- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

Morris

Forum Supporter

- Messages

- 2,224

- Location

- Northamptonshire.

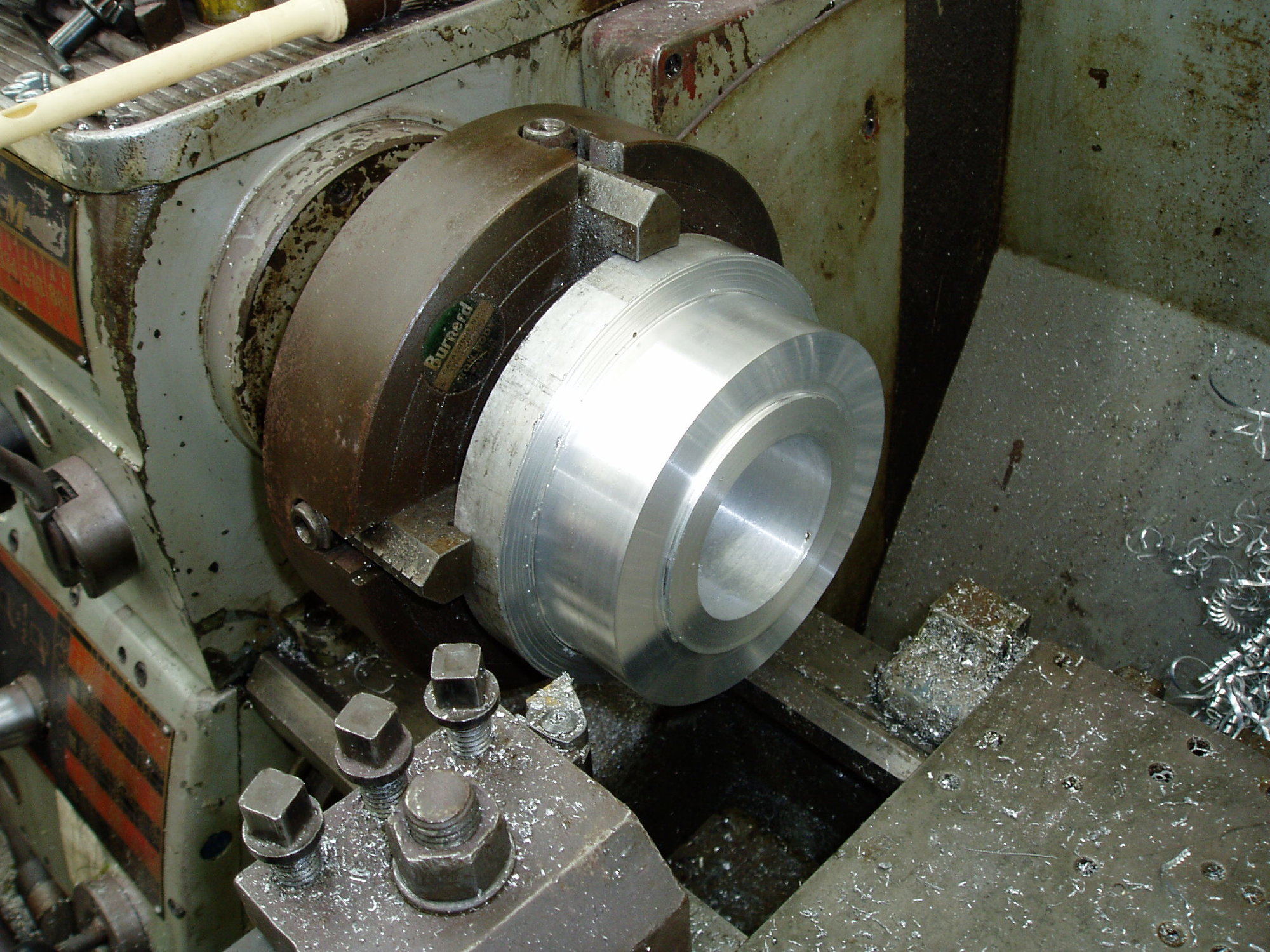

Currently machining a front clutch piston for a Torqueflite 904 due to being a tad clumsy with the original. Can't find a second hand one and new ones seem extinct.

Roughing out at the moment, doing a bit now and then between other stuff.

Roughing out at the moment, doing a bit now and then between other stuff.

Kram

Member

- Messages

- 8,460

- Location

- Sussex

It fits my shed and accurate enough. Without the motor upgrade it was rubbish, but apart from that I think chinese 10" lathes all about the same. A good used Harrison would be better, this only makes sence with limited space.

Anyway the 14TR2 thread not perfect. I did not bottom out the insert as I thought I was past full depth, so I think it needs to go back in for another cut. The split nut is tight (on and off) normal way round. If I put it on split end first it is free spinning

Marker pen rubs off the root.

Anyway the 14TR2 thread not perfect. I did not bottom out the insert as I thought I was past full depth, so I think it needs to go back in for another cut. The split nut is tight (on and off) normal way round. If I put it on split end first it is free spinning

Marker pen rubs off the root.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

It fits my shed and accurate enough. Without the motor upgrade it was rubbish, but apart from that I think chinese 10" lathes all about the same. A good used Harrison would be better, this only makes sence with limited space.

Anyway the 14TR2 thread not perfect. I did not bottom out the insert as I thought I was past full depth, so I think it needs to go back in for another cut. The split nut is tight (on and off) normal way round. If I put it on split end first it is free spinning

Marker pen rubs off the root.

Is that the left hand thread you did with the right hand insert?

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

What’s a edge tailstock alignment bar?It came out perfectly, en16 is a lovely material.

Like you I don't mess about with the compound, straight in.

Bed. To be honest I never perfected it so it's about time.

Got an edge tailstock alignment bar for the tailstock.

I just turn a piece same diameter as tailstock barrel and clock across. Good way of measuring tailstock sled wear as well

Kram

Member

- Messages

- 8,460

- Location

- Sussex

Ground these two holders down so they wont hit the tailstock center next time. There was contact when threading but not enough to knock the center out. While I was at it I reground this carbide boring bar. The old tip too small to grind so ground it back to the shaft.

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

What’s a edge tailstock alignment bar?

I just turn a piece same diameter as tailstock barrel and clock across. Good way of measuring tailstock sled wear as well

It's just a bar with centres and a ground diameter on each end.

https://www.edgetechnologyproducts.com/tailstock-alignment-bar/

Maker

Most folk just call me; Orange Joe

- Messages

- 10,649

- Location

- Keeler crater

How much!?!It's just a bar with centres and a ground diameter on each end.

https://www.edgetechnologyproducts.com/tailstock-alignment-bar/

I'm pretty sure I've seen DoubleBoost do it with a length of 10mm stud with big washers on each end.

I'm pretty sure I've seen DoubleBoost do it with a length of 10mm stud with big washers on each end.

daleyd

Member

- Messages

- 10,437

- Location

- Wrexham, North Wales

Important job on this morning - we picked up a globe light for my daughter that someone was throwing away and it was missing a plastic bushing.

Only one thing to do.... unfortunately I only had steel bar in that kind of diameter so the bush weighs about as much as the rest of the lamp combined, but at least it’s now usable and spins.

Only one thing to do.... unfortunately I only had steel bar in that kind of diameter so the bush weighs about as much as the rest of the lamp combined, but at least it’s now usable and spins.

Ton-up

Member

- Messages

- 2,349

- Location

- Essex, England.