- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Churchill Computurn 290 retrofit (again)

- Thread starter Hood

- Start date

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

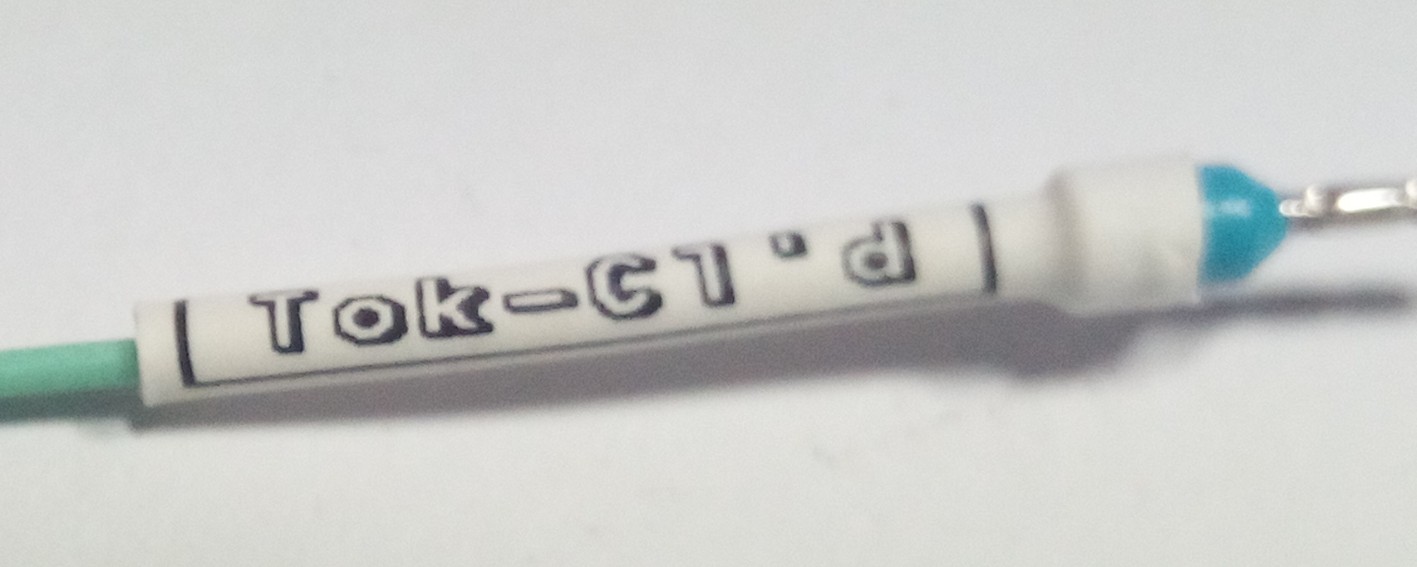

On the tape it is not too bad but the heat shrink is only 1.5m long (costs £25) and each one you do you lose 25mm of heat shrink. If you remember you can do all the ones you need in one print just by adding a couple of spaces between each and that way it is only 1x 25mm wasted. Just learning the ins and outs of the machine but it is quite impressive, even different fonts and you can even have shaded test or outline or both, boxes around etc see below.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

