I was in a conundrum with how to handle the jog direction and decided on this to keep the panel simple , I can set it up like that if I need. Plan is with this mock panel to use it in anger whilst I learn the lathe and tweak so it gives the optimal user experience before commiting to having the final panel printed. I haven't tapped much on lathe I made a knob the other day with an M8 Tap and did it by hand which was fine I imagine I could have used the jog on it but small taps may well be unsuitable as you say.

- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Harrison M250 Restoration

- Thread starter R-D-R

- Start date

It's looking fantastic. I like the slave panel for the vfd, great for fault finding. The panel is looking superb, very uncluttered.

Thanks, just the Spindle speed display and switch for coolant to go on so I think there is more than enough room to spread the 6 on the right out a little more. The Slave panel is cute and means total access too all 300 odd parameters without going into the enclosure which is nice. It is IP55 rated but I think I'm going to look for an acrylic flip down cover for it, it will be flush mounted on the final panel.

Next jobs - add braking resistor and tune the braking performance, wire up the power on button.

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

Sounds like my house. Except my youngest who is the only one still at home is usually in there with me.

My 11 year old daughter was helping me last night she filed the hole to fit the rj45 connector through for the Slave panel and stripped the wires for the lights.

Quite sad but we have a walkie talkies for communication around the property. I have one permanently in the garage And was answering my sons questions about homework as I was doing it.

The other daughter then came down for a demonstration of the buttons and was suitably impressed

Mrs RDR still doesn’t understand why I want a machine that makes things round.

Quite sad but we have a walkie talkies for communication around the property. I have one permanently in the garage And was answering my sons questions about homework as I was doing it.

The other daughter then came down for a demonstration of the buttons and was suitably impressed

Mrs RDR still doesn’t understand why I want a machine that makes things round.

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

My daughter also likes being in the workshop. She helped me make a lead screw nut from acetal a while back. My youngest son loves it too.

These kind of things are not just about workshop time, it's also helps kids think things through which crosses over into other aspects of their lives.

When they get interested it's a double edge sword, I'll often get

"You could have have put this here and it would make this bit easier"

"Haven't you got and any homework to do?"

When they get interested it's a double edge sword, I'll often get

"You could have have put this here and it would make this bit easier"

"Haven't you got and any homework to do?"

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

I agree 100% with that sentiment. Even if my son and daughter choose to do something different to engineering, they learn skills surrounding literacy, numeracy, problem solving and logical thought as well as a precise attitude when in the workshop.

My eldest son has no real interest in engineering. He has a history degree and is studying music now, he's a musician. He is very precise and methodical with his music and looks after his guitars incredibly well. He has them tuned to perfection. That attitude comes from the workshop.

My eldest son has no real interest in engineering. He has a history degree and is studying music now, he's a musician. He is very precise and methodical with his music and looks after his guitars incredibly well. He has them tuned to perfection. That attitude comes from the workshop.

addjunkie

Member

- Messages

- 14,614

- Location

- Northumberland. Reet oot in the sticks

I have one lasting memory of my daughter in the garage with me.

She walsed through, saying, ah youve broke it. I had a load of bits that wouldnt go back together. I said come on then smart bottom...

She picked the bits up, looked at them, 2 minutes later, there you go, and walked out!

She did service her own bike too, till she sold it last year, least I managed to teach one of them something, I just dispair with the other, but we wont go in to that!

She walsed through, saying, ah youve broke it. I had a load of bits that wouldnt go back together. I said come on then smart bottom...

She picked the bits up, looked at them, 2 minutes later, there you go, and walked out!

She did service her own bike too, till she sold it last year, least I managed to teach one of them something, I just dispair with the other, but we wont go in to that!

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

Other daughter?

addjunkie

Member

- Messages

- 14,614

- Location

- Northumberland. Reet oot in the sticks

Son....lets just say a complete muppet and leave it at that!Other daughter?

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

Okie dokie.

