You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

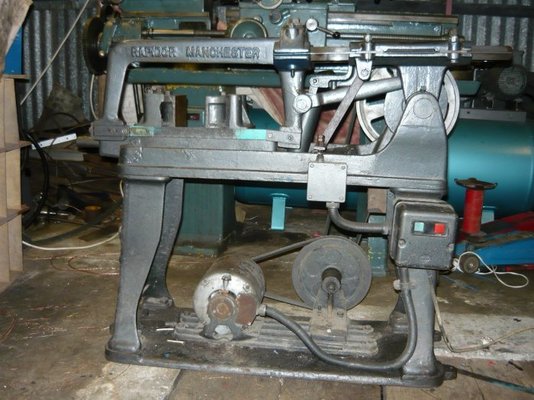

Renovating/servicing a Rapidor hacksaw

- Thread starter brewdexta

- Start date

Bear in mind some of the parts arent necessary for operation - the clutch, arm and trigger mechanism is really designed for shutting the saw off when operating from shaft drive. If you have a motor running the saw then a microswitch is probably better as the motor would remain running otherwise.

Id say they are more important if you want a restoration.

Saw is definitely looking good and will be a real workhorse for you - imagine how much work its already done and like you say - swiss watch.

Old bloke at the end of the street was telling me they used to have two fellas solely employed to work a rapidor saw on 3 shifts back when he was working in a big engineering firm in leeds. So they would be going 24 hours a day

Id say they are more important if you want a restoration.

Saw is definitely looking good and will be a real workhorse for you - imagine how much work its already done and like you say - swiss watch.

Old bloke at the end of the street was telling me they used to have two fellas solely employed to work a rapidor saw on 3 shifts back when he was working in a big engineering firm in leeds. So they would be going 24 hours a day

brightspark

Member

- Messages

- 41,461

- Location

- yarm stockton on tees

Bear in mind some of the parts arent necessary for operation - the clutch, arm and trigger mechanism is really designed for shutting the saw off when operating from shaft drive. If you have a motor running the saw then a microswitch is probably better as the motor would remain running otherwise.

Id say they are more important if you want a restoration.

Saw is definitely looking good and will be a real workhorse for you - imagine how much work its already done and like you say - swiss watch.

Old bloke at the end of the street was telling me they used to have two fellas solely employed to work a rapidor saw on 3 shifts back when he was working in a big engineering firm in leeds. So they would be going 24 hours a day

it was probably the one i bought 30 odd years ago .all the bearings were clapped out pulley and clutch missing bed and vice were worn and had to be built up with weld . plates screwed to the vice jaws vice screw clapped out guide rails i re ground. apart from that it was in good condition

it was probably the one i bought 30 odd years ago .all the bearings were clapped out pulley and clutch missing bed and vice were worn and had to be built up with weld . plates screwed to the vice jaws vice screw clapped out guide rails i re ground. apart from that it was in good condition

brewdexta

The biggest tool in the box

- Messages

- 5,768

- Location

- UK

Nice looking saw BS

Got most of it back together today after showevling a couple of tonne of FYM and other garden chores.

I just need to weld some ends on the bar for th vice, get a 1/4" BSW wing nut for the blade, put the spings back on, put the shelf and suds tray on and put the guard back on and stick it on some wheels. The guard and suds tank are being blasted so I'll make a shelf next, stick it on wheels and add the bar for the vice.

I gave it a quick go and its very quiet, wobbles a bit on the workmate so

Cheers

Andy

Got most of it back together today after showevling a couple of tonne of FYM and other garden chores.

I just need to weld some ends on the bar for th vice, get a 1/4" BSW wing nut for the blade, put the spings back on, put the shelf and suds tray on and put the guard back on and stick it on some wheels. The guard and suds tank are being blasted so I'll make a shelf next, stick it on wheels and add the bar for the vice.

I gave it a quick go and its very quiet, wobbles a bit on the workmate so

Cheers

Andy

- Messages

- 14,822

- Location

- UK

Cracking job Andy, be a shame to use it. Whats the set screw do on the front of the dash pot? Mine never had that nd i can't see one on BS's.

brightspark

Member

- Messages

- 41,461

- Location

- yarm stockton on tees

that screw would stop the saw frame from tilting up and over to far backwards ,otherwise the piston in the dashpot would pull out . no big deal but u would loose the oil. smart job are u going to use the dashpot for relief stroke on blade or not bother ?? i dont use mine and the blades dont seem to sufferCracking job Andy, be a shame to use it. Whats the set screw do on the front of the dash pot? Mine never had that nd i can't see one on BS's.

brewdexta

The biggest tool in the box

- Messages

- 5,768

- Location

- UK

Cheers guys

It's definitely going to get used so won't stay light grey for long, at least I know it works properly and I can rely on it.

I haven't had time to play with it yet so not sure what it can do. It took me a while to determine it cuts on the forward stroke so I could fit the blade correctly. How do you get it to use the dashpot on the return stroke?

