You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Restoring my 97 Mitsubishi FTO - Beginner so any help and feedback welcomed

- Thread starter Cosantoir

- Start date

Myles1970

Member

- Messages

- 927

- Location

- Monaghan, Ireland

You could use a piece of 2-3mm plate to bend it over, to keep the gap uniform with the originalHonestly I was going to skip it I kind of had it in my head that the lip doubled over on itself is just asking to rust later (although the rest of the shield will probably go first.)

I might get the vice grips and fold it over.

Ha this is true.

Would I get away with just putting another strip of material flat in line with the top edge and do an edge joint?

Thinking if I was to do that it would probably be best to have a little more material sticking up on the new material side for more heat dispensation and doing a lap joint.

Would I get away with just putting another strip of material flat in line with the top edge and do an edge joint?

Thinking if I was to do that it would probably be best to have a little more material sticking up on the new material side for more heat dispensation and doing a lap joint.

Myles1970

Member

- Messages

- 927

- Location

- Monaghan, Ireland

Hahaha... One of the dangers of posting your work on here lolWhat I hear is .... Dan quit being lazy

What I did deep was drill through the floor pannel itself woops.... No idea how I would be supposed to plug weld now of I was planning to put this back on the piece I removed it from?

Gonna try copy the Japanese dudes video and try to fab this in sections with realistic bends that I (think) I can manage.

Once you see the below you're gonna say why take up welding because my calling is clearly art...

But in thinking bottom sheet can be made from a single piece,

Top piece the blue and then the yellow the side panel.

I was going to ask if I could skip element's of the fork up the top but this is for the jacking point so I assume this to probably add more strength to the floor and rigidity to the overall piece. So I'm gonna try keep these in.

@Myles1970 how did you add the dipped section to the floor pannel you did? I'd like to try replicate that dimple in the top middle piece just below that fork.

Gonna try copy the Japanese dudes video and try to fab this in sections with realistic bends that I (think) I can manage.

Once you see the below you're gonna say why take up welding because my calling is clearly art...

But in thinking bottom sheet can be made from a single piece,

Top piece the blue and then the yellow the side panel.

I was going to ask if I could skip element's of the fork up the top but this is for the jacking point so I assume this to probably add more strength to the floor and rigidity to the overall piece. So I'm gonna try keep these in.

@Myles1970 how did you add the dipped section to the floor pannel you did? I'd like to try replicate that dimple in the top middle piece just below that fork.

Myles1970

Member

- Messages

- 927

- Location

- Monaghan, Ireland

What I did deep was drill through the floor pannel itself woops.... No idea how I would be supposed to plug weld now of I was planning to put this back on the piece I removed it from?

I'd clamp them together as tight as possible and use a backing piece... Then just work your way around the circle, at least you're guaranteed full penetration

.... If you can't get clamps to reach use clecos or nuts and bolts in the adjacent holes to the one you're welding

.... If you can't get clamps to reach use clecos or nuts and bolts in the adjacent holes to the one you're weldingGonna try copy the Japanese dudes video and try to fab this in sections with realistic bends that I (think) I can manage.

Once you see the below you're gonna say why take up welding because my calling is clearly art...

Stunning!

But in thinking bottom sheet can be made from a single piece,

Top piece the blue and then the yellow the side panel.

I'd be in agreement,

...but that's how I'd do it...cut a piece to the shape of the red square (it isn't, I know) bend at the dotted line, fab the green, bending where possible, and weld the green onto the red. You can cut out the'infill' afterwards.... check out Fitzee's video here

Do you mean this:I was going to ask if I could skip element's of the fork up the top but this is for the jacking point so I assume this to probably add more strength to the floor and rigidity to the overall piece. So I'm gonna try keep these in.

@Myles1970 how did you add the dipped section to the floor pannel you did? I'd like to try replicate that dimple in the top middle piece just below that fork.

I made a lollipop stick from some 2mm, clamped the sheet onto it and worked my way slowly around it with a hammer and blunted bolster.

Hope this makes sense

... failing that, there's sure to be someone along soon who actually knows what they're doing

The lollypop stuck approach that's the one...

Looking at how you have it here I guess it'll be much easier to weld together and then I can cut out the underside of the fabricated section afterwards. This will have more material and less chance of blowing through when welding the two pieces together.

I forgot that I need near perfect connection between the two pieces when plug welding so it'll be a challenge to line these up again that we'll but I guess I could use the back of a hammer to push them together one plug at a time maybe even cheat a little and throw a tack or something to hold it in place I donno

Looking at how you have it here I guess it'll be much easier to weld together and then I can cut out the underside of the fabricated section afterwards. This will have more material and less chance of blowing through when welding the two pieces together.

