You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Hood

Member

- Messages

- 17,984

- Location

- Carnoustie, Scotland

Before I headed home I made up a bracket to fit the digital scale to the tailstock. I then chucked up a bit of 30mm thick 4.25" dia aluminium and turned the OD to 100mm and bored out the inside to 58.42mm and parted off 20mm thick.

Then onto the Chiron for a bit of milling and I ended up with this collar.

Fitted it to the quill and it works great even though I bought the wrong orientation scale

Then onto the Chiron for a bit of milling and I ended up with this collar.

Fitted it to the quill and it works great even though I bought the wrong orientation scale

Melvyn Best

Member

- Messages

- 1,955

- Location

- Cambridge

If I had legs like that I would have them amputatedThe last time I saw legs like that they was hanging out of the edge of a nest

northwest

Searching for the Holy Grail.........

- Messages

- 6,669

- Location

- Manchester UK

Before I headed home I made up a bracket to fit the digital scale to the tailstock. I then chucked up a bit of 30mm thick 4.25" dia aluminium and turned the OD to 100mm and bored out the inside to 58.42mm and parted off 20mm thick.

Then onto the Chiron for a bit of milling and I ended up with this collar.

View attachment 285063

Fitted it to the quill and it works great even though I bought the wrong orientation scale

View attachment 285064

View attachment 285065

I have had one of those to fit to the tailstock of the Harrison on the shelf to the side for four years waiting to be fitted. Well I see no point in rushing these jobs.......

selectedgrub

Member

- Messages

- 3,511

- Location

- New Zealand

Stripped some wire and braided.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,329

- Location

- Near to Cross Hands Llanelli SouthWales GB

I wonder how long it will be before the reading is / can be horizontally read rather than vertical on such digital scales ?Before I headed home I made up a bracket to fit the digital scale to the tailstock. I then chucked up a bit of 30mm thick 4.25" dia aluminium and turned the OD to 100mm and bored out the inside to 58.42mm and parted off 20mm thick.

Then onto the Chiron for a bit of milling and I ended up with this collar.

View attachment 285063

Fitted it to the quill and it works great even though I bought the wrong orientation scale

View attachment 285064

View attachment 285065

Or am I still living in the past ? .

Or am I still living in the past ? .

Hood

Member

- Messages

- 17,984

- Location

- Carnoustie, Scotland

They do have them, I just ordered the wrong one.I wonder how long it will be before the reading is / can be horizontally read rather than vertical on such digital scales ?

Or am I still living in the past ? .

Here is the horizontal one.

You can also get remote readouts for them.

Or you can get ones without the local readout and just the remote.

northwest

Searching for the Holy Grail.........

- Messages

- 6,669

- Location

- Manchester UK

Present for someone.

View attachment 284583

Been a few years since I last made one, I'm quite pleased with it.

Would be really nice if you could make a bit of a thread on how you made that. I am sure someone will be along in a second to one of the youtbe vids but I would be more interested in your approach. Very nice that.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,687

- Location

- Keeler crater

I took a few pictures of the process, I'll write something up in a bit.Would be really nice if you could make a bit of a thread on how you made that. I am sure someone will be along in a second to one of the youtbe vids but I would be more interested in your approach. Very nice that.

I had some good results with silverflow 55 brazing with mapp recently so had another go at the er40 collet chuck. Well it sticks, took a bloody lot of heat and still was not quite hot enough to flow properly. Ive got some ideas, I might try reheating it tomorrow, but I think itll be good enough. Does mean I'll need to face and recut the taper.

View attachment 284756

the whole thing would need to be remachined, you'll be amazed at how much distortion there will be from silver soldering/brazing

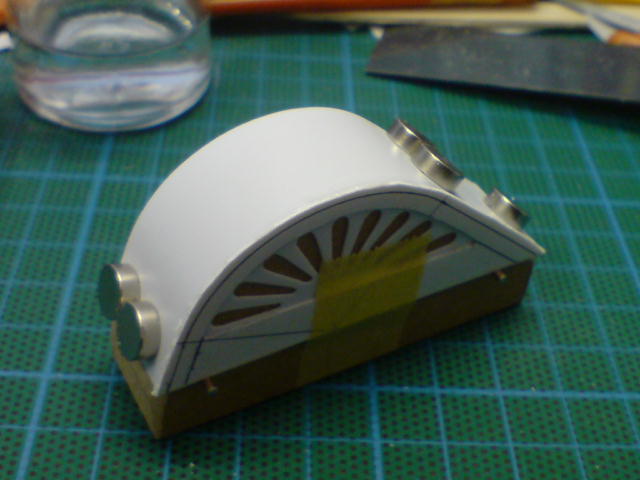

sometimes its the little things that make you happy, like making a jig for for sticking two bits of plastic together. on the model boat Im making I need to make some paddle boxes for covering the paddle wheels. as the paddle wheels are 46mm diameter this was a bit fiddley to do accurately. so I thought I'd make a simple jig to do it.

so the shape of the paddle box was machined onto a priece of MDF. if it was larger I would have done it freehand on a disc sander.

then add a few screws so that I can use magnets to hold the sheet styrene in place, and pins to locate the bottom of the sides, and chamfer the sides of the mdf so that it wont be glued to the styrene.

hold the top in place with magnets and tape the side in place, so that you can apply the styrene cement to both edges

and then just stick together......takes longer to do, but much better than trying to hold it with your fingers

