You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Typical stuff I do

- Thread starter anto44

- Start date

anto44

Member

- Messages

- 1,921

- Location

- ireland

Majority of custom stuff is rubbish, made as quickly and easily as possible for maximum profit.How do you feel when you go on car forums and see someone’s pictures of their new custom exhaust but all you see is a load of pre-formed pipes routed here, there and everywhere because the builder doesn’t have a pipe mandrel?

anto44

Member

- Messages

- 1,921

- Location

- ireland

I get them off a local engineering company, most of the suppliers here don't seem interested in dealing with small orders.Where are you buying the dairy bends here Anto ? Reynolds ?

ronan

Member

- Messages

- 11,282

I get them off a local engineering company, most of the suppliers here don't seem interested in dealing with small orders.

True, which is why i buy most stuff i want mail order from the uk.

anto44

Member

- Messages

- 1,921

- Location

- ireland

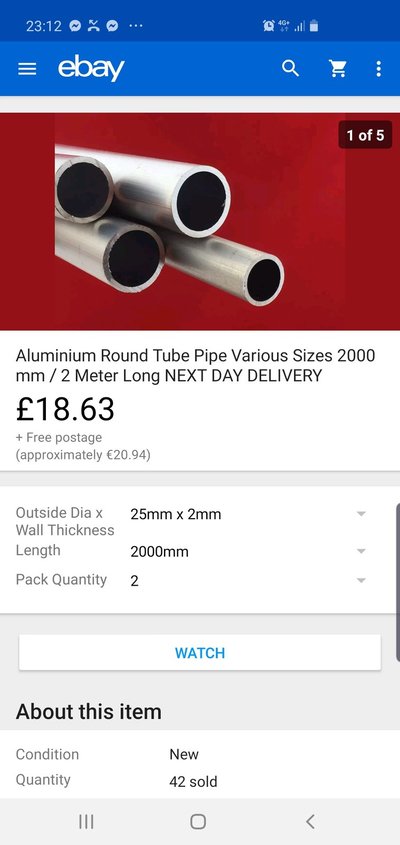

Most of my fittings come from the uk, I buy a lot of pipe off of Ebay. For stuff like a 500mm length of 10mm od 8mm id stainless or aluminium pipe for hose fittings on tanks, it's cheaper than anywhere I can find local. If they haven't got it in stock it's buy a full length and wait for when ever their delivery is or get stuffed.True, which is why i buy most stuff i want mail order from the uk.

stuvy

Member

- Messages

- 9,202

Turbo or NA

All 50’s to late 70’s

There all on carbs due to pre 63 fia rules but exhausts are mostly a pair of dual 3-1 then a massive dual silencer for noise regs here and abroad

anto44

Member

- Messages

- 1,921

- Location

- ireland

You have to be a lot more careful with NA carbed stuff especially, you'll definitely need your carbs retuned after any sort of exhaust modification.All 50’s to late 70’s

There all on carbs due to pre 63 fia rules but exhausts are mostly a pair of dual 3-1 then a massive dual silencer for noise regs here and abroad

From the manifold back isn't too bad to do. Are you looking to change exhausts due to needing replacement or to tune the engine? Making a new manifold for a carbed NA is an art form, getting screaming top end redline power is easy, it's getting a good useable power curve with nice midrange that takes a lot of skill

whm_fab

Motorsport engineering

- Messages

- 429

- Location

- in the shop

keep up the good work anto.

ive a tip for you though, to save you time and work - what your doing is no problem, but you seem to be doing an aweful lot of measuring, and cutting the pipe that way will tend to bow the blade, especially starting on a bend which im sure you found was a nightmare.

do you have a stiff vertical setup for your bandsaw?

i primarily do a lot of thin wall SS and inconel manifolds for race cars, and with that of course is loads of collectors that ive to cut similar to what you are doing.

you will get better results, less blade wear and fast by ssetting your bandsaw up vertical, and feeding the tube in from the end of the tube first up to the bend (oposite to the way you are cutting)

i have simple jigs made up on a feed plate for different diameter tubes, pop them in the jog on the plate, lock it in place, and feed it into the blade from the open end.

