breaker further in and just thrown it back together to get shot of it?

. and the crank pulley bolts were suspiciously easy to undo.

View attachment 199219[/QUOTE

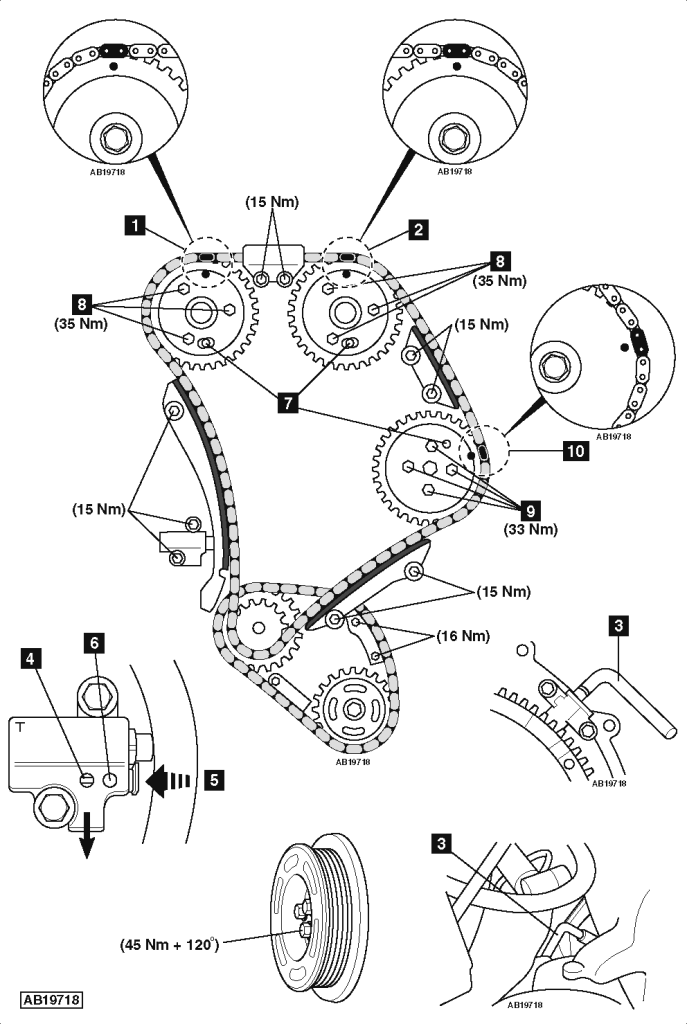

Could be a clue? Not sure if the crank sprocket is key to the crank ?

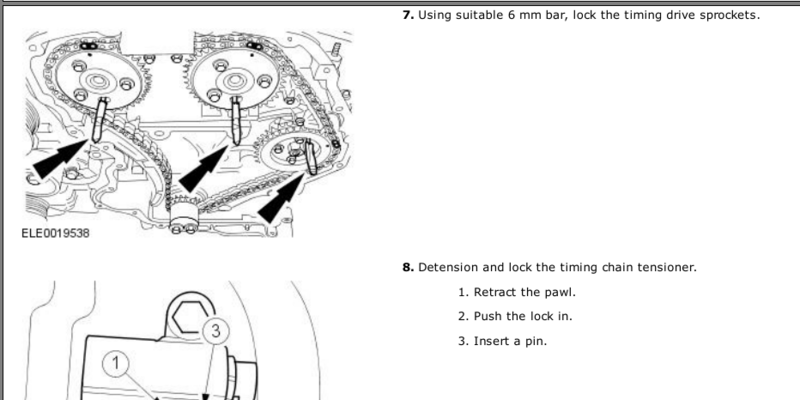

Thanks, got that in the manual, the issue is what the pin (3) goes into. I put in in the teeth gap as used by the crank sensor. Apparently not where it is supposed to go. No marks on the chain either annoyingly.