- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Eagle Mk3 surface grinder rebuild

- Thread starter Pete.

- Start date

Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

I'll have to check mine and see if they changed the setup on later models. If not then I guess I've got another project to get some oil into my ones ways.

If you do then make sure you stop a little shorter than I did so the cross-drill hole goes into that vertical rib, then you won't break through

ronan

Member

- Messages

- 11,382

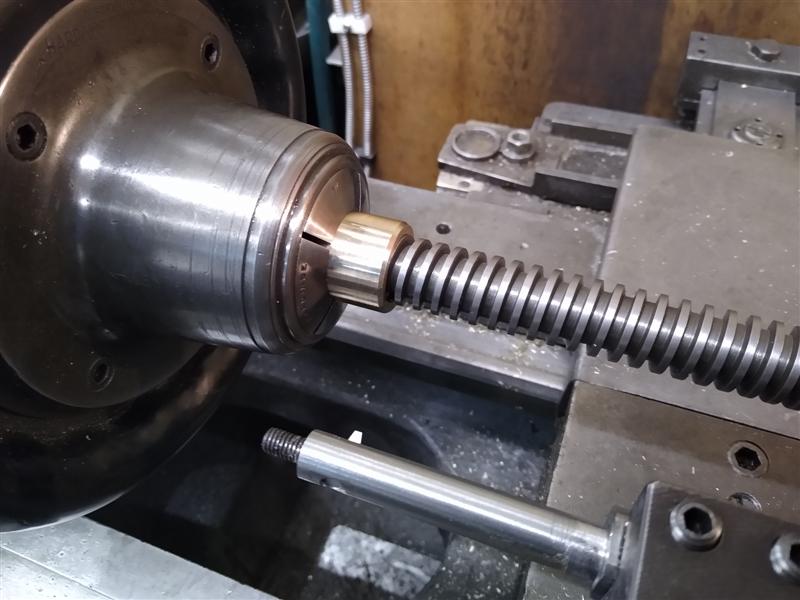

Z axis nut is all bored and threaded.

View attachment 206895

I had to knock up a quick & dirty boring holder for the insert. It wasn't great but it did the job and held up fine.

View attachment 206894

That's nearly it for the screw I have to turn the plain end down to .750", make a woodruff cutter to cut the key and then drill & tap the end for the securing bolt. I might just cut a straight keyway in it I don't see what harm it would do.

Well done. On the J&S 540 i need to replace my cross feed screw and nut. Popes who stock the parts have them...........for nearly £600 ! Can i ask where you bought the acme inserts ?

Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

I bought the inserts from eBay, have 8 and 10tpi LH. I could let you havean insert if you need one Ronan though I'm unsure if it'll so down the bore of the nut.

Your machine is an absolute sumbitch to do the cross slide nut on by the way. I had one that was badly worn and the nut & screw had been carrying the cross table weight.

BTW You could look at this list for your thread size see if it's listed. The platform nuts are a lot cheaper than you're quoted.

https://www.mcmaster.com/acme-nuts

Your machine is an absolute sumbitch to do the cross slide nut on by the way. I had one that was badly worn and the nut & screw had been carrying the cross table weight.

BTW You could look at this list for your thread size see if it's listed. The platform nuts are a lot cheaper than you're quoted.

https://www.mcmaster.com/acme-nuts

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,540

- Location

- The Shed of Danger, surrey, England

I bought the inserts from eBay, have 8 and 10tpi LH. I could let you havean insert if you need one Ronan though I'm unsure if it'll so down the bore of the nut.

Your machine is an absolute sumbitch to do the cross slide nut on by the way. I had one that was badly worn and the nut & screw had been carrying the cross table weight.

BTW You could look at this list for your thread size see if it's listed. The platform nuts are a lot cheaper than you're quoted.

https://www.mcmaster.com/acme-nuts

Thanks for the link, Pete - might have saved me screwcutting a LH 8 tpi internal Acme in bronze... or two if I want an anti-backlash nut? Cheaper than buying a tap, too...

Dave H. (the other one)

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,540

- Location

- The Shed of Danger, surrey, England

RDG tools have a large selection of Acme taps. Prices aren’t daft either. Use it sell it on.

I've been watching them, 5/8 8tpi left-hand have been permanently out of stock since I started looking 4 years ago... Must be popular?

Dave H. (the other one)

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,986

- Location

- East Yorkshire

I've been watching them, 5/8 8tpi left-hand have been permanently out of stock since I started looking 4 years ago... Must be popular?

Dave H. (the other one)

Come to think of it when I needed a one for my m300 they had no stock. So I used 1605 ball screw instead.

pressbrake1

Member

- Messages

- 5,776

- Location

- Essex

They’re impressively low qualityI've been watching them, 5/8 8tpi left-hand have been permanently out of stock since I started looking 4 years ago... Must be popular?