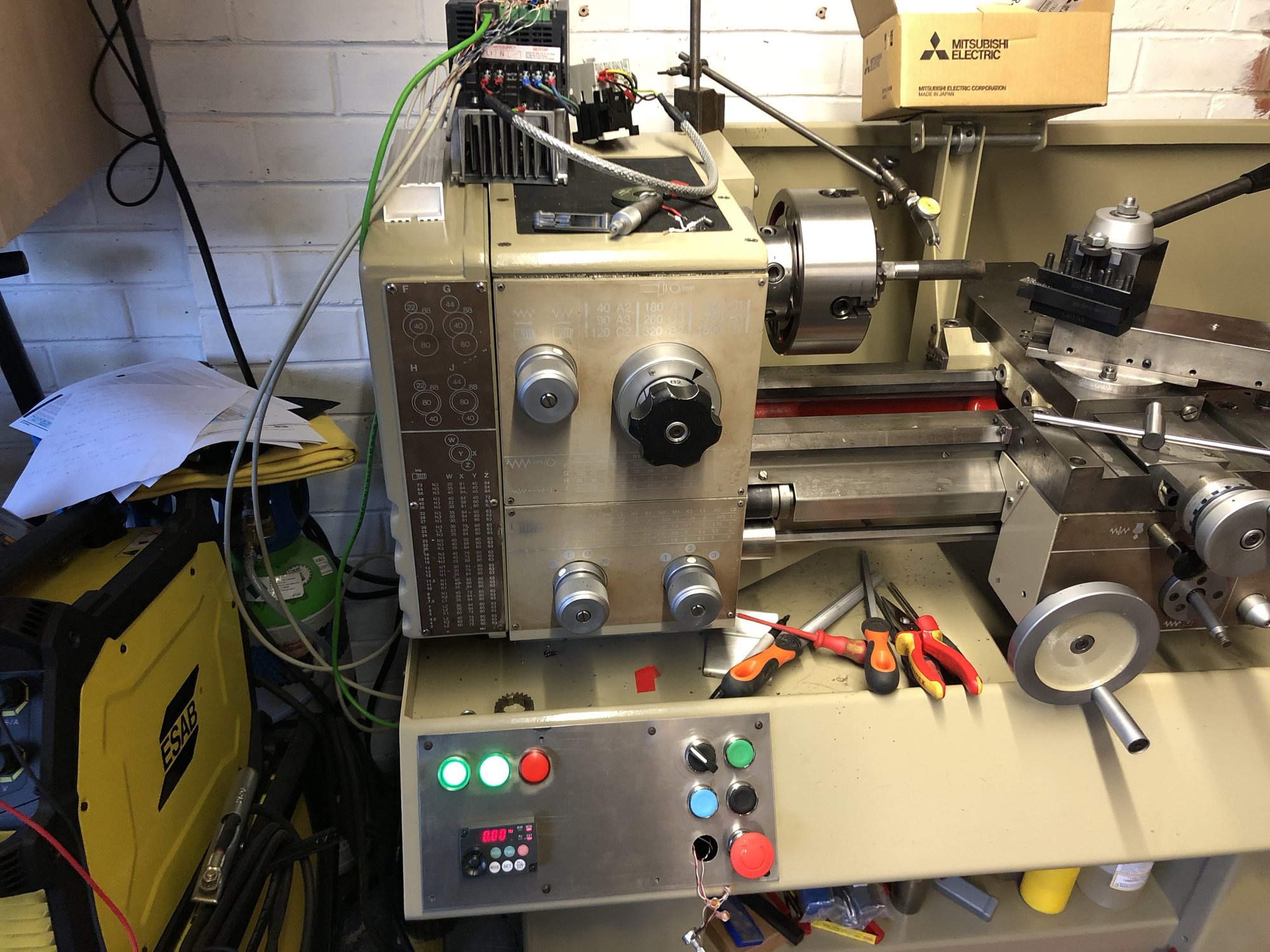

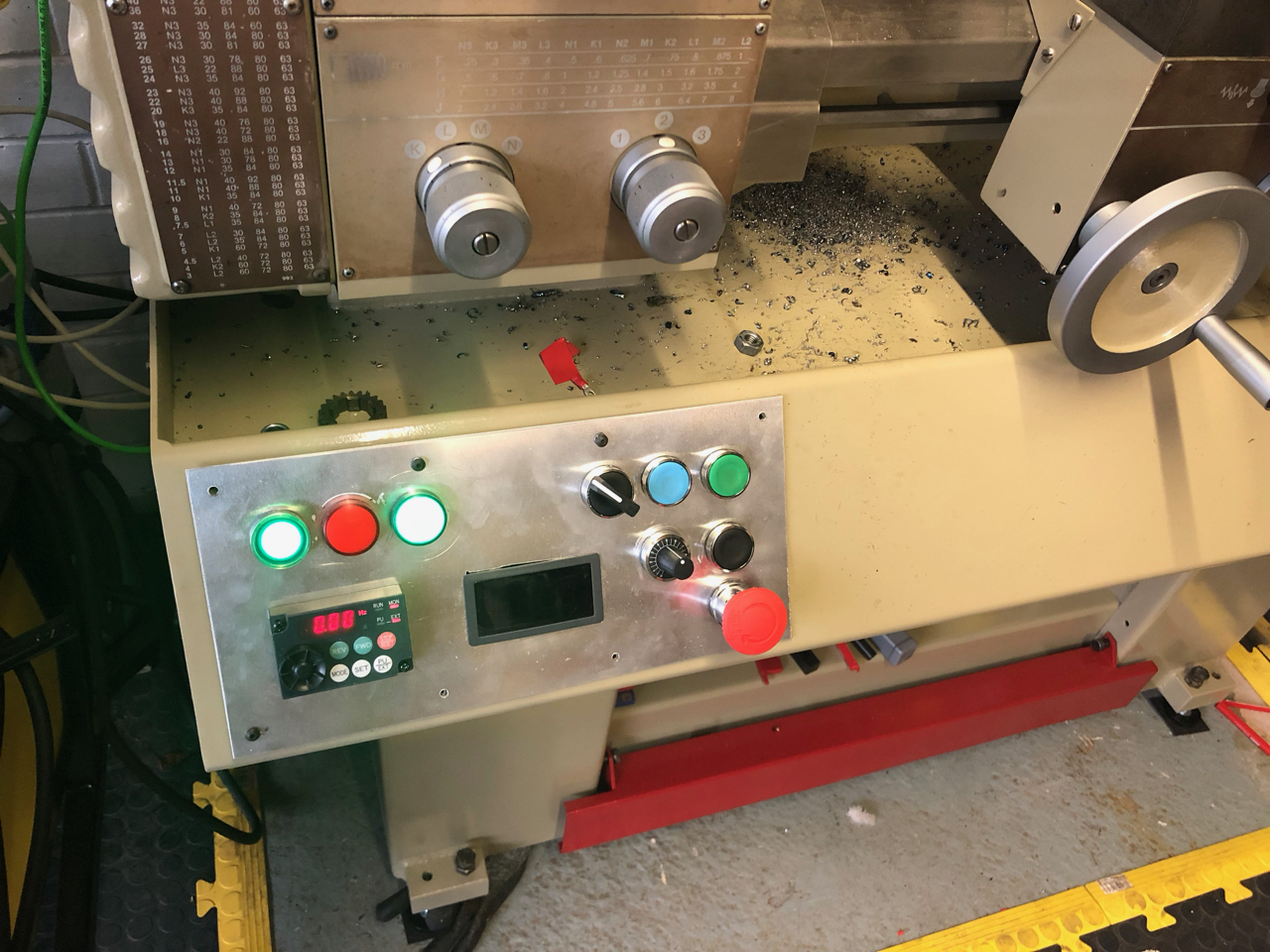

Braking resistor plumbed in this evening and contactor arrangement added so I now have power on/off via the panel (top left button). This button lights from the contactor output feed to indicate the VFD and accessories (DRO,Cooolant pump etc) are getting power. The brake resistor has added significant oomph to the brake performance, its a chunky thing and can be seen to the left of the VFD which I may mount externally on the enclosure with a protective cover. Next job look at the potentiometer mounting and then the spindle Tacho.

Note there will be an isolation switch on the Enclosure.

Note there will be an isolation switch on the Enclosure.

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

Looking very good. I take it the RJ45 is for the vfd repeater panel?

