Pete.

Forum Supporter

- Messages

- 15,042

- Location

- Kent, UK

The y axis screw is a beefy screw which is driven manually through a bevel drive from the handwheel or in auto-feed by a reversing bevel gearbox operated by a lever on the side of the machine near the top.

Here's the screw, it's in fantastic condition, not surprising since it's constantly spalsh-fed gearbox oil. Note the keyway in the end that picks up drive from the auto-feed gear.

Big chunky bronze nut with backlash adjusters. The middle bolt jacks the halves apart and the two end bolts pull them in at either end. To adjust the nut you loosen the middle bolt, pinch up the ends to achieve your desired backlash/sticktion then tighten the middle bolt again.

Grub screw to give access for adjusting the nut. Hasn't been out in an age.

And here's the assembly in place and how to adjust the nut.

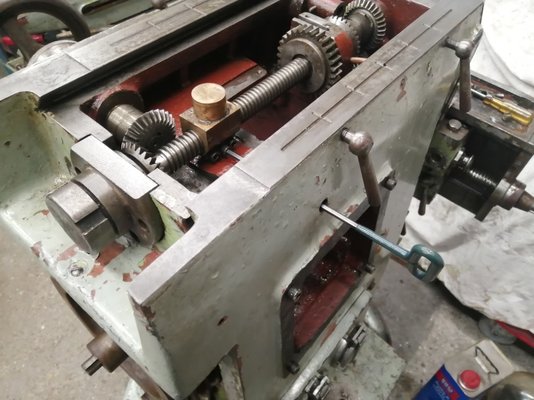

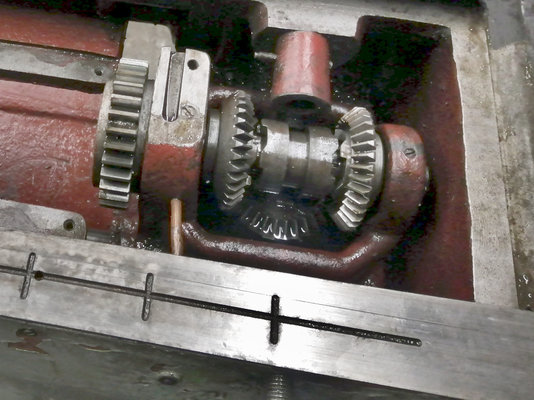

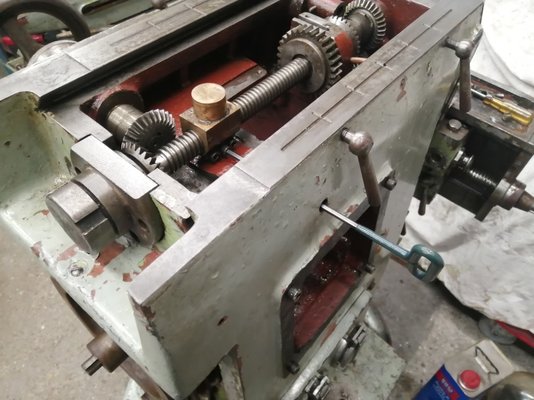

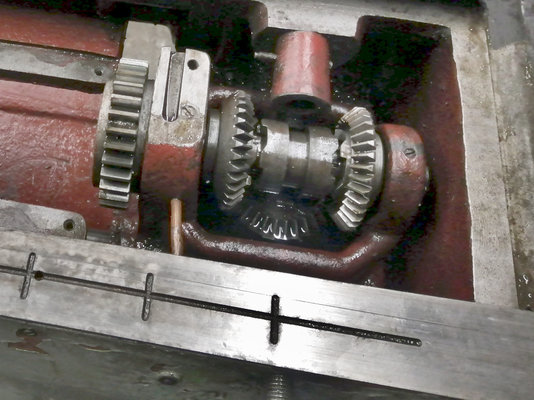

The end of the screw slides into the shaft of the auto-feed control gears and takes it's drive from a key slot. The two bevel gears are free-spinning on the shaft and turn with the bottom gear which is driven by a vertical shaft from the gearbox in the machine base. The dog clutch slides either way to engage in or out for the axis. The big gear on the left is just an idler that takes drive from the gearbox below and transfers it to the spindle above. The slot in the housing next to the big gear is for the retaining fork for the spindle sliding gear.

This is the spindle gear above that meshes with the idler. It slides on the spindle spline and is held in place with a fork which must be removed before you can take the top slide off. It is held by a single bolt and comes out by tapping the base out of the slot - it only comes out one way as I discovered after a good bit of trying.

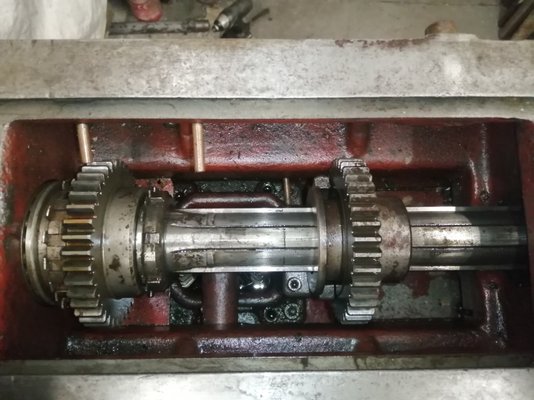

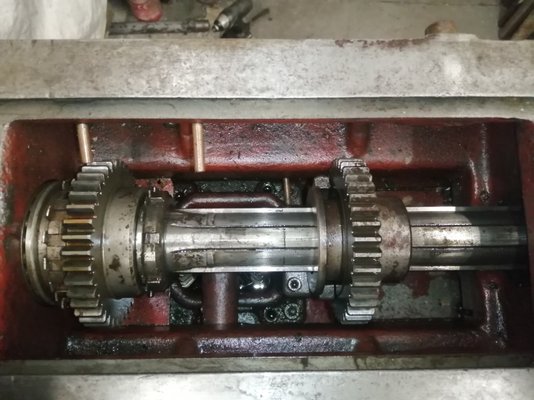

The spindle assembly as viewed from above. Sliding gear on the right that brings drive to the spindle. Fixed gear on the left that drives the milling or slotting head.

Here's the screw, it's in fantastic condition, not surprising since it's constantly spalsh-fed gearbox oil. Note the keyway in the end that picks up drive from the auto-feed gear.

Big chunky bronze nut with backlash adjusters. The middle bolt jacks the halves apart and the two end bolts pull them in at either end. To adjust the nut you loosen the middle bolt, pinch up the ends to achieve your desired backlash/sticktion then tighten the middle bolt again.

Grub screw to give access for adjusting the nut. Hasn't been out in an age.

And here's the assembly in place and how to adjust the nut.

The end of the screw slides into the shaft of the auto-feed control gears and takes it's drive from a key slot. The two bevel gears are free-spinning on the shaft and turn with the bottom gear which is driven by a vertical shaft from the gearbox in the machine base. The dog clutch slides either way to engage in or out for the axis. The big gear on the left is just an idler that takes drive from the gearbox below and transfers it to the spindle above. The slot in the housing next to the big gear is for the retaining fork for the spindle sliding gear.

This is the spindle gear above that meshes with the idler. It slides on the spindle spline and is held in place with a fork which must be removed before you can take the top slide off. It is held by a single bolt and comes out by tapping the base out of the slot - it only comes out one way as I discovered after a good bit of trying.

The spindle assembly as viewed from above. Sliding gear on the right that brings drive to the spindle. Fixed gear on the left that drives the milling or slotting head.