mike 109444

Member

- Messages

- 4,859

I did. Just sold it before Christmas as the girls had outgrown it.Didn't Brewdexter build one of these?

Manual wheelchairs and Class 2 vehicles are those with an upper speed limit of 4 mph (6 km/h) and are designed to be used on pavements. Class 3 vehicles are those with an upper speed limit of 8 mph (12 km/h) and are equipped to be used on the road as well as the pavement.

Couple of point to be aware of with the motor. In your post 15 the second pic, the device mounted to the right hand end of the motor (with the sticker on) is a brake. It need power to release and if you try applying power to just the motor without powering the brake (thin white wires) then the motor won't turn (may fry!). You can remove it (couple of screws) or if you use the control console from the scooter this should operate it. Also the motor/axle assembly should have a release leaver (usually red) that disengages the drive allowing a scooter to be wheeled without the drive stopping it. If you can keep this lever as it allows pushing of the unit. The axle unit is (or should be!) a differential unit an so will suffer the one will spinning while other does not drive. It is possible to "lock" the diff.

I used one of these drive units for my bead roller, hence locking the diff ! and red lever allows manual feeding when needed.

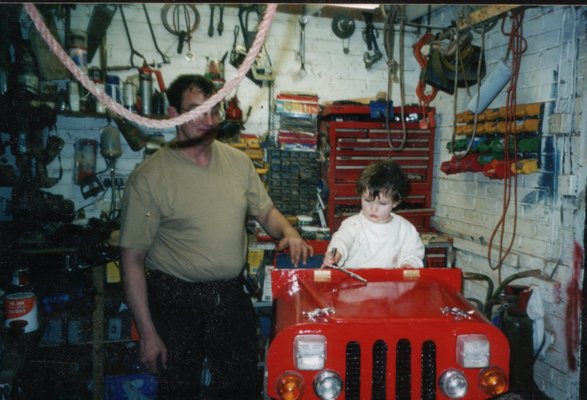

Back in 1999 I built the "willies Jeep" version, the plans were fantastic.

Then I had access to a place were I could get copies made, what I used as the "working plans"

The rear axil, gear box and motor was from a disability scooter, at first using 2 X 12volt 17Ah batteries. Soon upgraded to 32ah.

Steering was real hoge poge of parts, go cart, mobility scoter and parts I made.

It was painted fire engine red, it looked good.

It even had a full set or working lights and rod activated brakes.

Mini me used until she was 4 years old and grew out of it.

Fun days.

The last rebuild I fitted a old lawn mower engine to it.

Saddly I can not locate the pictures of the original build I know they are in the house some were. On 35mm film and pictures.

I do have one of Mini Me and I rebuilding the engine.

View attachment 134119

Thanks for sharing, if the pics ever turn up please get them posted. Would love to see it.

Sorry, I misread your initial post, thought you were talking from an aesthetic point of view. Now I understand, and yes good point. I forget that rather than a ‘scale model’ this is actually a kids toy. Saving grace is, the tailgate is secured by anti-luce pin so it’s quite difficult for little fingers to open, especially whilst moving, but I agree a potential exists with all pointy hooky things so better remove it...

I did. Just sold it before Christmas as the girls had outgrown it.

http://www.mig-welding.co.uk/forum/threads/painting-a-wooden-land-rover.46597/

Rest of the build is on the Toylander forum.

I bucked the trend and soaked the MR MDF with low viscosity epoxy boat builders resin before painting. It's very wet in the Pennines

Very nice build by the way

Cheers

Andy

Just had a quick run through your thread, looks a top job. How did you get on with the resin? Any particular brands to look for? Cheers

it took a few days to completely dry but for memory it was cold at the time which helped with working time.

it took a few days to completely dry but for memory it was cold at the time which helped with working time.@Calvin7 Is this going to be a surprise for your children, or do they know it's coming?

Is it made of ginger bread?

Nice build thread by the way and I also like your garage doors, I'd like some like that on my new workshop hopefully!