Pete.

Member

- Messages

- 15,030

- Location

- Kent, UK

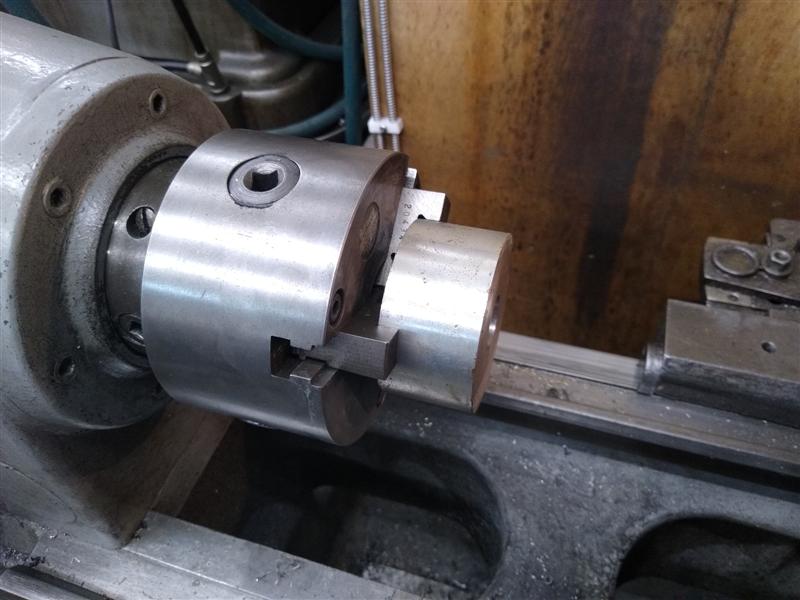

Got a good start today hoping to get loads done. Today's job is making new spindle pulleys. The only suitable motor I have is a single phase 1450rpm motor of about 1.5hp so I have to make speed-doubling pulleys.

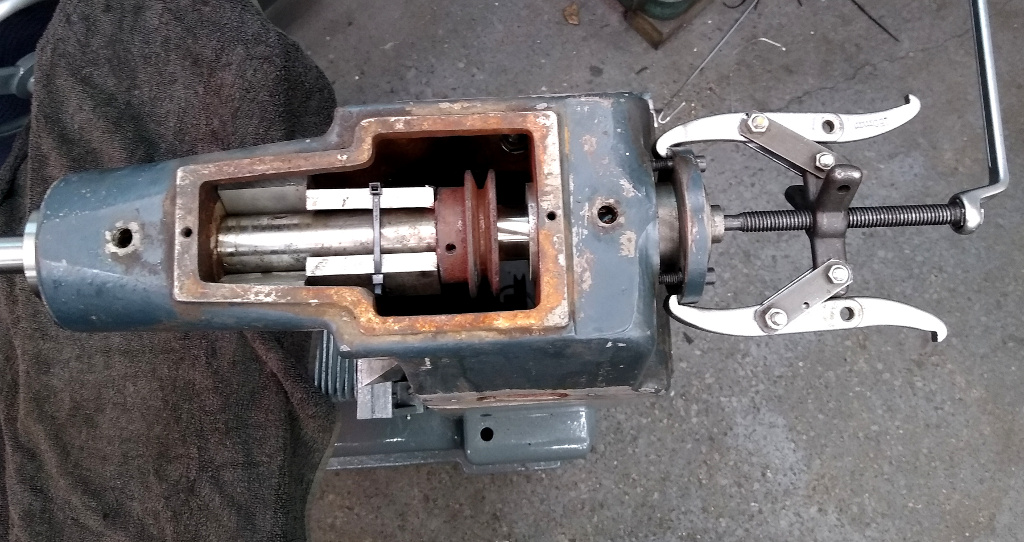

Here's the old pulley. It's very rusty and has bits of old belt stuck to it.

