You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have fixed today

- Thread starter qwakers

- Start date

brightspark

Member

- Messages

- 41,416

- Location

- yarm stockton on tees

Moved the drill press off of the bench top:

not much clearance by the time you lift the vice up and you put a drill bit in for metal to clear the bench top

Far too tidy

Can't have it any other way, I simply don't get enough time in the mancave to be anything else. Being away all week in the wagon means I have limited time for projects so I prefer to spend that time usefully rather than wasting it looking for tools or tripping over junk that's littering the floor. And in my opinion walking into a clean and tidy workshop is much more conducive to maximum efficiency and productivity.

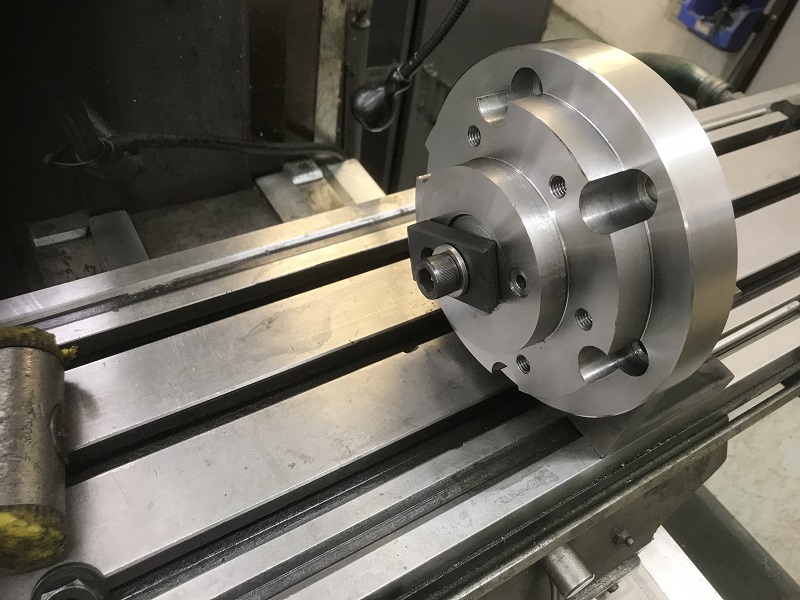

I managed to rescue a chuck adaptor that I've been making (A2-6 to A2-5 including two hydraulic oil galleries.

I's broken a long series 6 mm drill 60 mm below the surface, but eventually succeeded in burning it out using my sinker EDM - a long process!

I's broken a long series 6 mm drill 60 mm below the surface, but eventually succeeded in burning it out using my sinker EDM - a long process!

Got this wee 25l Kaeser compressor off @eLuSiVeMiTe

Sorted the pressure gauge & air intake, new oil, splodge of paint running sweet. Fits under the bench

Sorted the pressure gauge & air intake, new oil, splodge of paint running sweet. Fits under the bench

slim_boy_fat

Member

- Messages

- 29,187

- Location

- Scottish Highlands

Sorted the pressure gauge & air intake, new oil, splodge of paint running sweet. Fits under the bench

Nice work, looks like a completely different machine!

TBH I pretty much stripped it, then as well as the above, redid the wiring to the start cap, valves checked, some odd additions to the air intake set back to standard and a lot of polishing/cleaning.Nice work, looks like a completely different machine!

Emailed Kaeser in Germany and their distributor in the UK sent me parts lists, diags, manuals, the lot.

Imagine trying to get that for a 40yr old machine from China!

Danez

Never late in a V8!