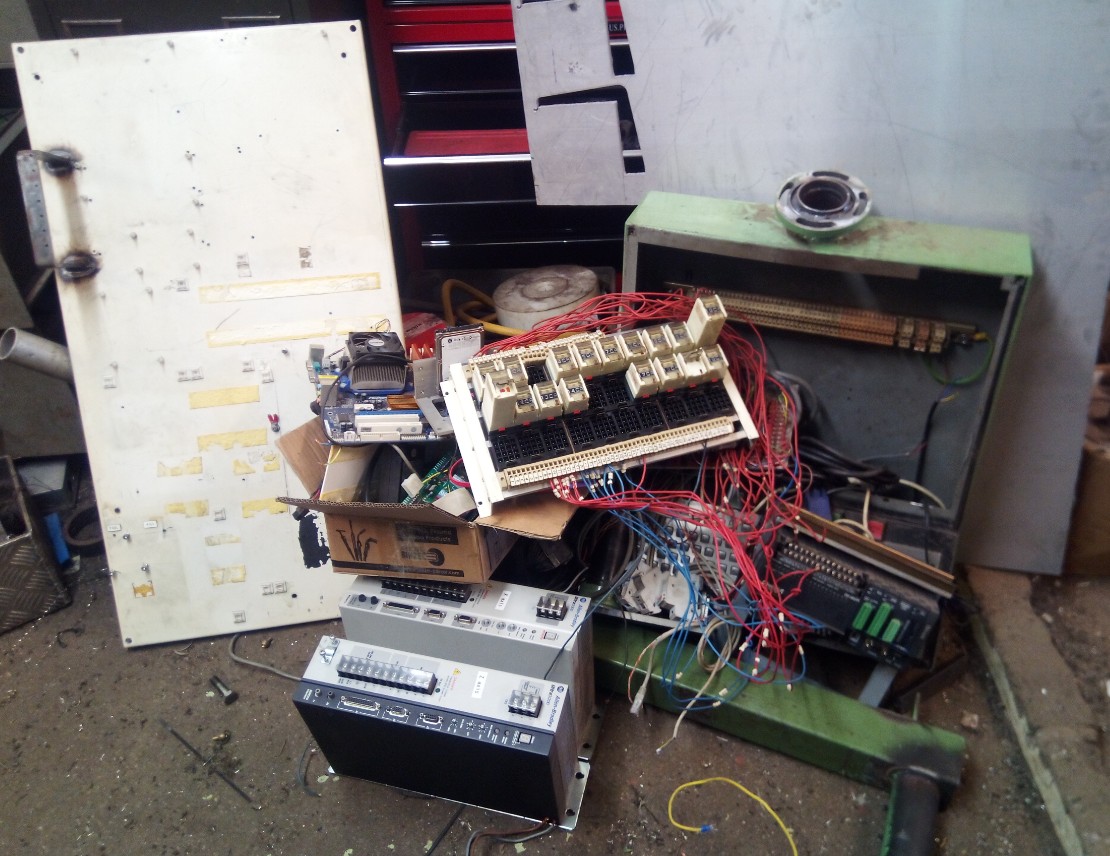

The lathe started playing up badly the other day so I decided I had had enough and it was time to start ripping stuff out even though I don't really have the time at the moment.

Ended up with a pile of components.

