You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brew day!

- Thread starter Maker

- Start date

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

Tested the pumps, they work excellently on 12V but don't seem to like 5V, it was a rushed, dodgy test setup though. The listing said "Brushless", I had assumed that means the brushes aren't replaceable/mistranslated Chinese/barefaced lying, I'd be very surprised if they actually have BLDC motors and an ESC inside but that could explain it not liking lower voltage. Either way, the plan was always to make a PWM controller to save having to buy new variable power supplies. The listing claims 8.4 watts, I measured 1.7A at 12V so more like 20W. Doesn't really matter, just means the 1.2A H-bridge I wanted to use won't work. Don't need a full H-bridge anyway so no great loss, I'll find some MOSFETs

Last edited:

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

I got a PID and a couple of elements too. The 14" one is from Screwfix, the other is something my dad had kicking around, says 1984 on the box!  I noticed after buying it that you're not supposed to use a copper element in a stainless cylinder, I don't know if that means it'll break in five minutes or it'll just break prematurely if I'm using it day-in, day-out heating hot water in a house like it's designed for. I had been planning to put my temperature sensor in the thermowell the stat came out of but I think it'll probably read significantly higher than the actual average temperature in the vessel being so close to the element.

I noticed after buying it that you're not supposed to use a copper element in a stainless cylinder, I don't know if that means it'll break in five minutes or it'll just break prematurely if I'm using it day-in, day-out heating hot water in a house like it's designed for. I had been planning to put my temperature sensor in the thermowell the stat came out of but I think it'll probably read significantly higher than the actual average temperature in the vessel being so close to the element.

The listing for the PID claims it'll work with PT100 sensors but the wiring diagram shows resistive sensors connect to a terminal which isn't even on the thing, looks like that's getting returned. Having seen the manual these Chinese controllers come with, I'm temped to look for a second hand Eurotherm or similar, something with a bit more support, I don't have a clue how to set this one up.

Having seen the manual these Chinese controllers come with, I'm temped to look for a second hand Eurotherm or similar, something with a bit more support, I don't have a clue how to set this one up.

I noticed after buying it that you're not supposed to use a copper element in a stainless cylinder, I don't know if that means it'll break in five minutes or it'll just break prematurely if I'm using it day-in, day-out heating hot water in a house like it's designed for. I had been planning to put my temperature sensor in the thermowell the stat came out of but I think it'll probably read significantly higher than the actual average temperature in the vessel being so close to the element.

I noticed after buying it that you're not supposed to use a copper element in a stainless cylinder, I don't know if that means it'll break in five minutes or it'll just break prematurely if I'm using it day-in, day-out heating hot water in a house like it's designed for. I had been planning to put my temperature sensor in the thermowell the stat came out of but I think it'll probably read significantly higher than the actual average temperature in the vessel being so close to the element.

The listing for the PID claims it'll work with PT100 sensors but the wiring diagram shows resistive sensors connect to a terminal which isn't even on the thing, looks like that's getting returned.

Having seen the manual these Chinese controllers come with, I'm temped to look for a second hand Eurotherm or similar, something with a bit more support, I don't have a clue how to set this one up.

Having seen the manual these Chinese controllers come with, I'm temped to look for a second hand Eurotherm or similar, something with a bit more support, I don't have a clue how to set this one up.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

It is, from this listing.

brewdexta

The biggest tool in the box

- Messages

- 5,747

- Location

- UK

Here's the instructions, should be similar. One thing I noticed on mine was that the PT100 options did not appear on the PID unless the probe was connected.

Here's my thread on a brewing forum from 2012 when I first started playing with PIDs that may help.

