You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brew day!

- Thread starter Maker

- Start date

Blobber

Forum Supporter

- Messages

- 3,579

- Location

- lincolnshire

I might not comment much but I always read your updates so keep posting!New thread should get seen more, don't think anyone's still reading this, it's taken me too long.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

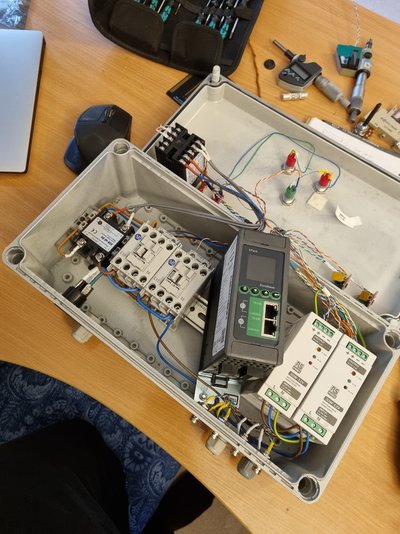

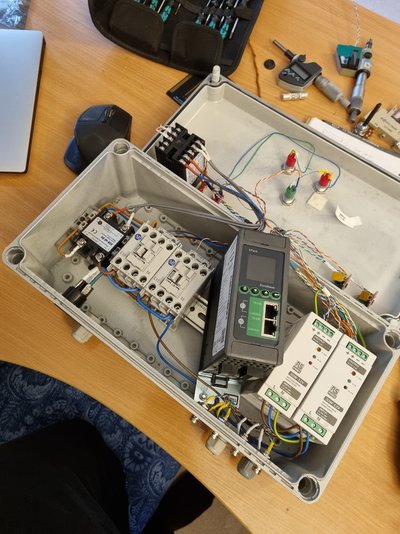

Dale very kindly sorted me out with something a bit fancier than the Chinese unit:

It's a Eurotherm EPack, basically a big thyristor with a very clever controller, it's a very nice unit and very overkill to stop a brew kettle boiling over. Doesn't quite fit but I think it's worth making room for. It's got an analogue input and a pair of digital inputs, the thinking was I'd connect a pot to the analogue input to control the set point (Power level) and the 24v signal I had fed to a contactor to a digital input to enable/disable the output (I'll have to lose a contactor to make it fit). Unfortunately, while the digital inputs are perfectly happy with 24v, the analogue one expects 0-10v, 24v very quickly cooked it. If it worked, the meter would show a few meg...

Doesn't quite fit but I think it's worth making room for. It's got an analogue input and a pair of digital inputs, the thinking was I'd connect a pot to the analogue input to control the set point (Power level) and the 24v signal I had fed to a contactor to a digital input to enable/disable the output (I'll have to lose a contactor to make it fit). Unfortunately, while the digital inputs are perfectly happy with 24v, the analogue one expects 0-10v, 24v very quickly cooked it. If it worked, the meter would show a few meg...

Luckily:

1. Only the analogue input is broken, everything else still works and it's not displaying any errors.

2. I couldn't open the case, if I could I'm quite confident I'd have fixed it till it was properly broken

3. It can be entirely controlled with ModbusTCP...

Here's the workaround then:

The Raspberry Pi reads the position of the pot, using an ADC module because it's GPIO is only digital, and it changes the setpoint on the EPack using modbus. It's massive overkill, both using modbus, and a Raspberry Pi, for such a simple task (starting to see a theme here ) but it works and leaves lots of room for upgrading (Think Pi running PID loops, controlling mash steps, an HMI...).

) but it works and leaves lots of room for upgrading (Think Pi running PID loops, controlling mash steps, an HMI...).

For now it works, I need to buy another Pi as I've borrowed this one from my HiFi (A Pi Zero would be perfect if it had Ethernet), tidy the code a little, tidy the wiring a lot and fit it all in the enclosure, and that will be the brewery controller (Gen.1 ) completed.

) completed.

It's a Eurotherm EPack, basically a big thyristor with a very clever controller, it's a very nice unit and very overkill to stop a brew kettle boiling over.

Doesn't quite fit but I think it's worth making room for. It's got an analogue input and a pair of digital inputs, the thinking was I'd connect a pot to the analogue input to control the set point (Power level) and the 24v signal I had fed to a contactor to a digital input to enable/disable the output (I'll have to lose a contactor to make it fit). Unfortunately, while the digital inputs are perfectly happy with 24v, the analogue one expects 0-10v, 24v very quickly cooked it. If it worked, the meter would show a few meg...

Doesn't quite fit but I think it's worth making room for. It's got an analogue input and a pair of digital inputs, the thinking was I'd connect a pot to the analogue input to control the set point (Power level) and the 24v signal I had fed to a contactor to a digital input to enable/disable the output (I'll have to lose a contactor to make it fit). Unfortunately, while the digital inputs are perfectly happy with 24v, the analogue one expects 0-10v, 24v very quickly cooked it. If it worked, the meter would show a few meg...