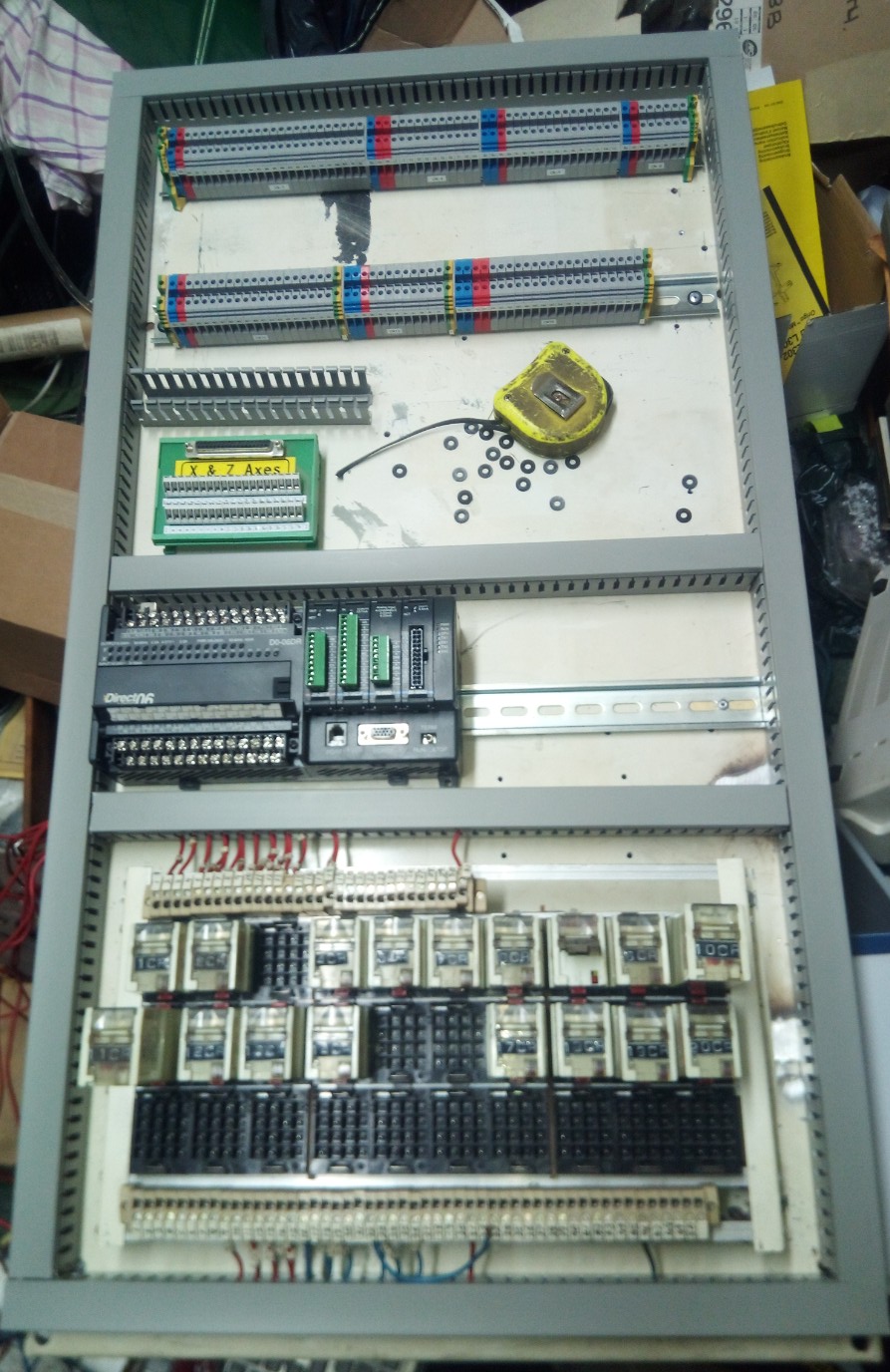

I brought the base board home with me and have spent the evening cleaning all the sticky pads off of it and then I started putting the trunking, relays, PLC and connectors on but I hadn't brought enough of the trunking home so couldn't get it finished so that will be a job for another day.

Ended up with a pile of components.

I brought the base board home with me and have spent the evening cleaning all the sticky pads off of it and then I started putting the trunking, relays, PLC and connectors on but I hadn't brought enough of the trunking home so couldn't get it finished so that will be a job for another day.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

You need to use heatshrink that is in a cassette which contains a ribbon which I presume is required for the printing, so if you could load a cassette with standard heat shrink it would probably work. Where you would get the ribbon however I have no idea and loading a cassette looks like it would be fiddly. The compatible one I am using at the moment seems fine and is 1/3 the price.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