- Messages

- 673

- Location

- Lancashire, England

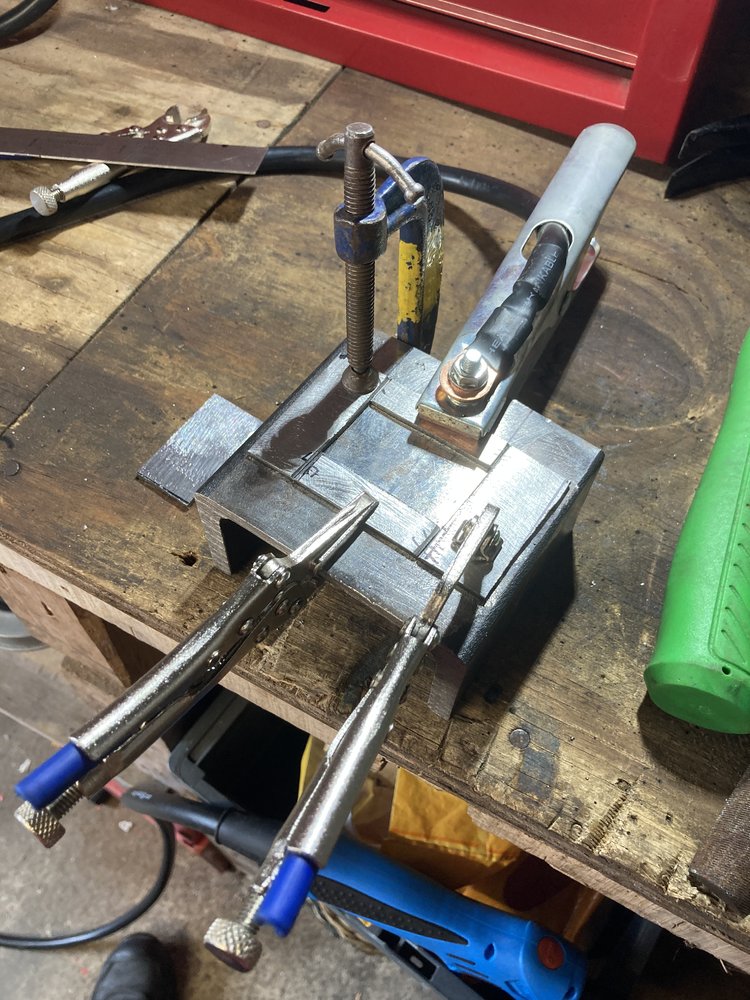

Original switch for my draper pillar drill gave up the ghost years ago and couldn’t find one online so bought a generic one which was a bit too small.

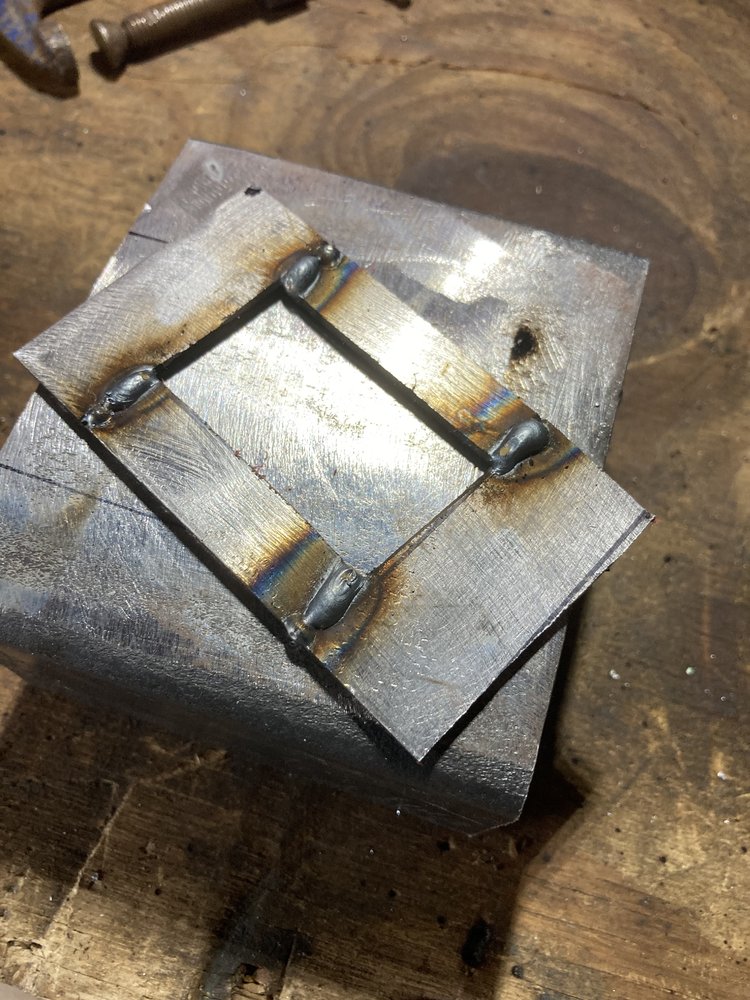

so using this as an excuse to practise my welding skills i made an adaptor plate for it. first time welding with gas

the bolts in the plate arnt aligned as the original tapped holes in the drill itself were way out!

started with some CAD (cardboard aided design)

so using this as an excuse to practise my welding skills i made an adaptor plate for it. first time welding with gas

the bolts in the plate arnt aligned as the original tapped holes in the drill itself were way out!

started with some CAD (cardboard aided design)

The_Yellow_Ardvark

I'm a citizen of Legoland travellin' incommunicado

- Messages

- 20,248

- Location

- Going Away.

Nice work.Original switch for my clarke pillar drill gave up the ghost years ago and couldn’t find one online so bought a generic one which was a bit too small.

so using this as an excuse to practise my welding skills i made an adaptor plate for it. first time welding with gas

the bolts in the plate arnt aligned as the original tapped holes in the drill itself were way out!

started with some CAD (cardboard aided design)

View attachment 297022

View attachment 297018View attachment 297019View attachment 297020View attachment 297021

But I have a spare.

