rory1

Member

- Messages

- 1,167

- Location

- Macclesfield

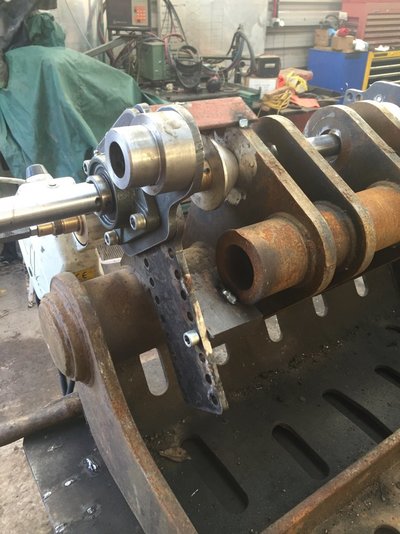

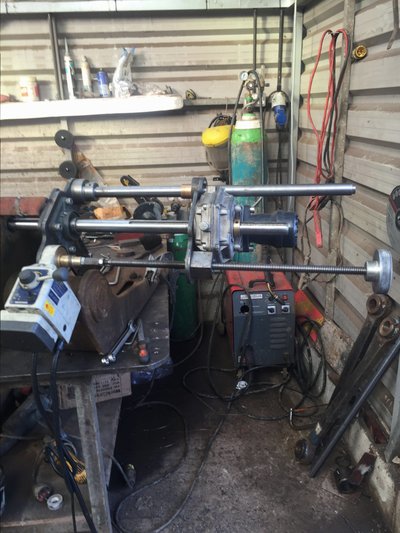

Been doing a bit of line boring on a excavator demolition grab with my home made line borer. Holes were originally 45mm in 20mm thk abrasion resistant plate. They are being bored out to 65mm and having bushes fitted.