Hood

I am obsessed.

- Messages

- 17,715

- Location

- Carnoustie, Scotland

I thought I would put up a post to document the progress of a planned retrofit of my CNC lathe.

It is a Churchill Computurn CNC lathe that I got, probably about 2006. It was very little used as it had come from Hull Uni and as far as I can make out was only used in a study for testing carbide and CBN inserts.

A pic of it on the trailer when I got it, it is a fairly big lathe weighing in about 3 tonne.

And a pic of it in my workshop when it was less cluttered with machines.

I retrofitted it with Mach3, originally via the parallel port but then the USB SmoothStepper and latterly the Ethernet version. It has done me proud and worked well and I have added and adapted many things on it such as making a turret, fitting a hydraulic chuck and chucking cylinder etc.

The Smoothstepper , I think, has recently been giving me issues, I think it is slowly dying so I decided I needed to upgrade. I was going to be going with a CSMIOIP-A controller like I have on the Chiron FZ12S but for some strange reason I decided to go for a stand alone Chinese controller from SZGH in China, think it may actually be the same as the Newker controllers and it is probably them that make it.

I have had the controller for quite a few weeks now and have it set up in the work room at home or the junk room as my other half calls it

I made a stand to set it up in so that I could wire things such as limits and generally mess around with it and get used to it.

I have also started on making a housing for it on the machine, my painting skills are dire but it will hopefully do the job.

As I said I have been messing around with the controller and it has quite a nice feature that I think will be handy for doing a first run of new code. You can put it into handwheel mode and run the code from turning the MPG, it means you could use the MPG mode to make sure the tool is going to where it is meant to be and then you can change back to computer control whenever you want. Quick video of it below.

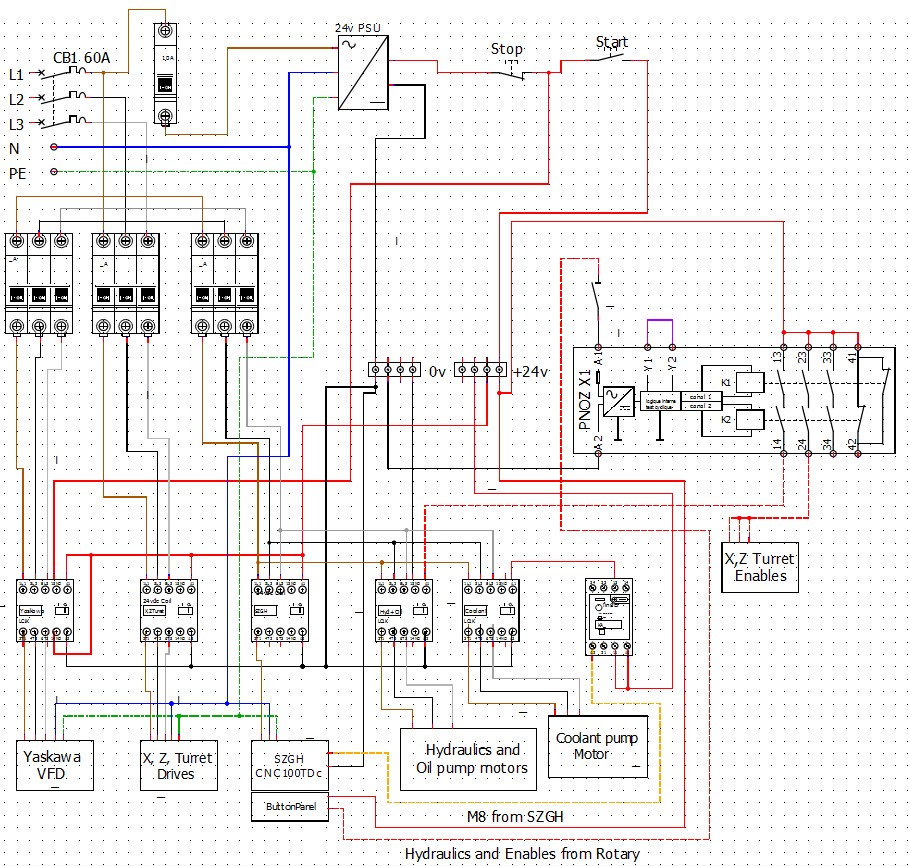

I have just finished working out the power side of the wiring, pic below.