Here's my thread on a brewing forum from 2012 when I first started playing with PIDs that may help.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

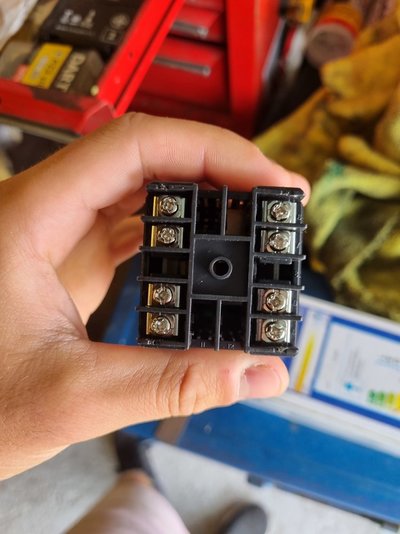

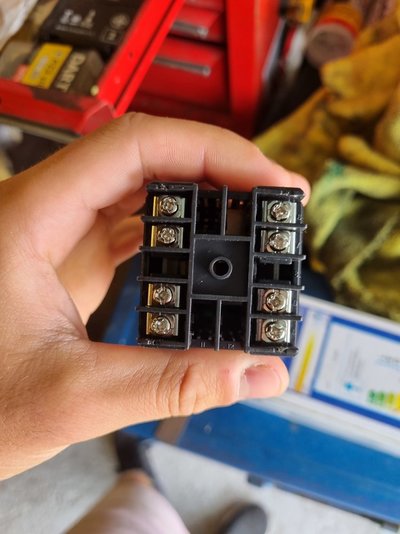

Cheers, I'll have a read through in a bit. Here's the problem with this controller, terminals 3 and 8 are missing, the listing shows all 10 though.

Do I need a PID for the kettle? I'd have thought not, it will maintain its own temperature at exactly boiling but nearly every brewing controller I've seen online they have one.

Do I need a PID for the kettle? I'd have thought not, it will maintain its own temperature at exactly boiling but nearly every brewing controller I've seen online they have one.

Bullet2012

Member

- Messages

- 5,225

- Location

- on average about 200 miles from the ISS.

I am still waiting for my bottles to arrive, I think makers online shop has conned me out of SWMBOs hard earned.

brewdexta

The biggest tool in the box

- Messages

- 5,747

- Location

- UK

I'll go and look at mine after lunchCheers, I'll have a read through in a bit. Here's the problem with this controller, terminals 3 and 8 are missing, the listing shows all 10 though.

View attachment 307036

View attachment 307037

Do I need a PID for the kettle? I'd have thought not, it will maintain its own temperature at exactly boiling but nearly every brewing controller I've seen online they have one.

I do have a PID on the copper, but just to read the temperature so I know when its approaching boiling so I can take the lid off. It boils quicker with the lid on but if you leave it on you end up with boiling wort everywhere, then it shorts out the elements so makes a bit of a mess....

Edit - I just remembered, I do have the PID controlling the elements via a SSR but set the target temp to 110c so it never kicks in. This is so I can use it on the hot liquor tank should that PID or SSR fail.

brewdexta

The biggest tool in the box

- Messages

- 5,747

- Location

- UK

Mine has all the terminals. Even if you didn't use the lead resistance compensation wire, i.e. a two wire PT100, you would still needs terminals 8 and 9 so your PID makes little sense to me. My Rex C100 was made by RKC instruments in Japan.

I did buy a spare PID and SSR a few months ago, from here. It came with all the terminals. It also was made by RKC, but now inevitably made in China.

I did buy a spare PID and SSR a few months ago, from here. It came with all the terminals. It also was made by RKC, but now inevitably made in China.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

I've got myself a capper now so I can distribute bottles without having to chase people up to get my swing tops back. Don't worry, I've got every intention of repaying you for the gloves.I am still waiting for my bottles to arrive, I think makers online shop has conned me out of SWMBOs hard earned.

Bullet2012

Member

- Messages

- 5,225

- Location

- on average about 200 miles from the ISS.