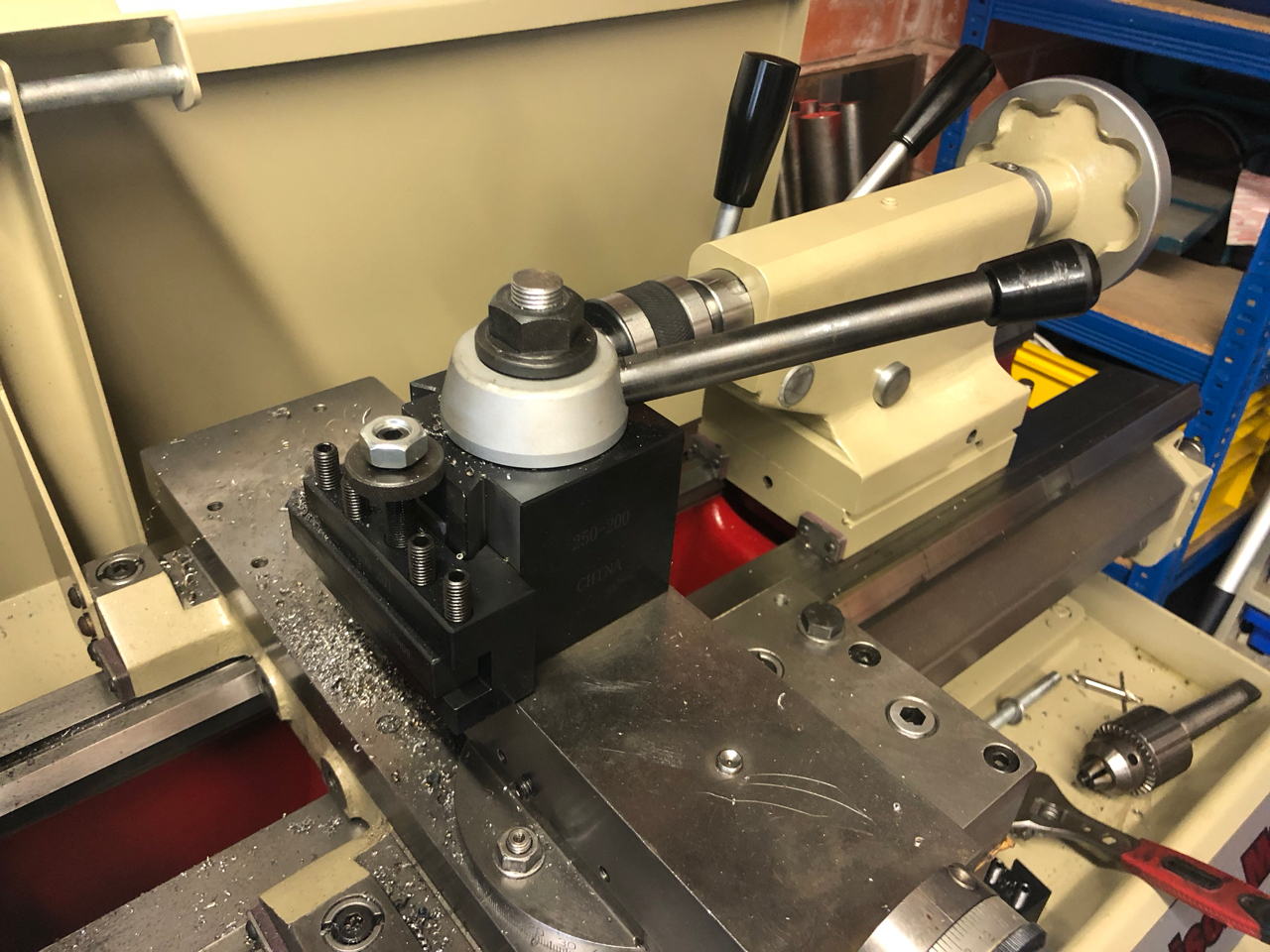

Not had much time this past week with work and family stuff, grabbed an hour or so this afternoon. Turned a replacement shear pin for the screw drive which went surprisingly well and fit first time ! its the most intricate thing I've done so far. Then as i'm back up and running screw cutting I turned a Tool Post mounting shaft from 20mm bar, simple design with M10 screw on one end to go into the lathe, a 16mm shaft and then a m16 thread for the hold down nut on top. It worked first time  Much sturdier now but will brave turning the base of the tool holder to fit the recess once i have a bit more experience .

Much sturdier now but will brave turning the base of the tool holder to fit the recess once i have a bit more experience .

I also cut out control panel 2.0 which has changes to the button layout to accommodate the Tacho screen (excuse the dodgy cutting) and also turned a 6mm extension for the Potentiometer shaft and got that fitting to the panel. The Pot has a centre detent which is calibrated to the standard running rate and then I've calibrated it to give +/- 25% speed either way. Once the Tacho is running ill recalibrate it to allow RPM shifts up and down too the next gear ratio.

new tool holding mount:

control panel v2.0

Much sturdier now but will brave turning the base of the tool holder to fit the recess once i have a bit more experience .

Much sturdier now but will brave turning the base of the tool holder to fit the recess once i have a bit more experience .I also cut out control panel 2.0 which has changes to the button layout to accommodate the Tacho screen (excuse the dodgy cutting) and also turned a 6mm extension for the Potentiometer shaft and got that fitting to the panel. The Pot has a centre detent which is calibrated to the standard running rate and then I've calibrated it to give +/- 25% speed either way. Once the Tacho is running ill recalibrate it to allow RPM shifts up and down too the next gear ratio.

new tool holding mount:

control panel v2.0

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

Really nice work. Great to see you making progress.

Yep its on centre although the nuts loose in the pic as I was playing. It has to be pretty much rock bottom to be dead on centre. This is why I’m not worried about taking 5mm or so off the bottom of the tool holder to fit in the recess.

mylesdw

Member

- Messages

- 797

I could do with some advice on Tool post fixing.

At the moment I have my QCTP temporarily clamped to the lathe with a m10 fence post bolt. The tool posts internal shaft bore is 16mm so theres slop and it can move around when under load, I need to make something proper. Looking at the Topslide there is a recess and I'm considering machining the bottom of the tool post in the 4 jaw chuck to create a matching fitting for this recess and then making a M10-m16 post holding bolt with clamping handle. The question is, is that a little OT and just a proper bolt is fine or is it what I am supposed to be doing? I'd be interested in how other Harrison M series owners mount a QCTP on their lathe.

Pic to show what I mean...

View attachment 152768

This cross slide looks remarkably similar to the one on my Colchester and there should be a thick washer that sits in that counterbore with a similar cut-out on the underside of the tool-post. When I fitted a QCTP recently I had to get the underside counter-bored and at the same time I had the cross slide drilled and re-tapped to take the mounting bolt that came with the new tool-post.