You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have fixed today

- Thread starter qwakers

- Start date

Not all today but I finished it today.

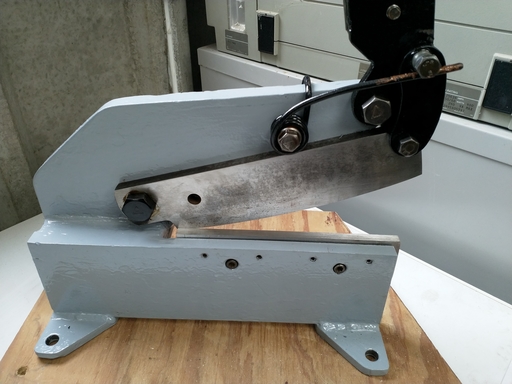

I started with this (it cost me £5.00 from an auction - nobody wanted it and the auctioneer started at a tenner and went down, I chipped in with a fiver expecting it to start but nobody else bit and I got it.) :-

It went through this :-

Also a belt linisher to clean the blades up and a lick of paint on the small parts and the body :-

To end up with this :-

After a bit of tweaking of the blade clearance I was well pleased with how it cut some test pieces :-

The red is 1.5mm, the next blue is part of an old up and over garage door that you can see the shear was working as a brake/folder - this was the 'before' picture and the four bottom bits are some of the same door after the rebuild when I was testing blade clearance.

Now if only I could get it to switch between shear/folder mode automatically

You can still buy these - they're about £100 inc. VAT - I don't know if they are exactly the same - this was all Whitworth threading, I suspect the current model will be using metric. The bolts were well worn and I probably should have gone and bought new but that's a project for another day.

I started with this (it cost me £5.00 from an auction - nobody wanted it and the auctioneer started at a tenner and went down, I chipped in with a fiver expecting it to start but nobody else bit and I got it.) :-

It went through this :-

Also a belt linisher to clean the blades up and a lick of paint on the small parts and the body :-

To end up with this :-

After a bit of tweaking of the blade clearance I was well pleased with how it cut some test pieces :-

The red is 1.5mm, the next blue is part of an old up and over garage door that you can see the shear was working as a brake/folder - this was the 'before' picture and the four bottom bits are some of the same door after the rebuild when I was testing blade clearance.

Now if only I could get it to switch between shear/folder mode automatically

You can still buy these - they're about £100 inc. VAT - I don't know if they are exactly the same - this was all Whitworth threading, I suspect the current model will be using metric. The bolts were well worn and I probably should have gone and bought new but that's a project for another day.

The Artilleryman

Member

- Messages

- 446

- Location

- Boston UK

Not a lot today, just bolted this to the floor & sorted the sticky stop button (neoprene boot split and dragging), only problem was I had to move my Tom Senior so I could get behind to do up the bolts.

Wedg1e

They call me Mr. Bodge-angles

- Messages

- 7,950

- Location

- Teesside, England

Not all today but I finished it today.

I started with this (it cost me £5.00 from an auction - nobody wanted it and the auctioneer started at a tenner and went down, I chipped in with a fiver expecting it to start but nobody else bit and I got it.) :-

View attachment 290548View attachment 290549

It went through this :-

View attachment 290562View attachment 290563

Also a belt linisher to clean the blades up and a lick of paint on the small parts and the body :-

View attachment 290564View attachment 290566

To end up with this :-

View attachment 290568View attachment 290569

After a bit of tweaking of the blade clearance I was well pleased with how it cut some test pieces :-

View attachment 290570

The red is 1.5mm, the next blue is part of an old up and over garage door that you can see the shear was working as a brake/folder - this was the 'before' picture and the four bottom bits are some of the same door after the rebuild when I was testing blade clearance.

Now if only I could get it to switch between shear/folder mode automatically

You can still buy these - they're about £100 inc. VAT - I don't know if they are exactly the same - this was all Whitworth threading, I suspect the current model will be using metric. The bolts were well worn and I probably should have gone and bought new but that's a project for another day.