Ahh sorry wasn’t meaning that, I was completely jesting.I've got myself a capper now so I can distribute bottles without having to chase people up to get my swing tops back. Don't worry, I've got every intention of repaying you for the gloves.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

I know, but I was planning on sending you a couple of bottles anyway.Ahh sorry wasn’t meaning that, I was completely jesting.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

Just seen this video on a ready made system and at 10:40 they say the kettle PID controller is set for "percent power output" (So not PID at allEdit - I just remembered, I do have the PID controlling the elements via a SSR but set the target temp to 110c so it never kicks in. This is so I can use it on the hot liquor tank should that PID or SSR fail.

). I can't figure out if these C100 controllers have that mode but if not, it wouldn't be hard to do it with an Arduino, almost the exact same code and circuit the pumps are running on actually.

). I can't figure out if these C100 controllers have that mode but if not, it wouldn't be hard to do it with an Arduino, almost the exact same code and circuit the pumps are running on actually.Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

The first keg I cut open by butchering a hole in the top and then cutting from the inside right up to the wall so there'd be no rim. That was impractical, a lot of work and doesn't allow me to use a lid, I reckon that ones gonna be my HLT. I've just cut the second keg a lot more carefully, nice neat circle so the piece I cut out can have three tabs welded onto it and it'll drop back on top as a handy lid.

The hole is just shy of 13", I wasn't aiming for a specific size, just bigger than 12" so I can buy a standard false bottom and fit it in easily. This one's a bit grubbier inside than the first one too, I think it needs passivating? I'll wait till the welding's done for that.

I think I'm going to try a rotating racking arm in the boil kettle rather than some sort of screen or filter, I can use it as a whirlpool inlet and in theory gather all the hops and hot break in the middle, then turn it round and drain off nice clean wort. I'll still put a fitting right at the bottom for cleaning. This seems to be the done thing in commercial brewing but less common at this scale, maybe everyone who knows what they're doing knows this doesn't work.

I'm thinking about using coils from a beer cooler as a HERMS coil and immersion chiller too, loads on eBay less than 20 quid for a nice compact food safe heat exchanger coil, seems perfect.

The hole is just shy of 13", I wasn't aiming for a specific size, just bigger than 12" so I can buy a standard false bottom and fit it in easily. This one's a bit grubbier inside than the first one too, I think it needs passivating? I'll wait till the welding's done for that.

I think I'm going to try a rotating racking arm in the boil kettle rather than some sort of screen or filter, I can use it as a whirlpool inlet and in theory gather all the hops and hot break in the middle, then turn it round and drain off nice clean wort. I'll still put a fitting right at the bottom for cleaning. This seems to be the done thing in commercial brewing but less common at this scale, maybe everyone who knows what they're doing knows this doesn't work.

I'm thinking about using coils from a beer cooler as a HERMS coil and immersion chiller too, loads on eBay less than 20 quid for a nice compact food safe heat exchanger coil, seems perfect.

brewdexta

The biggest tool in the box

- Messages

- 5,747

- Location

- UK

I just wrapped copper pipe around a length of waste pipe to form the coil and put it into a 6 litre SS insulated soup/stew container and stuck an element through the bottom of the pot. There's loads of big SS catering pots for not much on flea bay, but most come from Germany or France.The first keg I cut open by butchering a hole in the top and then cutting from the inside right up to the wall so there'd be no rim. That was impractical, a lot of work and doesn't allow me to use a lid, I reckon that ones gonna be my HLT. I've just cut the second keg a lot more carefully, nice neat circle so the piece I cut out can have three tabs welded onto it and it'll drop back on top as a handy lid.

View attachment 307251

The hole is just shy of 13", I wasn't aiming for a specific size, just bigger than 12" so I can buy a standard false bottom and fit it in easily. This one's a bit grubbier inside than the first one too, I think it needs passivating? I'll wait till the welding's done for that.

I think I'm going to try a rotating racking arm in the boil kettle rather than some sort of screen or filter, I can use it as a whirlpool inlet and in theory gather all the hops and hot break in the middle, then turn it round and drain off nice clean wort. I'll still put a fitting right at the bottom for cleaning. This seems to be the done thing in commercial brewing but less common at this scale, maybe everyone who knows what they're doing knows this doesn't work.

