mylesdw

Member

- Messages

- 797

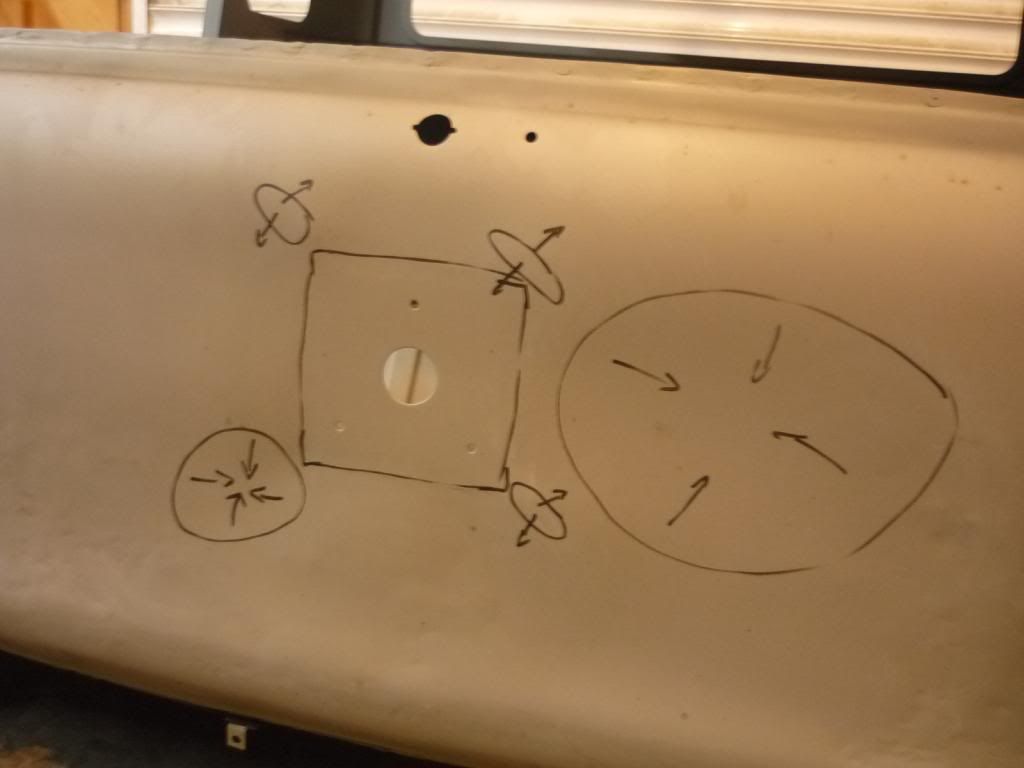

Trial fitting the front panel was quite tricky because it has returns on both sides where it wraps into the door shuts. You have to sort of spring it into place.

