Dieselman 63

Forklift Certified

- Messages

- 5,860

- Location

- Wellington, New Zealand

I'm not going to be scraping my mill either. I don't have a big surface table and I wouldn't have the first idea where to begin.

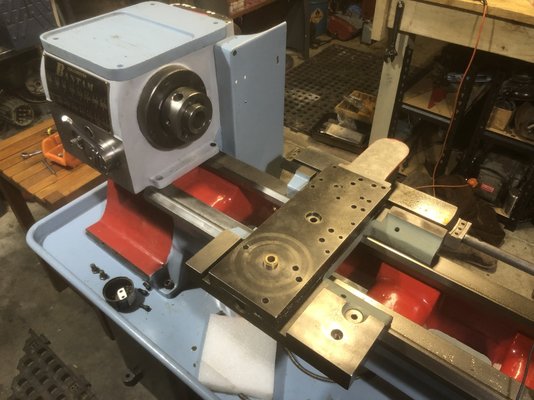

It’s an ex polytech machine made in 1975, and has sat idle since 2009 and prior to them was only used to turn plastics since 1999, so twenty years of no/little use seems good. There’s no noticeable wear on the bed and little backlash. There are a few dings on the bed where students have changed the chuck and gone ‘oops it’s a bit heavier than I thought!’ but nothing terrible.