Luckily:

1. Only the analogue input is broken, everything else still works and it's not displaying any errors.

2. I couldn't open the case, if I could I'm quite confident I'd have fixed it till it was properly broken

3. It can be entirely controlled with ModbusTCP...

Here's the workaround then:

The Raspberry Pi reads the position of the pot, using an ADC module because it's GPIO is only digital, and it changes the setpoint on the EPack using modbus. It's massive overkill, both using modbus, and a Raspberry Pi, for such a simple task (starting to see a theme here

) but it works and leaves lots of room for upgrading (Think Pi running PID loops, controlling mash steps, an HMI...).

) but it works and leaves lots of room for upgrading (Think Pi running PID loops, controlling mash steps, an HMI...).For now it works, I need to buy another Pi as I've borrowed this one from my HiFi (A Pi Zero would be perfect if it had Ethernet), tidy the code a little, tidy the wiring a lot and fit it all in the enclosure, and that will be the brewery controller (Gen.1

daleyd

Member

- Messages

- 10,392

- Location

- Wrexham, North Wales

Great stuff Adam, I perhaps should have been a bit more descriptive about the analogue input!!

Well done on getting the pi running and communicating!! I fear rather than helping I may have lead you down a rabbit hole with this ha ha ha

Well done on getting the pi running and communicating!! I fear rather than helping I may have lead you down a rabbit hole with this ha ha ha

brewdexta

The biggest tool in the box

- Messages

- 5,747

- Location

- UK

I think the link didn't paste, probably influenced by home brew and fat fingers on my phone. The above link will add Ethernet to a pi zero for 8 quid.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

I was probably going to get that same Ethernet SPI module and make a hat to hold both that and the ADC. It looks like there's a big shortage of Pi's at the moment, the only one not sold out is the 4, no Zero W's to be found for sensible money anywhere.

brewdexta

The biggest tool in the box

- Messages

- 5,747

- Location

- UK

I was probably going to get that same Ethernet SPI module and make a hat to hold both that and the ADC. It looks like there's a big shortage of Pi's at the moment, the only one not sold out is the 4, no Zero W's to be found for sensible money anywhere.

I had the same issue, I wanted a cheap pi as a one wire receiver for the boiler room temperatures, I ended up buying a pi4 with 4Gb which is overkill. I may be able to juggle around some of my older pi and make one spare and use this for other projects.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

I'm debating keeping the 3B for the brewery and getting a 4 for the hifi, the plan was always to get an external DAC, OLED screen and make a proper little network streamer with playback controls. Need the right Tuit for that though, a bare board and the onboard audio has worked fine for 18 months.

brewdexta

The biggest tool in the box

- Messages

- 5,747

- Location

- UK

I'm using a hifi-berry amp, they have just DAC too. They have some arrangement with Bang and Olufsen and they have an image for rpi including a streamer. I have a 7" touch screen on it but the web interface is better, I use it to stream radio 6 music and spotify but it has airplay etc. etc.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

Can't persuade anyone to drive me and the kegs over to Brad's place so I'm persevering with the dodgy stick welder. This time I didn't drill the hole until I'd welded the nipple on, that way there's no edge to melt back. I set the welder to about 10A, the hot start is probably around 50A which is enough to stick the nipple on in a load small tacks. Looks alright, admittedly I did only take a picture of the best side.  I'm well aware it's nothing like a full penetration weld but it's strong enough to hold back 500mm of water and that's all it really needs. There'll also be a small crevice inside so not the most hygienic weld, but no worse than a BSP thread...

I'm well aware it's nothing like a full penetration weld but it's strong enough to hold back 500mm of water and that's all it really needs. There'll also be a small crevice inside so not the most hygienic weld, but no worse than a BSP thread...

Pipe assembled. The vertical part has an extension because I need it to clear the bench top, but I don't want a long pipe welded straight on in case I change how it's all set up.

In position, I should have made the extension about half an inch longer, I've had to put the valve on it's side to fit it into the bench.

That's the mash tun all done, quite happy with that.

I'm well aware it's nothing like a full penetration weld but it's strong enough to hold back 500mm of water and that's all it really needs. There'll also be a small crevice inside so not the most hygienic weld, but no worse than a BSP thread...

I'm well aware it's nothing like a full penetration weld but it's strong enough to hold back 500mm of water and that's all it really needs. There'll also be a small crevice inside so not the most hygienic weld, but no worse than a BSP thread...

Pipe assembled. The vertical part has an extension because I need it to clear the bench top, but I don't want a long pipe welded straight on in case I change how it's all set up.

In position, I should have made the extension about half an inch longer, I've had to put the valve on it's side to fit it into the bench.

That's the mash tun all done, quite happy with that.