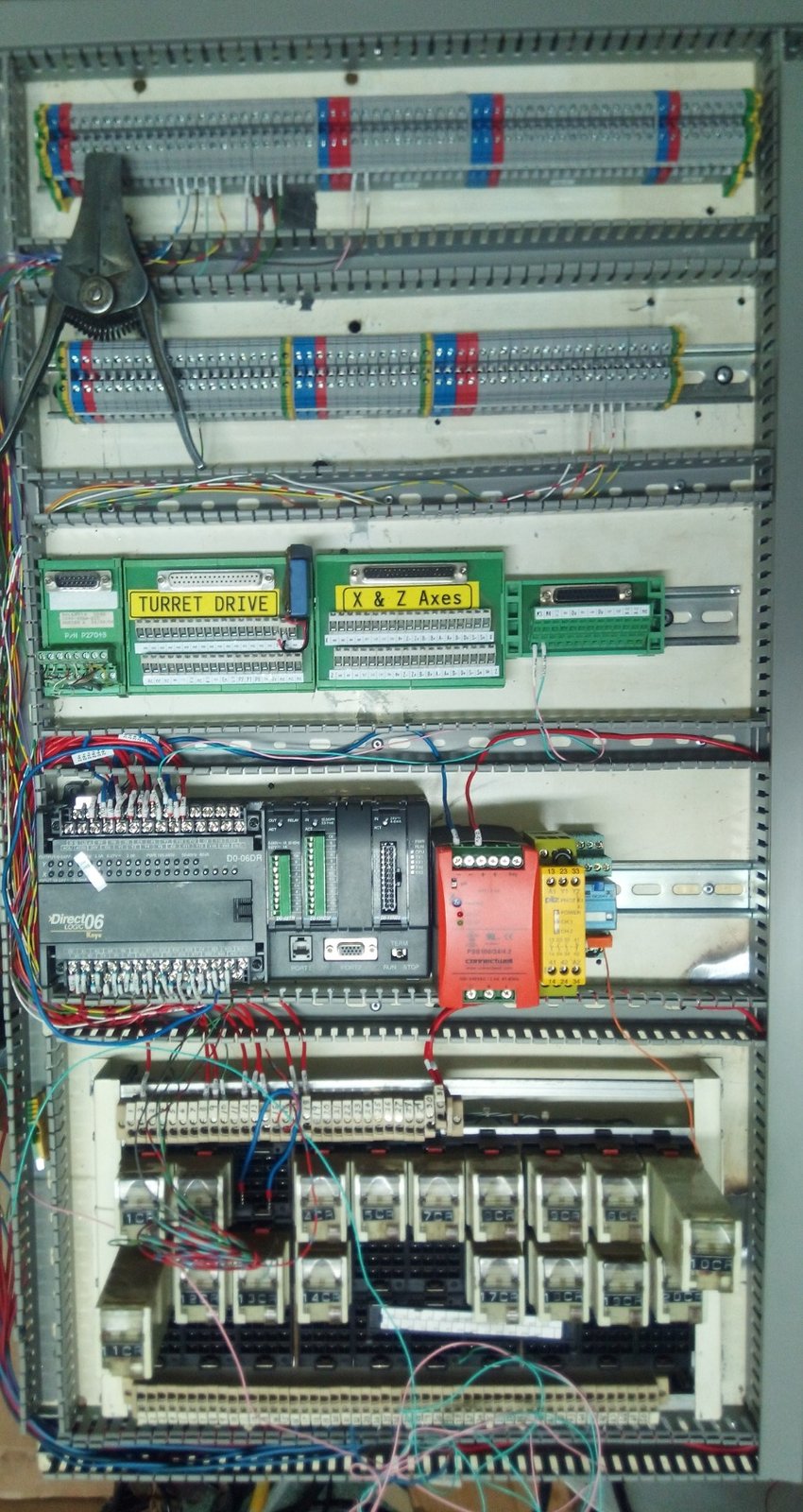

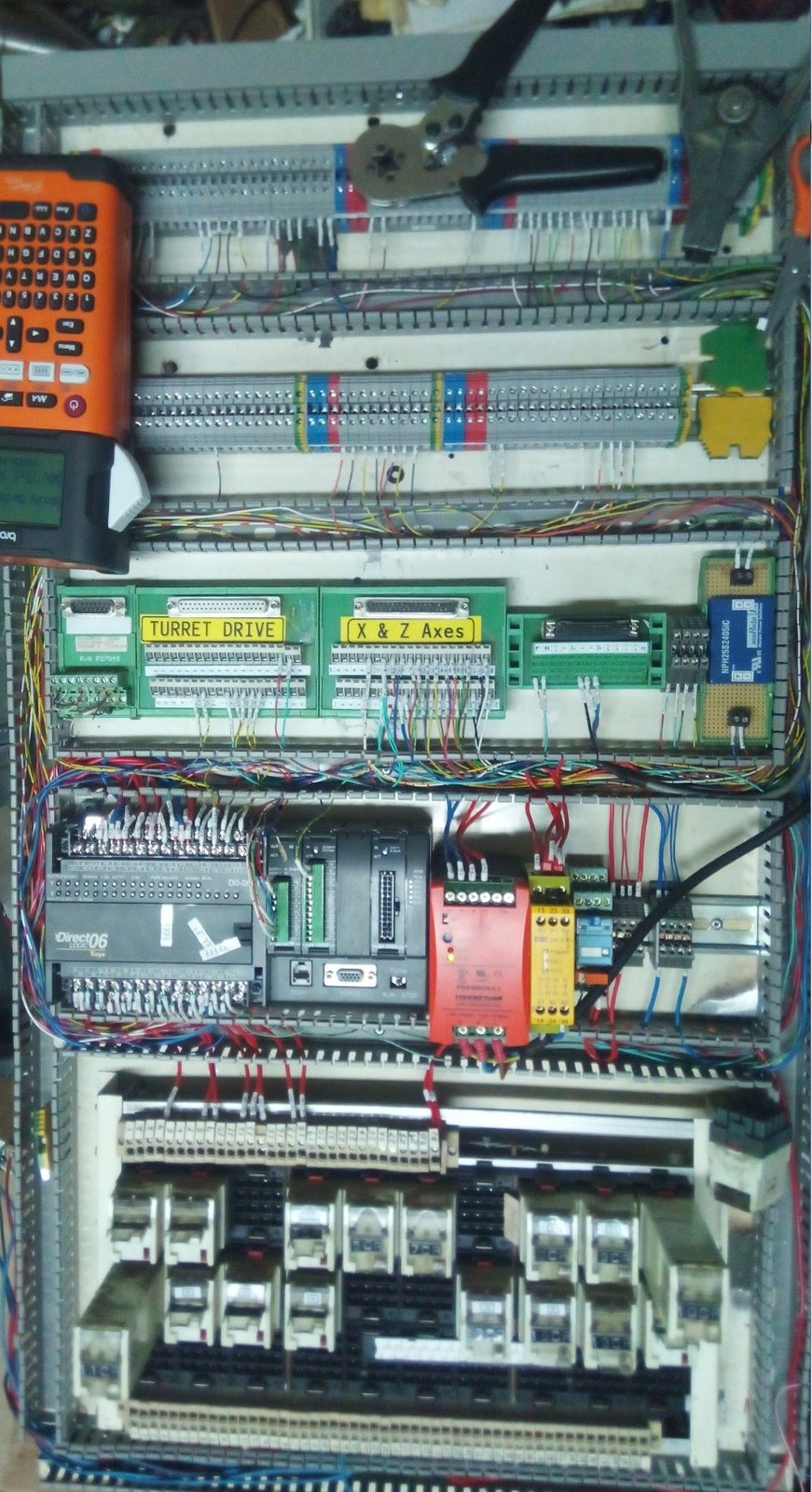

Getting some of the wiring done, still a bit to go before the panel is ready to fit back in so I can wire up the CNC controls wiring but hopefully it will be ready soon. I can then move on to the other panel which will have the mains, contactors, drives etc.

Oh and the trunking is all straight, just the camera makes it look squint, honest

Oh and the trunking is all straight, just the camera makes it look squint, honest

Very neat, a lovely job.