Cheers

Andy

It's definitely going to get used so won't stay light grey for long, at least I know it works properly and I can rely on it.

are u going to use the dashpot for relief stroke on blade or not bother ?? i dont use mine and the blades dont seem to suffer

I haven't had time to play with it yet so not sure what it can do. It took me a while to determine it cuts on the forward stroke so I could fit the blade correctly. How do you get it to use the dashpot on the return stroke?

Cheers

Andy

MattF

Forum Supporter

- Messages

- 18,644

- Location

- South Yorkshire

How do you get it to use the dashpot on the return stroke?

It's just a damper, to give a bit of resistance against the arms downward travel.

MattF

Forum Supporter

- Messages

- 18,644

- Location

- South Yorkshire

I think BS was likely just referring to when you lift the arm up once it's completed cutting, not on the return stroke. With it being an open top pot, it'd be quite easy to accidentally lift it too high and pull the piston out of the pot.

octo0072000

Member

- Messages

- 6,004

- Location

- south yorks

wheels are not a good idea unless you want it wandering about the shop

another person on here fitted wheels bad idea unless you can remove them or lift them

another person on here fitted wheels bad idea unless you can remove them or lift them

brewdexta

The biggest tool in the box

- Messages

- 5,768

- Location

- UK

I think BS was likely just referring to when you lift the arm up once it's completed cutting, not on the return stroke. With it being an open top pot, it'd be quite easy to accidentally lift it too high and pull the piston out of the pot.

Hi Matt

I've got the pot filled with some gear oil I had spare, lowers nice and slow and as along as you don't lift the arm too fast it doesn't spew oil everwhere, at least not from the pot ;-)

I heard that some Rapidor's lift a little on the return stroke so was wondering if that what BS was referring to that along with the dashpot as implied he saved blade wear

- I guess we will have to find out from BS

- I guess we will have to find out from BS

Cheers

Andy

brewdexta

The biggest tool in the box

- Messages

- 5,768

- Location

- UK

wheels are not a good idea unless you want it wandering about the shop

another person on here fitted wheels bad idea unless you can remove them or lift them

I've bought wheels with brakes, the kind you screw into the side of the wheels so only meant to be used for occasional movement. I'll give it a go and if its no good I have a plan B

no matter where you put it in the workshop there will be a bit of steel just that bit too long. or need to be cut on the angle etc. so having the ability to move it relatively easily is appealing.

Cheers

Andy

madkayaker

Pro sparkey Pro Welder

- Messages

- 13,655

I've got mine bolted to a pallet so I move it with a pallet truck.

brewdexta

The biggest tool in the box

- Messages

- 5,768

- Location

- UK

I've got mine bolted to a pallet so I move it with a pallet truck.

I like that idea, that may be better than my plan B

I've been meaning to get a pallet truck.

brightspark

Member

- Messages

- 41,461

- Location

- yarm stockton on tees

the blade cuts on the forward stroke . if u look at the frame when its cutting it rises on the forward stroke and lowers on the return. if the dashpot is filled with oil and the piston lowers on the return it will damp the downward motion and take the weight of the frame and the blade . the piston has holes drilled through and a washer underneath spring loaded theres an adjusting rod to alter the flow of oil giving diffrent damping rates. i dont fill mine or use it as i find the blades last a long time without it as long as u use cutting fluidCheers guys

It's definitely going to get used so won't stay light grey for long, at least I know it works properly and I can rely on it.

I haven't had time to play with it yet so not sure what it can do. It took me a while to determine it cuts on the forward stroke so I could fit the blade correctly. How do you get it to use the dashpot on the return stroke?

Cheers

Andy

brewdexta

The biggest tool in the box

- Messages

- 5,768

- Location

- UK

Thanks BS

It's as I thought then, no snake oil, unless you put some in the dashpot

For a moment I thought there was a particular arm requried to be set up to make it lift on the back stroke, I have only had it moving momentrily as the reciprocating action threatens to throw it off the workmate so I haven't observed tehe lifting motion yet.

I've biscuit jointed and glued two bits of spare oak floor board together and will push it through the thicknesser when its set. I should have the shot blasted suds reservoir back soon so should be ready about the same time.

Cheers

Andy

It's as I thought then, no snake oil, unless you put some in the dashpot

For a moment I thought there was a particular arm requried to be set up to make it lift on the back stroke, I have only had it moving momentrily as the reciprocating action threatens to throw it off the workmate so I haven't observed tehe lifting motion yet.

I've biscuit jointed and glued two bits of spare oak floor board together and will push it through the thicknesser when its set. I should have the shot blasted suds reservoir back soon so should be ready about the same time.

Cheers

Andy

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,868

- Location

- East Yorkshire

I have only had it moving momentrily as the reciprocating action threatens to throw it off the workmate so

Cheers

Andy

Sounds like you need an hydraulic lift there fella