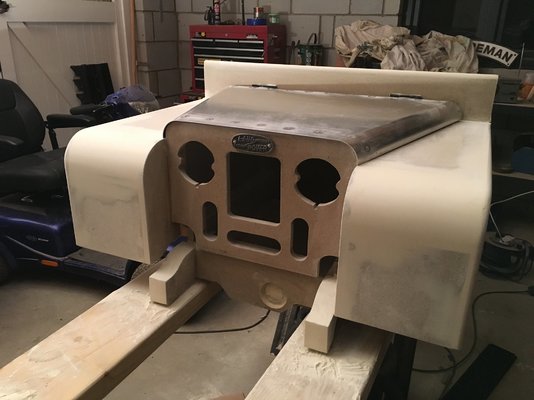

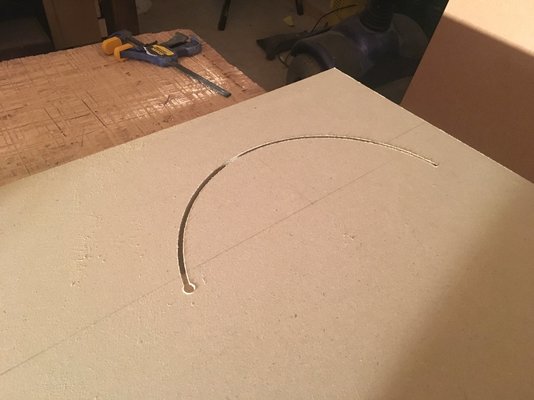

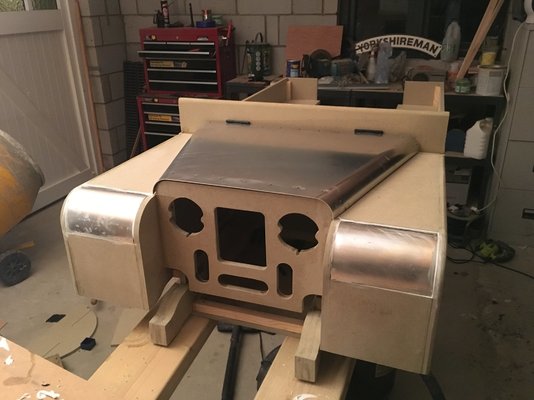

Hello all, here’s my build thread for the ‘Toylander 1’ ride-on children’s car, I’m making for my twin boys. The plans are around £45 delivered, and based on a 1948 Landrover Series 1. More info available here.

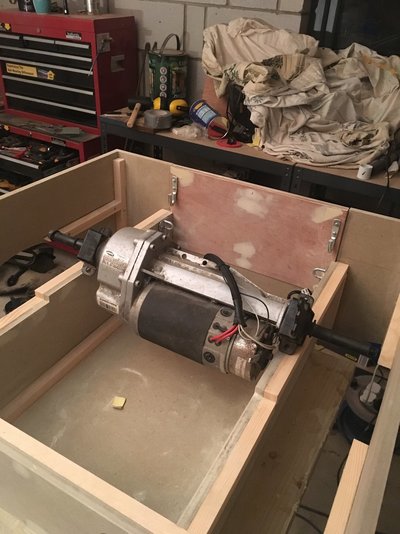

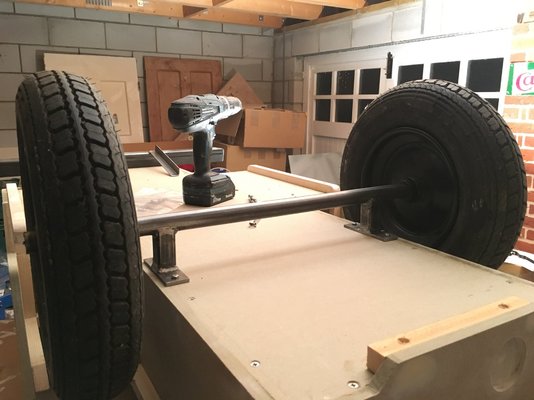

There are plenty of build threads online already, however most seem to never finish, or miss photos of the good bits. Especially as I’m using a mobility scooter motor transaxle, making the thing ‘go’ could require some thought, and support, so a thread here seems like a good idea for myself and future builders.

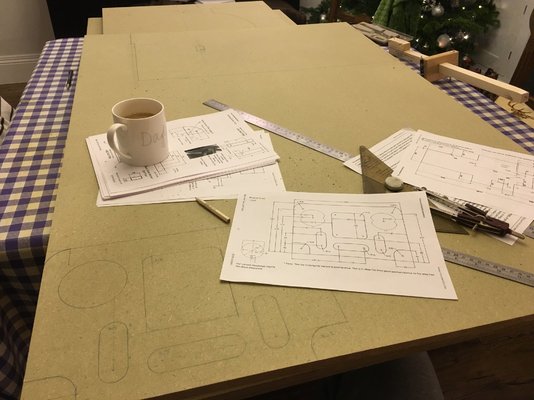

I requested the plans for Christmas 2016 however only got round to making a start in December 2017. Ive ordered steering wheel, lights, and windscreen kit from Toylander, and although everything is available from Toylander, I will fabricate a lot myself.

First few posts will cover where I am to-date, then it will slow down as I contend with work and life to get in the garage.

Cheers, Clav.

There are plenty of build threads online already, however most seem to never finish, or miss photos of the good bits. Especially as I’m using a mobility scooter motor transaxle, making the thing ‘go’ could require some thought, and support, so a thread here seems like a good idea for myself and future builders.

I requested the plans for Christmas 2016 however only got round to making a start in December 2017. Ive ordered steering wheel, lights, and windscreen kit from Toylander, and although everything is available from Toylander, I will fabricate a lot myself.

First few posts will cover where I am to-date, then it will slow down as I contend with work and life to get in the garage.

Cheers, Clav.

. I like the look of that and will follow your progress.

. I like the look of that and will follow your progress.

. I think I'd have removed the hook ends of the tailgate supports, welded on a ring and fitted a pair of these links - all sizes are available

. I think I'd have removed the hook ends of the tailgate supports, welded on a ring and fitted a pair of these links - all sizes are available