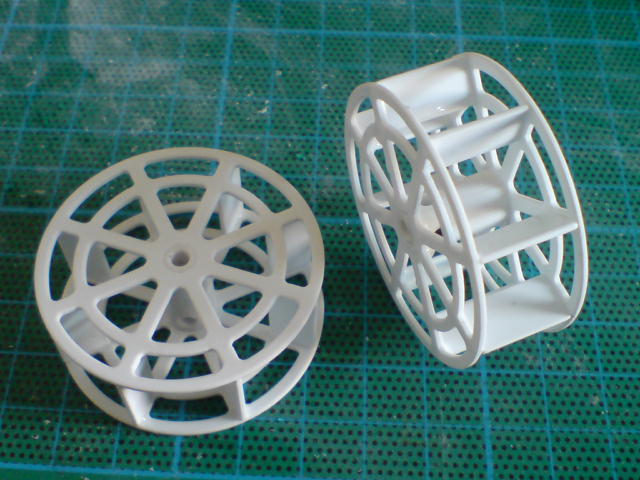

and a paddle wheel, the sides where milled from sheet on a rotary table

so the shape of the paddle box was machined onto a priece of MDF. if it was larger I would have done it freehand on a disc sander.

then add a few screws so that I can use magnets to hold the sheet styrene in place, and pins to locate the bottom of the sides, and chamfer the sides of the mdf so that it wont be glued to the styrene.

hold the top in place with magnets and tape the side in place, so that you can apply the styrene cement to both edges

and then just stick together......takes longer to do, but much better than trying to hold it with your fingers

and a paddle wheel, the sides where milled from sheet on a rotary table

Kram

Member

- Messages

- 8,380

- Location

- Sussex

Yes I got some in the taper so it will need to be recut, Im not sure about distortion, it wasnt a problem last time - I was still able to indicate with no significant runout on the taper or od.the whole thing would need to be remachined, you'll be amazed at how much distortion there will be from silver soldering/brazing

Afternoon stripping the last paint from the little bike tank, some surface rust on the weld seems came off easy with wire brush.

Its not in bad condition for a 29 year old bike.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,329

- Location

- Near to Cross Hands Llanelli SouthWales GB

My wife asks ...what is the gate made of steel , alu or stainless ? I said it looks like mild steel that's been electo galv'ed or aluminium paint sprayed . So please tell us as the suspense if frightening .

Brad93

Member

- Messages

- 19,430

- Location

- Essex, United Kingdom

Better than galv in many cases

MattF

Forum Supporter

- Messages

- 18,354

- Location

- South Yorkshire

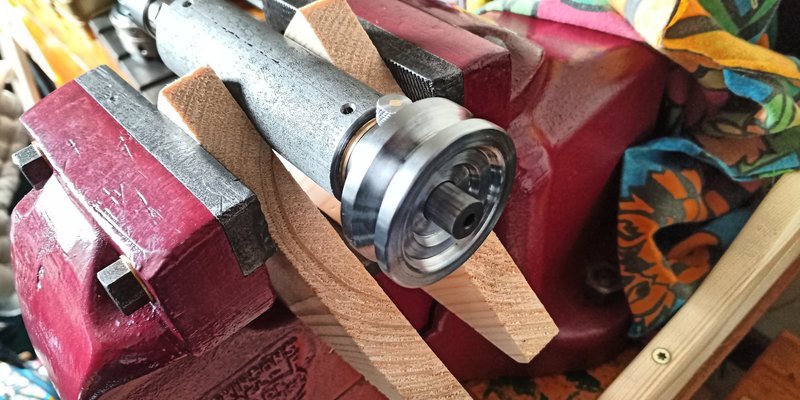

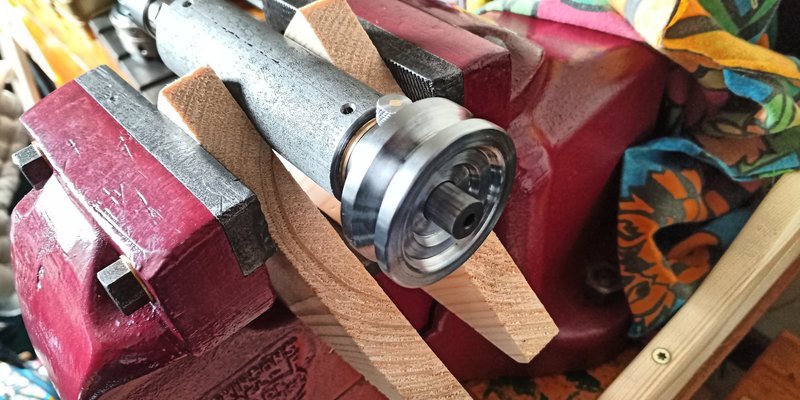

Body made from a piece of this:

Not perfect, but it'll act as a tester for revisionII.

That pulley was a cow to make, on my lathe. Had to get creative to work around the lathes limitations. Made from steel, not aluminium.

The screw & oil holes are drilled by hand, (still no pillar drill yet), so no picking on misalignment.

Not perfect, but it'll act as a tester for revisionII.

That pulley was a cow to make, on my lathe. Had to get creative to work around the lathes limitations. Made from steel, not aluminium.

The screw & oil holes are drilled by hand, (still no pillar drill yet), so no picking on misalignment.