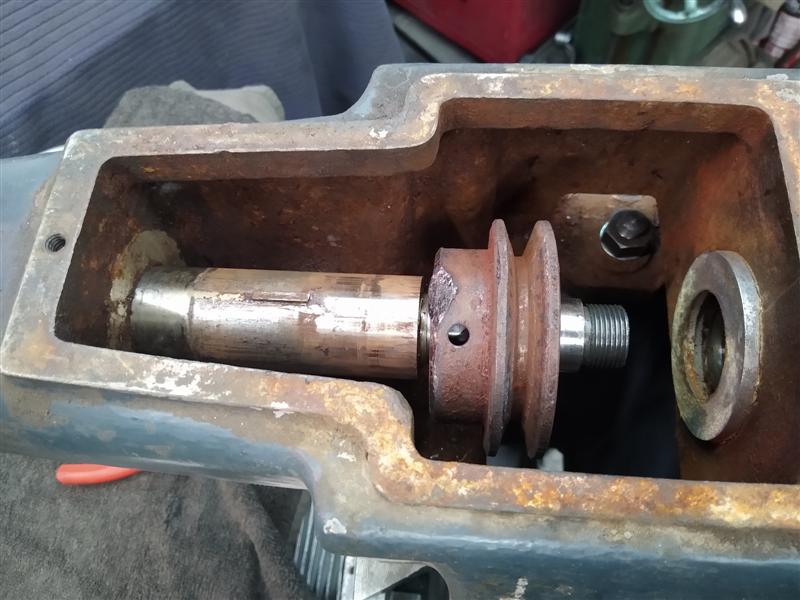

I had to heat it up to get the grub screw out and gave it a little tap around the periphery to see if it would move but no chance, so I had to rig up a puller. I took off the front bearing retainer and luckily it was the same bolt pattern as the rear cover. This meant I could put it on the rear end, fitted backwards so I didn't mess up the mounting face, and use it to pull against. I put a slug of scrap in the end so I didn't ruin the centre drilling for the shaft, in case I ever have to put that between centres sometime. Rigged up some blocks to stop the pulley against the front of the housing cavity and set up a 2-leg puller to push the spindle out through the pulley.

BTW you'll notice that the grinder head is not cleaned and painted. I wanted to get this work out of the way first and I want to have the bearings out of the head when I hit it with the sander and then paint.

The pulley was on there VERY tight. Even with heat the puller wouldn't move it so I had to resort to more neanderthal measures. I pulled it up as tight as I dare on the spanner and then hit the edge of the pulley to shock it along a tiny bit at a time.

About 15 minutes of that and the pulley is off.

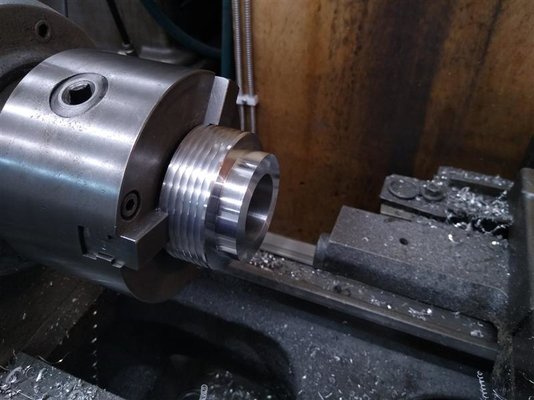

Now it's time to make new pulleys. Vee belts are fast disappearing from motor factors in favour of poly-vee belts so I'm making poly-vee pulleys. Here's the new belt.

And this is going to be the new pulley to suit it. The bottom pulley will be twice the diameter.

Here's the old pulley. It's very rusty and has bits of old belt stuck to it.

I had to heat it up to get the grub screw out and gave it a little tap around the periphery to see if it would move but no chance, so I had to rig up a puller. I took off the front bearing retainer and luckily it was the same bolt pattern as the rear cover. This meant I could put it on the rear end, fitted backwards so I didn't mess up the mounting face, and use it to pull against. I put a slug of scrap in the end so I didn't ruin the centre drilling for the shaft, in case I ever have to put that between centres sometime. Rigged up some blocks to stop the pulley against the front of the housing cavity and set up a 2-leg puller to push the spindle out through the pulley.

BTW you'll notice that the grinder head is not cleaned and painted. I wanted to get this work out of the way first and I want to have the bearings out of the head when I hit it with the sander and then paint.

The pulley was on there VERY tight. Even with heat the puller wouldn't move it so I had to resort to more neanderthal measures. I pulled it up as tight as I dare on the spanner and then hit the edge of the pulley to shock it along a tiny bit at a time.

About 15 minutes of that and the pulley is off.

Now it's time to make new pulleys. Vee belts are fast disappearing from motor factors in favour of poly-vee belts so I'm making poly-vee pulleys. Here's the new belt.

And this is going to be the new pulley to suit it. The bottom pulley will be twice the diameter.