worth thinking about

ive a tip for you though, to save you time and work - what your doing is no problem, but you seem to be doing an aweful lot of measuring, and cutting the pipe that way will tend to bow the blade, especially starting on a bend which im sure you found was a nightmare.

do you have a stiff vertical setup for your bandsaw?

i primarily do a lot of thin wall SS and inconel manifolds for race cars, and with that of course is loads of collectors that ive to cut similar to what you are doing.

you will get better results, less blade wear and fast by ssetting your bandsaw up vertical, and feeding the tube in from the end of the tube first up to the bend (oposite to the way you are cutting)

i have simple jigs made up on a feed plate for different diameter tubes, pop them in the jog on the plate, lock it in place, and feed it into the blade from the open end.

worth thinking about

Munkul

Jack of some trades, Master of none

- Messages

- 7,763

- Location

- Cumbria

How do you feel when you go on car forums and see someone’s pictures of their new custom exhaust but all you see is a load of pre-formed pipes routed here, there and everywhere because the builder doesn’t have a pipe mandrel?

Doing it that way is just fine, as long as the pipes are purged properly and aligned correctly. The weld join is almost seamless intermally when done right....

anto44

Member

- Messages

- 1,921

- Location

- ireland

When I got this saw I built a table for it to run vertical but I could never get it to work well. Used horizontal the saw is perfect, never throws a blade, never breaks a blade blade and cuts perfectly square, used vertically it just wants to jump the blade off constantly. I decided not to mess around any more with trying to get it to run vertical as I had it dialed in as close to perfect as I could for horizontal and didn't want to ruin that. After watching videos of people using your method to do it in a vertical bandsaw I've been on the lookout for one, unfortunately vertical metal cutting bandsaws are like hens teeth in Ireland. I recently missed out on this one.keep up the good work anto.

ive a tip for you though, to save you time and work - what your doing is no problem, but you seem to be doing an aweful lot of measuring, and cutting the pipe that way will tend to bow the blade, especially starting on a bend which im sure you found was a nightmare.

do you have a stiff vertical setup for your bandsaw?

i primarily do a lot of thin wall SS and inconel manifolds for race cars, and with that of course is loads of collectors that ive to cut similar to what you are doing.

you will get better results, less blade wear and fast by ssetting your bandsaw up vertical, and feeding the tube in from the end of the tube first up to the bend (oposite to the way you are cutting)

i have simple jigs made up on a feed plate for different diameter tubes, pop them in the jog on the plate, lock it in place, and feed it into the blade from the open end.

worth thinking about

To stop the blade wandering when starting on a curve like that I'll gently lower the blade down with the saw running and just barely touch the pipe to mark it. Then I take a small square needle file and file a small flat spot where the blade has touched so the blade has a flat spot to start on, then I just guide the blade down by hand very slowly until it's established itself cutting straight. It'd be way easier to cut in from the other end like you do though.

whm_fab

Motorsport engineering

- Messages

- 429

- Location

- in the shop

yeah i know, ireland is totally crap for decent older machine tools, we were not a manufacturing country like the uk. anything like lathes, mills, treadle guillotines, press breaks etc are hard to find here, and when you do they are abused and over priced.

There is nothing wrong with what you are doing, it just sounds very time and labour intensive - but i guess if you're not doing it all the time as a living there is no problem with that either

There is nothing wrong with what you are doing, it just sounds very time and labour intensive - but i guess if you're not doing it all the time as a living there is no problem with that either

anto44

Member

- Messages

- 1,921

- Location

- ireland

Yeah it is very time consuming doing it this way, I stay away from manifolds for this exact reason, I don't have an efficient way of doing this type of joint as of yet. I do plan on getting something more suitable for this type of cut but until then this is the best I can do with what I haveThere is nothing wrong with what you are doing, it just sounds very time and labour intensive - but i guess if you're not doing it all the time as a living there is no problem with that either