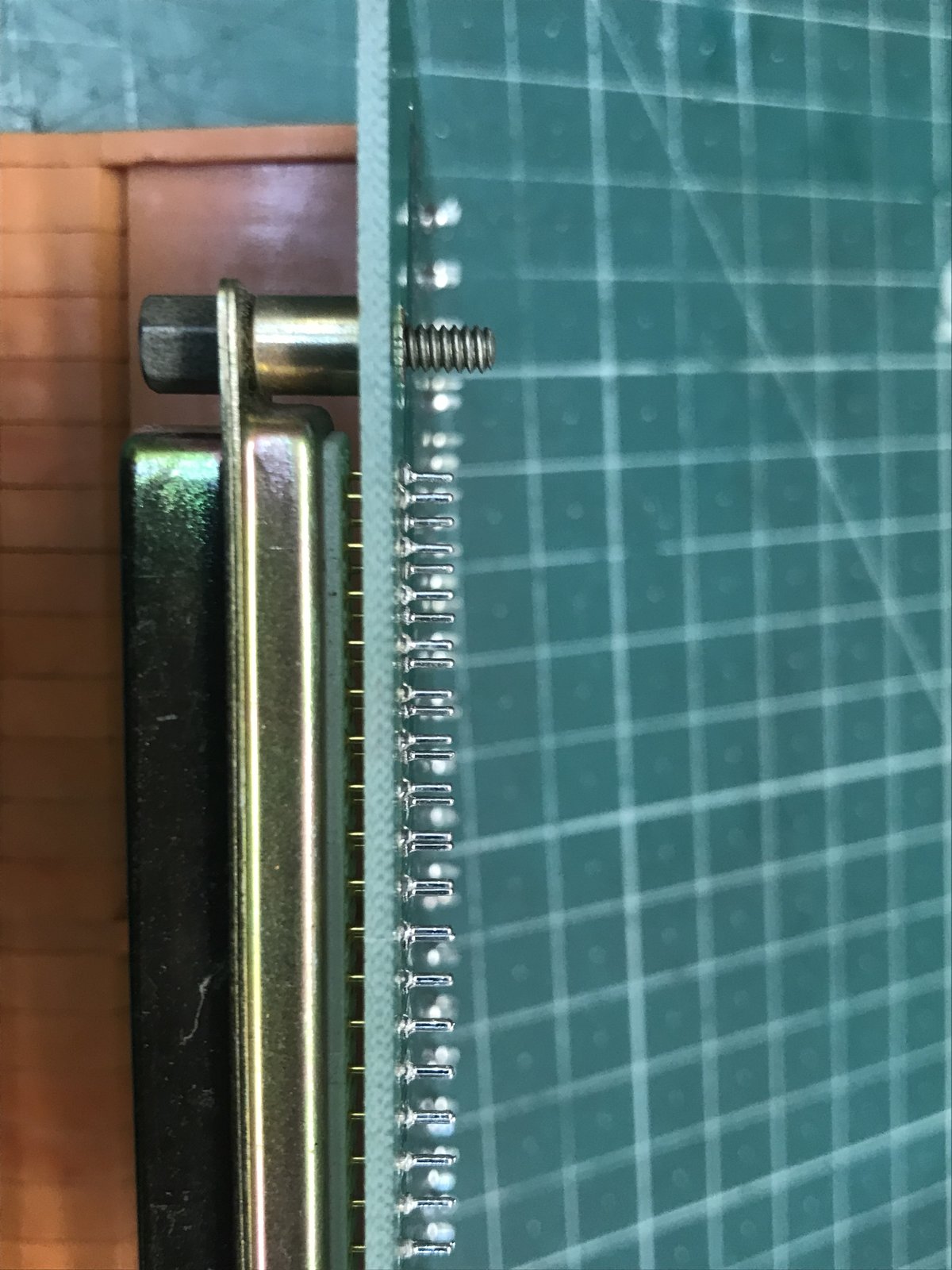

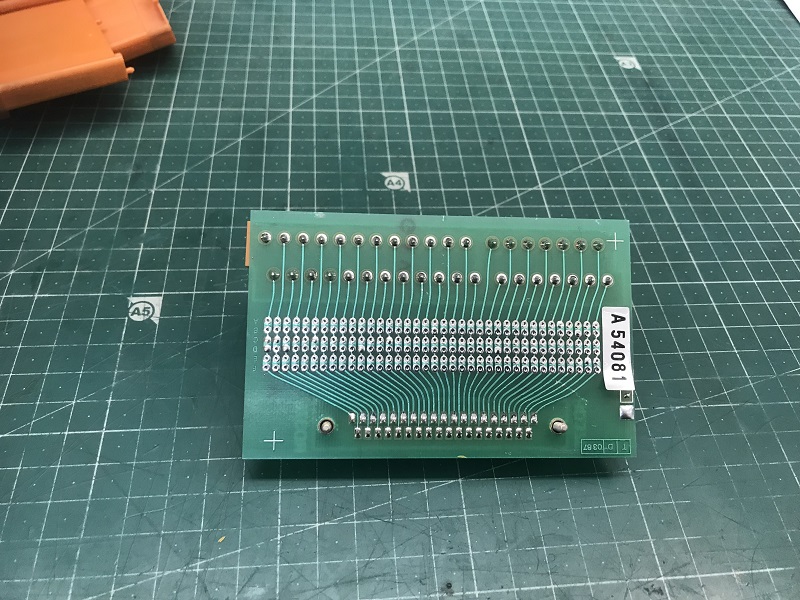

Beware of those 37 pin D Sub to terminal blocks if they are second hand. On my Beaver I've been having intermittent problems eventually traced to one of those with loads of dry joints. I spent an entire day, unwiring, labelling and re-soldering all five of them, one block had all 37 pins in a bad state , with others with just a few pins. On the bad one, each pin had a solder 'skirt' about 0.5 mm off the board! Check them !

Beware of those 37 pin D Sub to terminal blocks if they are second hand. On my Beaver I've been having intermittent problems eventually traced to one of those with loads of dry joints. I spent an entire day, unwiring, labelling and re-soldering all five of them, one block had all 37 pins in a bad state , with others with just a few pins. On the bad one, each pin had a solder 'skirt' about 0.5 mm off the board! Check them !

