DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Next time you want to cut a stud off a long threaded bolt . all thread rod or a long screw , fill the thread you want keeping with nuts and lock nut the end nuts to the next flat so all flats align then pop it in the vice & use an angle grinder or hack saw to cut it . Insert studs using the same lock nut method .My colleague asked two weeks ago if I could lend him my engine driven welder.

He has to fix his gate in a property in woods, no power over there.

So I propose him to go there together cause my engine driven is completely mechanical, no fancy electronics to control it, an engine and an alternator.

Last time I've used my GenSet she was running poorly and it made me struggle.

So today once back from work I've removed the carb for cleaning, lots of rust powder in it belonging from the tank.

I've cleaned the bowl, the jets, butterfly valves, the internal passages and the venturi tube.

External will stay dirty till I have the time to address the thing properly.

But I've decided to repair the stud's threads.

So used my new to me tap wrench and just because I won't to dig out my drill and tapping box (with the good stuff in it) I've used my cheap sae metric set .

So tapped the holes to M6x1mm no problem.

I've then ruined a stud because I wasn't able to get the die chasing the threads correctly.

And ruined the other one because I didn't think how to loosen the nut once prolonged the threads which go into the carb .

So time for new studs I guessed.

Took two M6 screws but had to cut them to length.

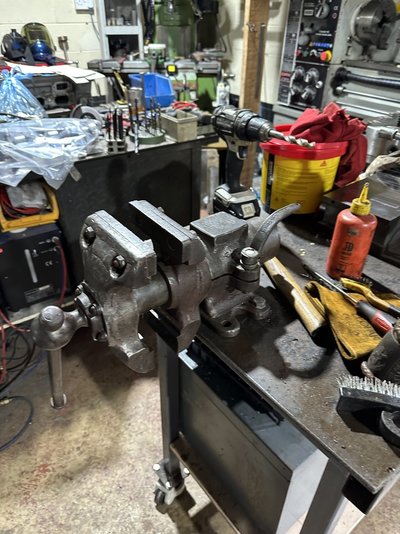

How to clamp them in the vice?

I've had little bit of brainstorming as I didn't have a nut long enough to use another screw to keep it still .

And broken a die too because I have to buy expensive stuff and not be cheap buying cheap sets .

So I've took a nut and splitted with an hacksaw.

Cleaned the threads put the screw in and tightened the nut in the vice.

It worked very well the nut clamped onto the screws without ruining the threads.

Again hacksaw, cut to length.

Unscrew little bit, champhered the edge with a file stroking anticlockwise around the threads.

Did it twice...

Cleaned them up with the die.

Loctite on the stud, Loctite in the threaded hole, screwed the stud in and tightened them up.

Anyways here the results.

I'll let the Loctite cure over night and hopefully tomorrow after work in the evening I'll be able to put it back together and test the welder if it solved the problem as it most likely had an air leak because of those studs

View attachment 463053