Dieselman 63

Forklift Certified

- Messages

- 5,859

- Location

- Wellington, New Zealand

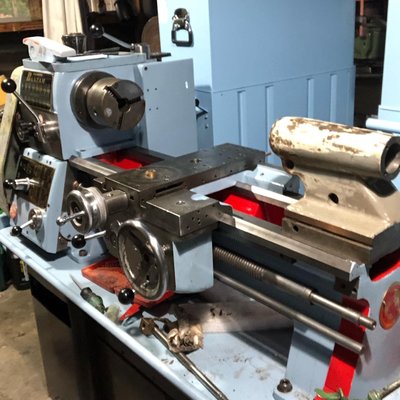

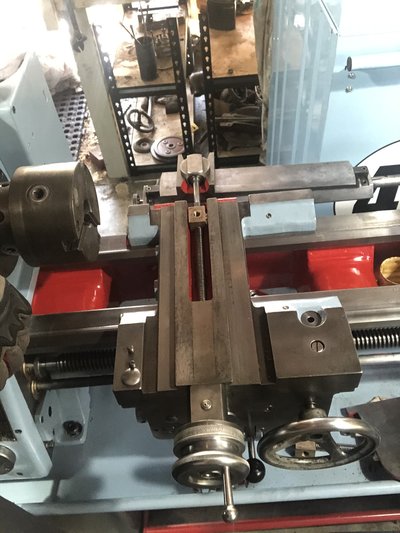

It's good to see it so near to completion. I do like the aesthetic touch with the red felt

Don't forget to paint the tail stock

Don’t you like Colchester’s light brown-grey?

It’s been good to see you getting into some more restoration with your compressor mate, I had a good read through that.