IIRC the timing has to be out 2 notches on the flywheel before the ECU will fail to synchronise, and it's more likely to cause a non-start, than issues once started.

The engine will likely be tighter to turn as the pistons go through the mid-stroke due to leverage angles.

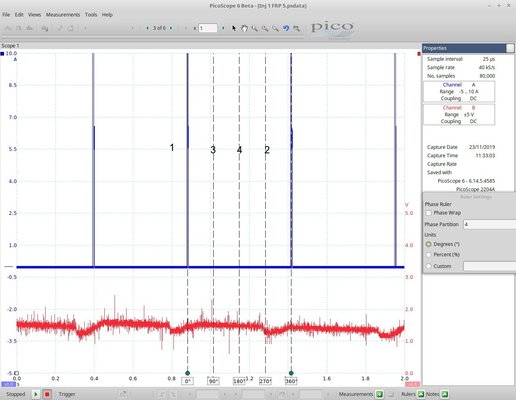

I wouldn't read too much into the scope traces. I'd be far more concerned about live data, to see what the ECU is seeing and attempting to do, rather than scope traces. For reference, this is the kind of thing I deal with on a regular basis, and I'm lucky if I dig the oscilloscope out it's box more than a couple times a year, and even then, the scope is just to prove what I already suspect. Which ironically, is normally issues surrounding crank sensors!

However, getting live data requires good diagnostic kit.

I'd be going back to basics, like is the engine drawing in air?

Is the ECU seeing the engine draw in air?

Is the inlet manifold pressure plausible (i.e. not showing a vacuum during cranking).

The fact you mentioned earlier the engine stopped with a bang, is the intercooler free from oil?

(which would show up in live data as a vacuum being formed in the inlet manifold during cranking)

It could be the turbo has failed, the engine's ran off on the oil, and would quite easily explain the compression/misfire issues (ran away engines can result in melted pistons), why it stopped with a bang (enough oil got sucked in to hydraulic lock the engine, but would drain out after being sat for a while), and why it now won't start (oil in the intercooler can be enough to stop air being drawn in, and as the ECU doesn't see air being drawn in, it doesn't inject fuel).

The engine will likely be tighter to turn as the pistons go through the mid-stroke due to leverage angles.

I wouldn't read too much into the scope traces. I'd be far more concerned about live data, to see what the ECU is seeing and attempting to do, rather than scope traces. For reference, this is the kind of thing I deal with on a regular basis, and I'm lucky if I dig the oscilloscope out it's box more than a couple times a year, and even then, the scope is just to prove what I already suspect. Which ironically, is normally issues surrounding crank sensors!

However, getting live data requires good diagnostic kit.

I'd be going back to basics, like is the engine drawing in air?

Is the ECU seeing the engine draw in air?

Is the inlet manifold pressure plausible (i.e. not showing a vacuum during cranking).

The fact you mentioned earlier the engine stopped with a bang, is the intercooler free from oil?

(which would show up in live data as a vacuum being formed in the inlet manifold during cranking)

It could be the turbo has failed, the engine's ran off on the oil, and would quite easily explain the compression/misfire issues (ran away engines can result in melted pistons), why it stopped with a bang (enough oil got sucked in to hydraulic lock the engine, but would drain out after being sat for a while), and why it now won't start (oil in the intercooler can be enough to stop air being drawn in, and as the ECU doesn't see air being drawn in, it doesn't inject fuel).