They are good drills, the V bely is a 10mm wide belt at the top.

Danez

Never late in a V8!

- Messages

- 673

- Location

- Lancashire, England

can't complain, inherited it from my grandad, it's served me well! and good to know in case i need a new beltNice work.

But I have a spare.

They are good drills, the V bely is a 10mm wide belt at the top.

next job is to weld a little bracket I can secure to the bench to hold me welding gun

Nick DV

"That's the only name they ever gave me."

- Messages

- 1,732

- Location

- "A long time ago in a galaxy far, far away...."

Far too tidyView attachment 296495

Can't have it any other way, I simply don't get enough time in the mancave to be anything else. Being away all week in the wagon means I have limited time for projects so I prefer to spend that time usefully rather than wasting it looking for tools or tripping over junk that's littering the floor. And in my opinion walking into a clean and tidy workshop is much more conducive to maximum efficiency and productivity.

Bobupndown

What could possibly go wrong?

- Messages

- 1,997

- Location

- Northern Ireland

We did it at gcse level CDT (craft design and technology as it was called in 1990) Also did mechanical and electrical engineering national diploma for 2 years after that, sadly never touched a lathe ever since, wouldn't know where to begin to use one now.Screwcutting is not difficult. You just need to understand what it is you're trying to achieve and the steps you go through to get there.

I felt the same as we were not allowed to do it at O level metal work. You had to wait until A level for that, which sadly I never did.

JMS1972

Member

- Messages

- 1,197

- Location

- NW Leicestershire, UK

The new to me bandsaw has had some TLC.

Gear box had some goop in it that didn't look much like grease worrying amount of flakes too. Cleaned it out and added some Moly.

worrying amount of flakes too. Cleaned it out and added some Moly.

I'm hoping that will slow down the demise of the gears..

Need to replace the blade as it has a dodgy part somewhere but still cuts

Gear box had some goop in it that didn't look much like grease

worrying amount of flakes too. Cleaned it out and added some Moly.

worrying amount of flakes too. Cleaned it out and added some Moly.I'm hoping that will slow down the demise of the gears..

Need to replace the blade as it has a dodgy part somewhere but still cuts

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,492

- Location

- The Shed of Danger, surrey, England

Forgot to take pics, but a mate dropped in to see whether I could look at one of his Bluetooth earbugs and on-the-handlebars wireless phone charger... that had both gone intermittent. Blimey those earbugs are cramped! Usual thing, bad solder joints on the only bits done by a human, and a component lead cut *just* too short... Fiddly-simples

Solder wick works a lot better with flux, when it's years old!

Dave H. (the other one)

Solder wick works a lot better with flux, when it's years old!

Dave H. (the other one)

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

As I've just relocated the contents of our storage unit to the new garage, presently there's nowhere to put a workbench. Your photo here has given me the inspirationView attachment 296495

........................................ And in my opinion walking into a clean and tidy workshop is much more conducive to maximum efficiency and productivity.

to think out of the box and put it in front of the roll up door.

to think out of the box and put it in front of the roll up door.

Why didn't think of that.

Why didn't think of that.I recently put new 80w transmission oil back in mine. Is moly better?The new to me bandsaw has had some TLC.

View attachment 297475

Gear box had some goop in it that didn't look much like greaseworrying amount of flakes too. Cleaned it out and added some Moly.

View attachment 297476

I'm hoping that will slow down the demise of the gears..

Need to replace the blade as it has a dodgy part somewhere but still cuts

JMS1972

Member

- Messages

- 1,197

- Location

- NW Leicestershire, UK

Moly is better than nothing which is what it had in it!I recently put new 80w transmission oil back in mine. Is moly better?

I have no idea if its better than transmission oil but I had a big tub of Moly to hand so that is what it got.....

Maker

Most folk just call me; Orange Joe

- Messages

- 10,646

- Location

- Keeler crater

Fixed my Raspberry Pi.

It runs "Raspotify", which claims to be A Spotify Connect client "that just works", and to be fair to them, it did for nearly a year. For no apparent reason it stopped connecting last night. Tried rebooting it, reinstalling Raspotify, reflashing the OS, flashing the latest OS, (desktop and headless). After about six hours it just happened to start working again.

Still, far cheaper than a proper network streamer.

It runs "Raspotify", which claims to be A Spotify Connect client "that just works", and to be fair to them, it did for nearly a year. For no apparent reason it stopped connecting last night. Tried rebooting it, reinstalling Raspotify, reflashing the OS, flashing the latest OS, (desktop and headless). After about six hours it just happened to start working again.

Still, far cheaper than a proper network streamer.

Last edited: