smoggyrich

Member

- Messages

- 144

i hope you have somebody fire watching the inside for you too many bits to set fire to on a camper your welding is a lot better than when you first started on the front end

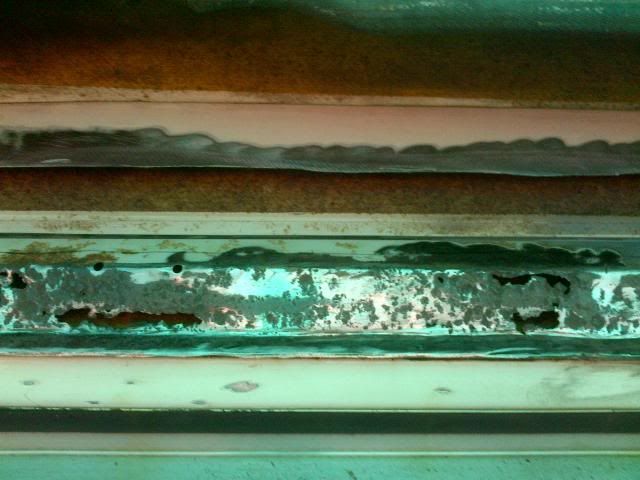

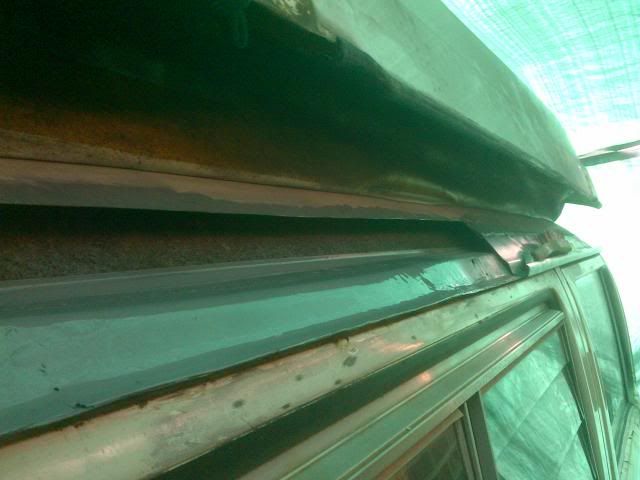

that's one of the problems with the lifting top it traps water also never put the roof away wet if you can avoid

i would renew the edge seal on the roof too that's the only bit that stops the rain etc getting in

looking good have you got to do the whole side or is it just the front end that's bad

I have been working alone so I've been working with a fire extinguisher handy at all times.

I have a new seal to go on and new hinges (stainless).

It's bad the whole length of the hinge side of the roof.

I know what you mean about the roof being a water trap. It's required attention for a few years. Wish I hadn't left it so long but it gives me something to keep me out of trouble!!!