Dave H. (the other one)

mtt.tr

Member

- Messages

- 8,464

- Location

- Essex/Suffolk border

They’re impressively low quality

Rather just single point turn one. Actually that is exactly what i do!

ronan

Member

- Messages

- 11,382

They’re impressively low quality

Like a lot of rdg's products.

pressbrake1

Member

- Messages

- 5,776

- Location

- Essex

Rdg , a more expensive lower quality version of bang goodLike a lot of rdg's products.

Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

Rather just single point turn one. Actually that is exactly what i do!

So do I but this isn't exactly a trivial exercise.

Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

Cross slide nut is all done. Turned out to be an easier job that I thought it would be.

I ground a cutting bit from an old 6mm carbide end mill and turned a piece of tough steel down for a boring bar.

Cut a small relief groove in the end of the nut, just as a visual guide as much as anything. Also checked I had clearance all along. I'd allowed 12 thou (0.3mm).

Happy with that I cut the thread in 5 thou passes.

The screw fits really nice and snug, turns smooth too.

Nut ready to go in the holder tomorrow.

I ground a cutting bit from an old 6mm carbide end mill and turned a piece of tough steel down for a boring bar.

Cut a small relief groove in the end of the nut, just as a visual guide as much as anything. Also checked I had clearance all along. I'd allowed 12 thou (0.3mm).

Happy with that I cut the thread in 5 thou passes.

The screw fits really nice and snug, turns smooth too.

Nut ready to go in the holder tomorrow.

Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

Thanks Richard  Not done much this week but I have got some progress.

Not done much this week but I have got some progress.

As I suspected would happen, scraping 12 thou off the bottom of the table and probably 4 or 5 from the top of the cross-slide has caused the table to ride on the gear and rack rather than the ways. Here you can see the gap both sides.

This might be the reason the machine was taken out of service because of course I only took that much off the ends, the middle was already that low.

I put feeler gauges under the table until they were lightly pinched both sides. I did this right opposite the traverse gear that was holding it up.

The fix was simple enough, I just machined 15 thou off the spacers for the rack. Effectively lifting the rack up off the gear.

Once I did this there was no more constant interference but there was a 'lumpiness' caused by some ham-fisted removal of the gear previously. The corners had been beat up a little by someone using too hard a drift. They had attempted to dress it with a file but not very successfully. I put the gear in my lathe and turned the corners off. After that the table travel was perfect.

Not done much this week but I have got some progress.

Not done much this week but I have got some progress. As I suspected would happen, scraping 12 thou off the bottom of the table and probably 4 or 5 from the top of the cross-slide has caused the table to ride on the gear and rack rather than the ways. Here you can see the gap both sides.

This might be the reason the machine was taken out of service because of course I only took that much off the ends, the middle was already that low.

I put feeler gauges under the table until they were lightly pinched both sides. I did this right opposite the traverse gear that was holding it up.

The fix was simple enough, I just machined 15 thou off the spacers for the rack. Effectively lifting the rack up off the gear.

Once I did this there was no more constant interference but there was a 'lumpiness' caused by some ham-fisted removal of the gear previously. The corners had been beat up a little by someone using too hard a drift. They had attempted to dress it with a file but not very successfully. I put the gear in my lathe and turned the corners off. After that the table travel was perfect.

Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

Did some painting today. I found that you cannot brush paint enamel over yellow filler primer because the enamel paint melts the primer and you get a sickly grey-yellow mix as a result

I also made some new felt oilers for the table. The old ones were rock hard and made a noise like a dropped dice. I only had 4mm thick felt so I had to cut two per well and spilt one in half. Thankfully they peeled apart easily.

Then my heart sank when I noticed this:

Yes, the bloody table is riding on the top of the gib slightly. There's a small lip just above the dovetail and I've used up all the clearance.So sometime this week the gib is going to have to come off so I can mill a few thou off the top (or I'll have to set up the fly cutter and cut the lip some more). Then I'll have to re-adjust the whole lot again. Oh well, onwards and upwards!

I also made some new felt oilers for the table. The old ones were rock hard and made a noise like a dropped dice. I only had 4mm thick felt so I had to cut two per well and spilt one in half. Thankfully they peeled apart easily.

Then my heart sank when I noticed this:

Yes, the bloody table is riding on the top of the gib slightly. There's a small lip just above the dovetail and I've used up all the clearance.So sometime this week the gib is going to have to come off so I can mill a few thou off the top (or I'll have to set up the fly cutter and cut the lip some more). Then I'll have to re-adjust the whole lot again. Oh well, onwards and upwards!