- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Eagle Mk3 surface grinder rebuild

- Thread starter Pete.

- Start date

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,986

- Location

- East Yorkshire

Usually the wheel mounts onto a separate hub, that has weights that can be slid round a circular Tee slot and locked

I know what you mean now

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,986

- Location

- East Yorkshire

Is that because it would usually be set up with one wheel?That's right, usually the wheel clamps in a hub which sits on a taper or keyed shaft. The Eagle has a 2-piece hub that's a more posh version of the plates on a bench grinder just clamped by the nut on the front.

Where as a tool cutter grinder would require different shaped wheels, different wheels on hubs would saving having to rebalance every time?

Laurie Tedcastle

Forum Supporter

- Messages

- 130

- Location

- NW Northants (UK)

@pete,

Unfortunately I'm not familiar with the Eagle and you haven't shown a photo

of the spindle and wheel and flange(s) separated off the machine.

Many articles and letters in magazines such as ME and MEW lament the poor

location of grinding wheels on bench grinders particularly when pressed metal

flanges are employed. In MEW there are articles about improving this and also

balancing said wheels.

I have 2 bench grinders and have made dedicated hubs for mounting the wheels

with provision for balancing. These wheels are normally fitted with plastic

bushes, so with these removed there is room for my dedicated hubs. I suspect

my machining capability is somewhat less than yours, but after balancing I can

stand a £1 coin on edge on the machine with it running. I need to sort out a

decent dressing mechanism.

8" grinding wheel with dedicated hub and balancing "ears". The ears are cut

from 1mm sheet steel and rotated to provide balance.

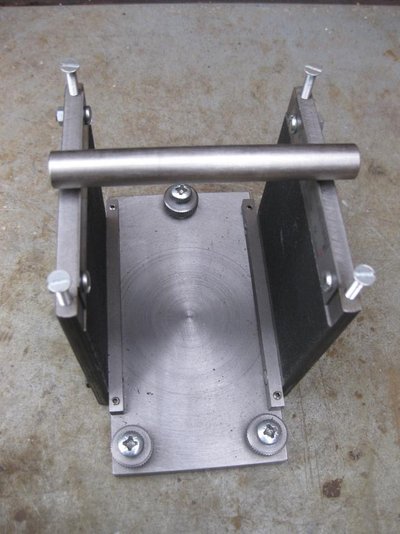

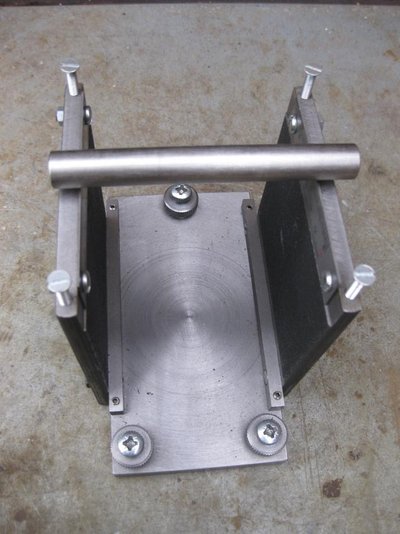

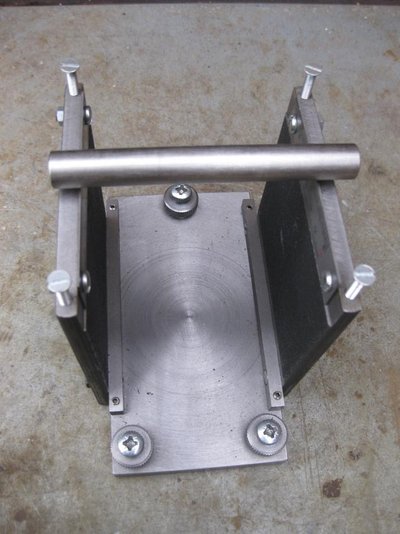

The simple balancing jig. The "knife edges" aren't quite - I cheated and cut

a cheap thin steel rule in half! Three screws for levelling & I use the level

from my M&W combination square set to set it up.

A wheel in position and reasonably balanced - well it hasn't rolled against the stops.

blob.jpg

Perhaps you could do something similar although you might need to find a wheel

with a larger bore.

Laurie

Unfortunately I'm not familiar with the Eagle and you haven't shown a photo

of the spindle and wheel and flange(s) separated off the machine.

Many articles and letters in magazines such as ME and MEW lament the poor

location of grinding wheels on bench grinders particularly when pressed metal

flanges are employed. In MEW there are articles about improving this and also

balancing said wheels.

I have 2 bench grinders and have made dedicated hubs for mounting the wheels

with provision for balancing. These wheels are normally fitted with plastic

bushes, so with these removed there is room for my dedicated hubs. I suspect

my machining capability is somewhat less than yours, but after balancing I can

stand a £1 coin on edge on the machine with it running. I need to sort out a

decent dressing mechanism.

8" grinding wheel with dedicated hub and balancing "ears". The ears are cut

from 1mm sheet steel and rotated to provide balance.

The simple balancing jig. The "knife edges" aren't quite - I cheated and cut

a cheap thin steel rule in half! Three screws for levelling & I use the level

from my M&W combination square set to set it up.

A wheel in position and reasonably balanced - well it hasn't rolled against the stops.

blob.jpg

Perhaps you could do something similar although you might need to find a wheel

with a larger bore.

Laurie

Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

Hi Laurie,

I've done similar with my bench grinder - not made balancing hubs like yours but I have made thicker plates with hubs to locate the wheels properly, and they do run a lot smoother than using those horrible pressed plates. I use surface grinder wheels on my bench grinders.

Thanks for showing your balancing jig. It's kinda similar design to the Jones and Shimpan

I've done similar with my bench grinder - not made balancing hubs like yours but I have made thicker plates with hubs to locate the wheels properly, and they do run a lot smoother than using those horrible pressed plates. I use surface grinder wheels on my bench grinders.

Thanks for showing your balancing jig. It's kinda similar design to the Jones and Shimpan

Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

Well, I'm calling this done. I do have to fit a tall end guard and one day I'll get around to hooking up coolant but for the time being I'm very satisfied with how it's come out. I wheeled it outside for some daylight pics.

Funny that Rob Cox and I both finished our rebuilds of the same machine on the same day!

Funny that Rob Cox and I both finished our rebuilds of the same machine on the same day!

Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

Parm

Respect The Sound System

- Messages

- 18,058

- Location

- Towcester

It sure is. It’s just too nice to get dirty in use

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,696

- Location

- North Kent, UK

That is the absolute Dogs! Spectacular work Pete!

- Messages

- 14,802

- Location

- UK

Nice job Pete, a credit to your patience and detail. Good that you've done a 'proper' refurb on it and not just sloshed 1/2 gallon of paint over it and sticking it on ebay like so many chancers do.