The hydraulic pump and oil pump I am going to control from the panel inhibit switch, it will allow me to shut off the noise from these motors when I am not running the machine and with doing it via that switch there is no chance of the machine running and me forgetting to turn them back on. I wasn't sure how I would manage that as the switch only had 2 NO contacts on it but I found out you can get double contact blocks to fit the switch so position 1 will now have 2 NO contacts, one to put the machine into normal run mode and the other going to the PILZ safety relay to energise the servo drive enables and also the Hydraulics and Oil pumps. The middle position has no contacts on it, that puts it into inhibit axis mode which means the axes can't be moved and it will also drop out the PILZ relay and thus the hydraulics and Oil will switch off and the servo drives enables will be taken away. The third position of the switch also stops the spindle from being used but I will probably never have it in that mode anyway.

Well that is enough for now, not sure when I will actually start on the retrofit as I still have a few things to work out and I will also be busy on a new Cheetah Cat that should be arriving next week and that will take up most of my time.

It is a Churchill Computurn CNC lathe that I got, probably about 2006. It was very little used as it had come from Hull Uni and as far as I can make out was only used in a study for testing carbide and CBN inserts.

A pic of it on the trailer when I got it, it is a fairly big lathe weighing in about 3 tonne.

And a pic of it in my workshop when it was less cluttered with machines.

I retrofitted it with Mach3, originally via the parallel port but then the USB SmoothStepper and latterly the Ethernet version. It has done me proud and worked well and I have added and adapted many things on it such as making a turret, fitting a hydraulic chuck and chucking cylinder etc.

The Smoothstepper , I think, has recently been giving me issues, I think it is slowly dying so I decided I needed to upgrade. I was going to be going with a CSMIOIP-A controller like I have on the Chiron FZ12S but for some strange reason I decided to go for a stand alone Chinese controller from SZGH in China, think it may actually be the same as the Newker controllers and it is probably them that make it.

I have had the controller for quite a few weeks now and have it set up in the work room at home or the junk room as my other half calls it

I made a stand to set it up in so that I could wire things such as limits and generally mess around with it and get used to it.

I have also started on making a housing for it on the machine, my painting skills are dire but it will hopefully do the job.

As I said I have been messing around with the controller and it has quite a nice feature that I think will be handy for doing a first run of new code. You can put it into handwheel mode and run the code from turning the MPG, it means you could use the MPG mode to make sure the tool is going to where it is meant to be and then you can change back to computer control whenever you want. Quick video of it below.

I have just finished working out the power side of the wiring, pic below.

The hydraulic pump and oil pump I am going to control from the panel inhibit switch, it will allow me to shut off the noise from these motors when I am not running the machine and with doing it via that switch there is no chance of the machine running and me forgetting to turn them back on. I wasn't sure how I would manage that as the switch only had 2 NO contacts on it but I found out you can get double contact blocks to fit the switch so position 1 will now have 2 NO contacts, one to put the machine into normal run mode and the other going to the PILZ safety relay to energise the servo drive enables and also the Hydraulics and Oil pumps. The middle position has no contacts on it, that puts it into inhibit axis mode which means the axes can't be moved and it will also drop out the PILZ relay and thus the hydraulics and Oil will switch off and the servo drives enables will be taken away. The third position of the switch also stops the spindle from being used but I will probably never have it in that mode anyway.

Well that is enough for now, not sure when I will actually start on the retrofit as I still have a few things to work out and I will also be busy on a new Cheetah Cat that should be arriving next week and that will take up most of my time.

Last edited:

So big thanks go out to

So big thanks go out to