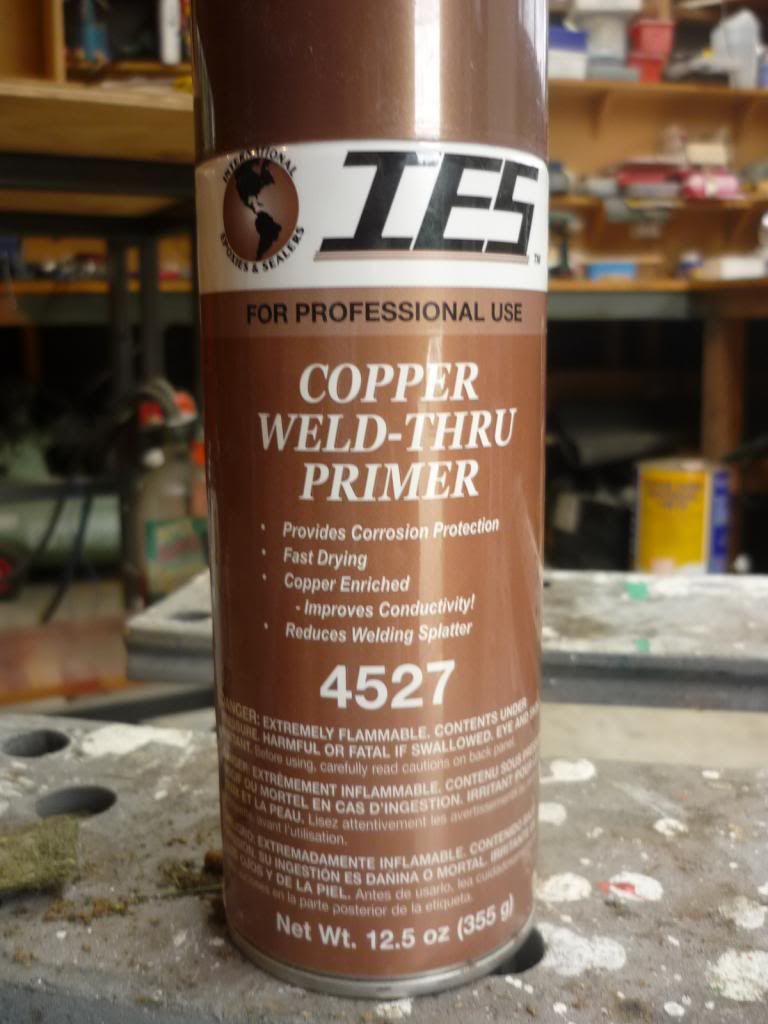

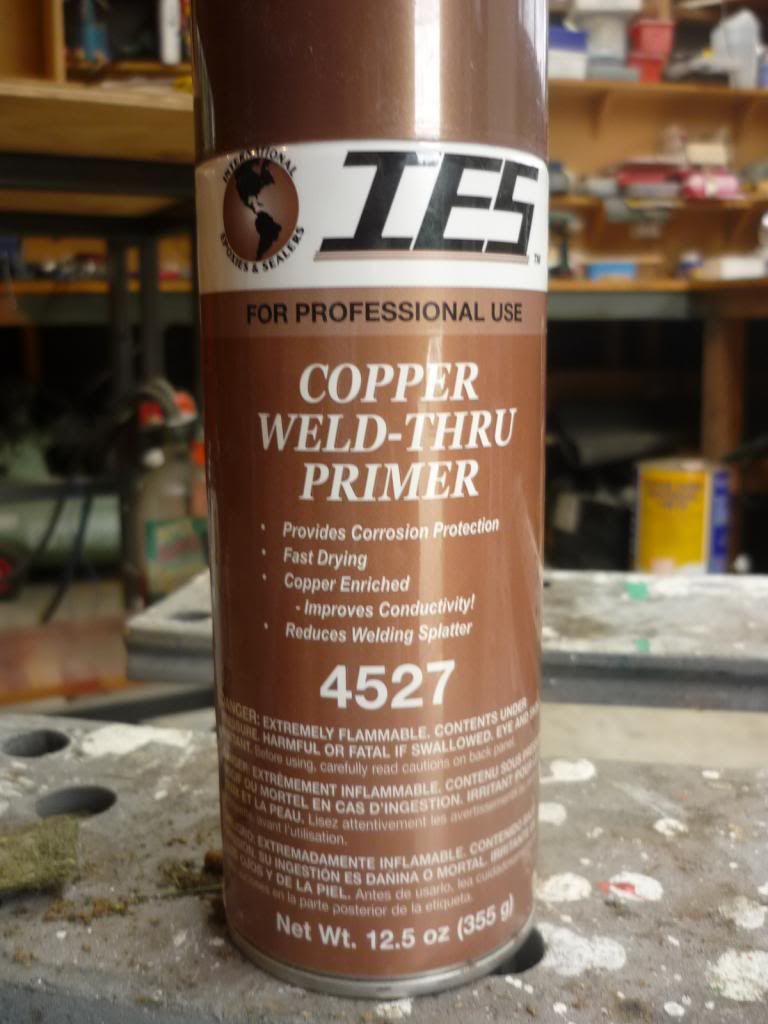

After a few goes and adjusting the flanges to get a nice close fit I removed the panel, cleaned up all the joining faces with a flap wheel and painted with this stuff:

t's a weld-through primer. I haven't used this before and I can't comment about its corrosion resistance but it seems to do exactly what it claims: it is very easy to weld through.

I clamped it all up with a number of mole-grips and started on the windscreen pillar corners because I reckon that these would be the most obvious if they don't align. The first thing I discovered was...

...lead! - where the original panel joint had been filled. It really doesn't weld very well but after a bit of heating and wiping and welding...

Then just a matter of plug-welding and grinding the 200 odd holes. It took me quite a while to get the technique and it still isn't that pretty but it all gets hidden by the grinder.

And finally it looks like this

After a few goes and adjusting the flanges to get a nice close fit I removed the panel, cleaned up all the joining faces with a flap wheel and painted with this stuff:

t's a weld-through primer. I haven't used this before and I can't comment about its corrosion resistance but it seems to do exactly what it claims: it is very easy to weld through.

I clamped it all up with a number of mole-grips and started on the windscreen pillar corners because I reckon that these would be the most obvious if they don't align. The first thing I discovered was...

...lead! - where the original panel joint had been filled. It really doesn't weld very well but after a bit of heating and wiping and welding...

Then just a matter of plug-welding and grinding the 200 odd holes. It took me quite a while to get the technique and it still isn't that pretty but it all gets hidden by the grinder.

And finally it looks like this

.

.