Dieselman 63

Forklift Certified

- Messages

- 5,859

- Location

- Wellington, New Zealand

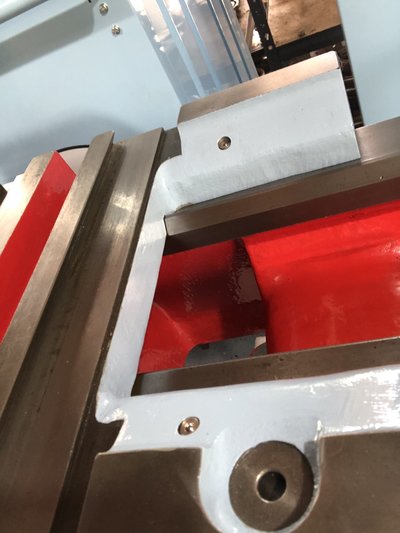

My goodness. You have worked wonders with it. Your work inspires me to progress my own restoration efforts.

Yes, it certainly helps having the online community to kick-start me into more work. I was having a play on a lathe at polytech the other day, made me want to get my own finished so I can play on one at home, too!