I'm thinking about using coils from a beer cooler as a HERMS coil and immersion chiller too, loads on eBay less than 20 quid for a nice compact food safe heat exchanger coil, seems perfect.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

You setup seems to be quite unusual, most HERMS systems I've seen have the coil inside the HLT, yours seems to work more like RIMS, but impossible to scorch the wort, best of both worldsI just wrapped copper pipe around a length of waste pipe to form the coil and put it into a 6 litre SS insulated soup/stew container and stuck an element through the bottom of the pot. There's loads of big SS catering pots for not much on flea bay, but most come from Germany or France.

. I had imagined copper pipe could kink/collapse if I tried coiling it like that. I wonder how tight a coil I could do, I've got some 4" tubing I could weld an end on to make a convenient container, saves having to buy a soup pot

. I had imagined copper pipe could kink/collapse if I tried coiling it like that. I wonder how tight a coil I could do, I've got some 4" tubing I could weld an end on to make a convenient container, saves having to buy a soup potI notice your sparge head is adjustable, do you lower it down to the liquid level when returning wort though it then raise it up for sparging? I've spent days googling trying to figure out why sparge and vorlauf inlets are different. I've finally read, literally in the last five minutes, about "hot side aeration". It seems you want to want to return wort back to the top of the mash tun gently without splashing so there's as little contact with the air as possible, but the sparge water doesn't matter, it just needs distributing over the whole surface to rinse all the sugars out. That had been confusing me for days.

daleyd

Member

- Messages

- 10,384

- Location

- Wrexham, North Wales

Not sure what they mean by “percent power output” but a PID controller can have an analogue output (ie infinitely variable for example 0-10 volts or 4-20 ma) or it can have a digital output, generally used with a time proportioning function. Most of the stuff I do will have an analogue output rather than digital.Just seen this video on a ready made system and at 10:40 they say the kettle PID controller is set for "percent power output" (So not PID at all). I can't figure out if these C100 controllers have that mode but if not, it wouldn't be hard to do it with an Arduino, almost the exact same code and circuit the pumps are running on actually.

PID really refers to how the control responds to the input and output and not a particular type of output.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

I assume it sets the duty of a PWM type signal output and ignores the input entirely.Not sure what they mean by “percent power output” but a PID controller can have an analogue output (ie infinitely variable for example 0-10 volts or 4-20 ma) or it can have a digital output, generally used with a time proportioning function. Most of the stuff I do will have an analogue output rather than digital.

brewdexta

The biggest tool in the box

- Messages

- 5,747

- Location

- UK

You setup seems to be quite unusual, most HERMS systems I've seen have the coil inside the HLT, yours seems to work more like RIMS, but impossible to scorch the wort, best of both worlds. I had imagined copper pipe could kink/collapse if I tried coiling it like that. I wonder how tight a coil I could do, I've got some 4" tubing I could weld an end on to make a convenient container, saves having to buy a soup pot

I notice your sparge head is adjustable, do you lower it down to the liquid level when returning wort though it then raise it up for sparging? I've spent days googling trying to figure out why sparge and vorlauf inlets are different. I've finally read, literally in the last five minutes, about "hot side aeration". It seems you want to want to return wort back to the top of the mash tun gently without splashing so there's as little contact with the air as possible, but the sparge water doesn't matter, it just needs distributing over the whole surface to rinse all the sugars out. That had been confusing me for days.

This is the heat exchanger build, first make a coil around some soil pipe. I can't remember the copper pipe size, probably 8 or 10mm

here's most of the components, I think I go the element from Backer. Instead of hose tails I now use QR fittings, I think all my plumbing bits came from BES. The sup

Here it is mostly complete

apart from the electrickery underneath. I put a cover on this later but don't have a picture handy.

and a neat cable entry, I used silicon sheathed cable

I can't find the 6l insulated pots on fleabay at the moment