This might be the way to go on the thin wires, heat shrink it onto the bootlace ferrule end and that will stop it slipping. Below is on 0.9mm OD wire.

View attachment 169591

excellent, simple solution

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Mine are fine from the looks of them, can't recall if I bought them new or not as I have had them for a good while.Very neat, a lovely job.

Beware of those 37 pin D Sub to terminal blocks if they are second hand. On my Beaver I've been having intermittent problems eventually traced to one of those with loads of dry joints. I spent an entire day, unwiring, labelling and re-soldering all five of them, one block had all 37 pins in a bad state , with others with just a few pins. On the bad one, each pin had a solder 'skirt' about 0.5 mm off the board! Check them !

View attachment 172147

View attachment 172156

View attachment 172148

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

It does a good job and will help in the future if I have to go in there to alter anything but it is quite expensive as you only get 1.5m of shrink on a cassette and it doesn't go far especially with the waste on each print. I have learned now to do them all in batches with 3 spaces between each one and that means I only lose 1 length of 25mm tube at the start instead of 1 for each.excellent, simple solution

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

A load more wires connected, still a load more to go and I will need to get more heatshrink, have gone through 3 cassettes already and am on the last one.

I should have replaced the lower relays with Finder type as is next to the PNOZ safety relay, would have saved a load of space as half of them are not being reused, at least I will have spares I suppose.

I should have replaced the lower relays with Finder type as is next to the PNOZ safety relay, would have saved a load of space as half of them are not being reused, at least I will have spares I suppose.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Bit of progress this evening.

I had found that the control was set just a bit too high. I wear varifocals and I was finding the height it was meant I had to tilt my head up so that I was looking through the lower section of the specs, this would make for a very sore neck with anything longer than a minute or two at the control.

I chopped the bracket I had made and welded in a vertical section so that I could drop the cabinet by 40mm and it has made all the difference.

I also got the wires routed to the electrical cabinet, it is a bit rough and I will possibly make some sort of conduit for it at some stage but for now it will do.

I started on the mains/drives section of the panel but forgot I hadn't ordered any din rail so I couldn't get the fuses and contactors fitted and thus the wiring will have to wait but at least I got the main breaker, the 110v supply and the three servo drives and Yaskawa VFD fitted. I would have preferred to have all of the drives and VFD on the one level but the air gap required around the VFD especially meant that there was not enough room so I had to fit the turrets servo drive above the axis ones.

I also got the other panel fitted into the cabinet and most of the wiring sorted out into what will be getting used and what wont be.

I had found that the control was set just a bit too high. I wear varifocals and I was finding the height it was meant I had to tilt my head up so that I was looking through the lower section of the specs, this would make for a very sore neck with anything longer than a minute or two at the control.

I chopped the bracket I had made and welded in a vertical section so that I could drop the cabinet by 40mm and it has made all the difference.

I also got the wires routed to the electrical cabinet, it is a bit rough and I will possibly make some sort of conduit for it at some stage but for now it will do.

I started on the mains/drives section of the panel but forgot I hadn't ordered any din rail so I couldn't get the fuses and contactors fitted and thus the wiring will have to wait but at least I got the main breaker, the 110v supply and the three servo drives and Yaskawa VFD fitted. I would have preferred to have all of the drives and VFD on the one level but the air gap required around the VFD especially meant that there was not enough room so I had to fit the turrets servo drive above the axis ones.

I also got the other panel fitted into the cabinet and most of the wiring sorted out into what will be getting used and what wont be.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Quite a bit of progress today. Just home and probably still would have been there if my LED torch hadn't run out of battery.

Quick vid of the control switching on via the proper switch and the coolant and inhibit switch working. Pic at the end shows the progress with the wiring, still a fair bit to go but I am on the home straight. The setting up of the controls parameters and the servo drives I/O etc will be next after the wiring is complete.

Quick vid of the control switching on via the proper switch and the coolant and inhibit switch working. Pic at the end shows the progress with the wiring, still a fair bit to go but I am on the home straight. The setting up of the controls parameters and the servo drives I/O etc will be next after the wiring is complete.