Melvyn Best

Member

- Messages

- 1,995

- Location

- Cambridge

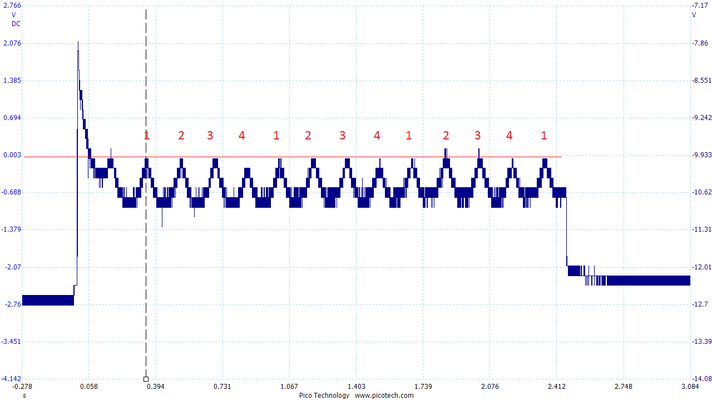

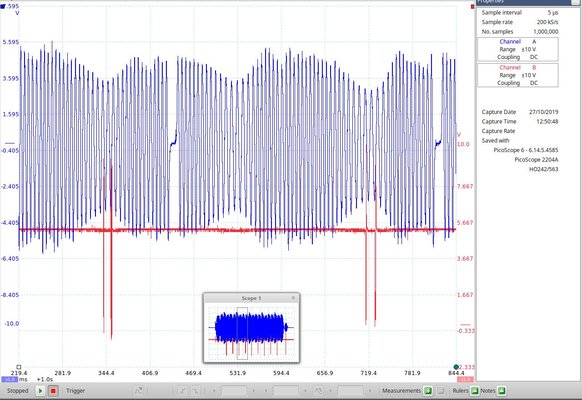

Have you checked to see if the injectors are actually being activated? You should be able to check using an oscilloscope, that would potentially eliminate the ECU,CPS and associated wiring?

- the fact it turned out to be more of a head scratcher than I thought is great! - CEL... but no codes and no start

- the fact it turned out to be more of a head scratcher than I thought is great! - CEL... but no codes and no start

This sort of thing is generally only stressful if its your only transport, or you have your life savings invested in it. This one looks like the mechanics equivalent of a good whodunnit novel. Have fun!Thanks @HopefullySoon but I think you missed that I am doing this for entertainment -I bought it as a puzzle to be solved!- the fact it turned out to be more of a head scratcher than I thought is great! - CEL... but no codes and no start

The thread has 3000+ views so it must be keeping someone else entertained too (that or y'all need to get out more!)

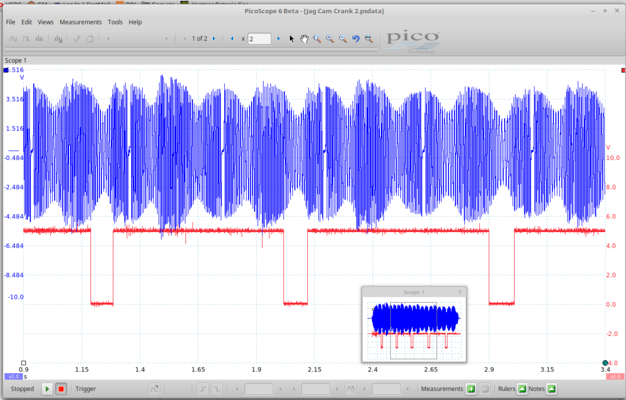

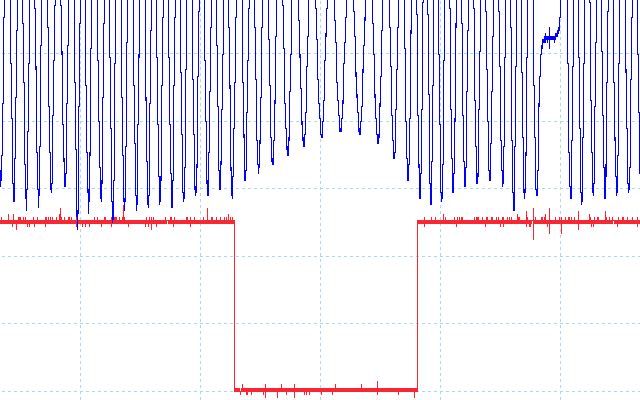

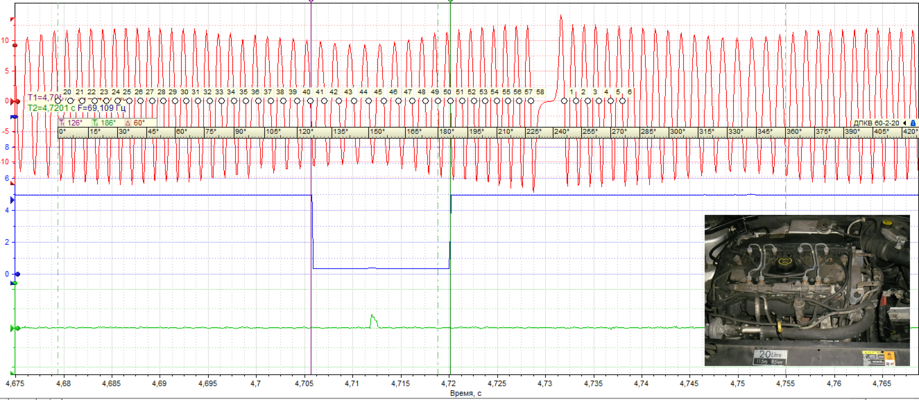

I am learning lots - inc. how to use an oscilloscope for auto diagnosis (along with all the common Jag X-type faults... that it does not seem to have!). Yes I could tear it apart further to check things, but I already know how to do that.

The parts cannon has already been fired at it by previous owner/car dealer with 5 replacement injectors (- even re-furbs are £100 each). I did spend less than a tenner each on a crank+cam sensors and a fuel filter, admittedly...

If it turns out to be something very serious (like a hole in a piston) then I take a few bits off to put on ebay and call the scrap man - it weighs 1.5T after all.

As for wiring -well this was my last project

View attachment 197284

Still learning!

Still learning!Crank - Inductive sensor on a 58 toothed wheel (behind the flywheel) witha missing toothtwo missing teeth,

No, it's standard. 58 teeth and 2 spaces so 60 per single crank revolution. The two teeth space is what the inductive sensor notices - and where you shove the crank locking pin.

Thanks @m_c I did the diesel check first as the ECU will simulate a misfire if less than 4L!

View attachment 198824

Nope, need to get the front of the engine off first, which is a few hours job. that I need daylight and not raining for...

Not sure how the DMF would affect timing ?

@RWD3M heard that from others too, but I did find it in the manual! Did it trash the fuel pump?

Nope, need to get the front of the engine off first, which is a few hours job. that I need daylight and not raining for...

Not sure how the DMF would affect timing ?

@RWD3M heard that from others too, but I did find it in the manual! Did it trash the fuel pump?

. Has a new accessory belt and tensioner on it though...

. Has a new accessory belt and tensioner on it though...