I forgot that I need near perfect connection between the two pieces when plug welding so it'll be a challenge to line these up again that we'll but I guess I could use the back of a hammer to push them together one plug at a time maybe even cheat a little and throw a tack or something to hold it in place I donno

Not much to show today but second trailing arm is out and by god everything in the drivers side was an absolute nightmare and had to be cut out or sheared so yay I get to drill out plenty of bolts and re-tap them.

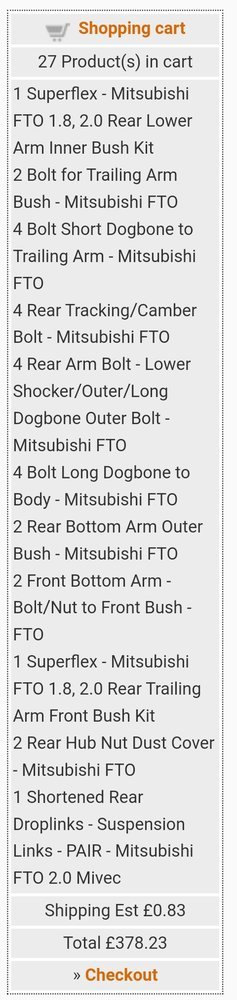

I've ordered all my new poly bushings, OEM nuts & bolts along shortened droplinks and hub covers. Ultra racing ARB's are on my radar but I've more braces in mind so good to hold out to try purchase them all together.

Now I'll get the control arms & trailing arms out I'll get these cleaned down over the coming days and then it's time to paint these and the wish bones before I get them back in the car.

I've ordered all my new poly bushings, OEM nuts & bolts along shortened droplinks and hub covers. Ultra racing ARB's are on my radar but I've more braces in mind so good to hold out to try purchase them all together.

Now I'll get the control arms & trailing arms out I'll get these cleaned down over the coming days and then it's time to paint these and the wish bones before I get them back in the car.

So a little progress today.

I finally made good of my threat to finally paint the wishbones in epoxy primer.

I'll give this a day or two to dry and harden and then I'll sand it down before top coating with some black.

Next up is a bit of CAD work on the outrigger as soon as I started the boss called me to hang some curtain rails so didn't get too far. Happy wife happy life and all that.

I noticed that the chasis rail bends so the top piece you here won't do with simple bend in the vice.

It doesn't look like much but even with cardboard you can see it's well off

A quick cut there on the apex of the bend and we're all good.

Then I could lay the cardboard out flat on some sheet to get a template to cut.

Tomorrow I'll cut out the template AND DRASTICALLY TRY to remember that this is a mirror template and not bend it in the wrong direction. But I'm thinking I can get a lot of the template mocked up from this one

I finally made good of my threat to finally paint the wishbones in epoxy primer.

I'll give this a day or two to dry and harden and then I'll sand it down before top coating with some black.

Next up is a bit of CAD work on the outrigger as soon as I started the boss called me to hang some curtain rails so didn't get too far. Happy wife happy life and all that.

I noticed that the chasis rail bends so the top piece you here won't do with simple bend in the vice.

It doesn't look like much but even with cardboard you can see it's well off

A quick cut there on the apex of the bend and we're all good.

Then I could lay the cardboard out flat on some sheet to get a template to cut.

Tomorrow I'll cut out the template AND DRASTICALLY TRY to remember that this is a mirror template and not bend it in the wrong direction. But I'm thinking I can get a lot of the template mocked up from this one

So the misses decided during my week off to do the car that I should do a patio!

So happy wife happy life. Nearly there but will be tomorrow before I get this finished and back at the car.

This is just a mock up at this stage but I'll start bringing it down to the actual size and shape soon. But I want to get the top part and angle's right first and I think I might have already I've trimmed it too tight already to have enough wiggle room.

So happy wife happy life. Nearly there but will be tomorrow before I get this finished and back at the car.

This is just a mock up at this stage but I'll start bringing it down to the actual size and shape soon. But I want to get the top part and angle's right first and I think I might have already I've trimmed it too tight already to have enough wiggle room.

So didn't like the section I made so went at it again today.

Removed the welds along the front edges by folding it. And then the I welded it to another box section I made and it was a lot easier to create.

Welded in place and it's starting to take shape.

I'm looking forward to trimming it to shape and removing any excess material.

SO... FORGOT TO PRESS POST.

So I've this all but done just gotta seam seal and prime. (Should I drill the holes for ug welding now or wait until I can align it on the car?)

Removed the welds along the front edges by folding it. And then the I welded it to another box section I made and it was a lot easier to create.

Welded in place and it's starting to take shape.

I'm looking forward to trimming it to shape and removing any excess material.

SO... FORGOT TO PRESS POST.

So I've this all but done just gotta seam seal and prime. (Should I drill the holes for ug welding now or wait until I can align it on the car?)