Looks near-identical to the Peddinghaus I have; it was leaning against a skip and I asked if I could have it... Superman couldn't have opened and closed the van doors quicker

Fished a couple out of skips a while ago. Flogged one, kept the other. Someone had bodge welded a length of across the underside so it can be clamped in a vice to use - which does make it easy to get out and use, then put back out of the way.Looks near-identical to the Peddinghaus I have; it was leaning against a skip and I asked if I could have it... Superman couldn't have opened and closed the van doors quicker

Finally got round to fitting the woodworking vice that I got from @roblane65 . Before:

An hour later after 2 pots of tea and much sawing, chiselling, and violent swearing:

Have to have a trip to the great metropolis tomorrow as I'm out of suitable screws, then crack on and make some wooden jaws.

An hour later after 2 pots of tea and much sawing, chiselling, and violent swearing:

Have to have a trip to the great metropolis tomorrow as I'm out of suitable screws, then crack on and make some wooden jaws.

MattF

Forum Supporter

- Messages

- 18,537

- Location

- South Yorkshire

Bodged a chair repair as i couldn't get it too split apart and the 'low' setting was pants !

View attachment 290666

Bodged would be a compliment for that.

But, if you're going to do something..., & you've definitely done that with style.

But, if you're going to do something..., & you've definitely done that with style.

roblane65

Forum Supporter

- Messages

- 2,407

- Location

- Newcastle UK

looking goodFinally got round to fitting the woodworking vice that I got from @roblane65 . Before:

View attachment 291583

An hour later after 2 pots of tea and much sawing, chiselling, and violent swearing:

View attachment 291584

Have to have a trip to the great metropolis tomorrow as I'm out of suitable screws, then crack on and make some wooden jaws.

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,347

- Location

- Sevenoaks, UK

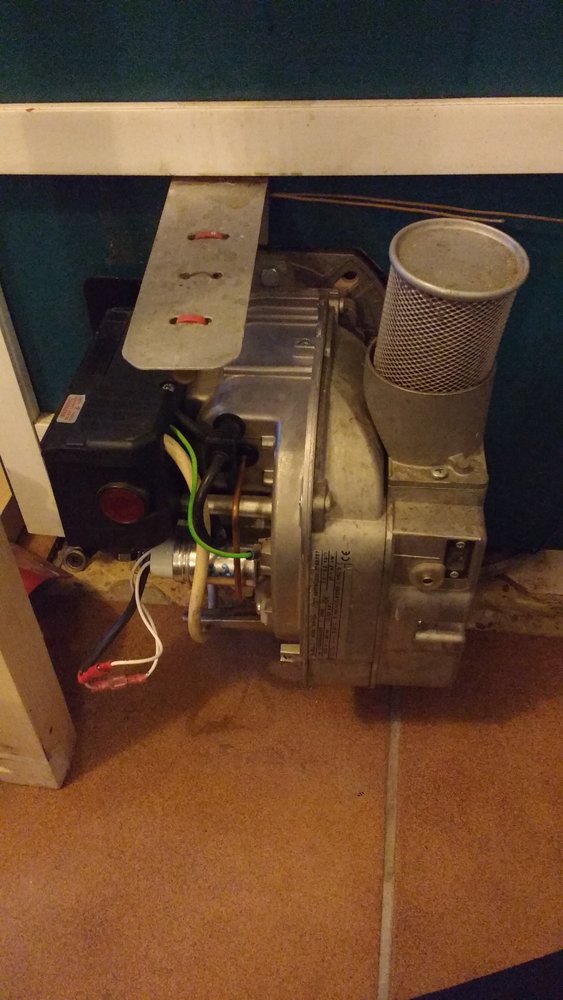

My oil boiler with a Riello boiler has been playing up and locking out for a while.

It's now like Trigger's Broom!

Back in February when it was playing up I fitted a new pump, new capacitor & new filter. It was better (less lockouts) until the last couple of days. I set the pump pressure back in Feb with a pressure gauge.

Today with my BiLs help fitted new bearings either end of the motor. The old SKF bearings took some getting off. They were 6202-2RS1/CNPLHT23. Tbh they didn't seem too bad once out...

The new, unbranded eBay ones pretty much slid on. I ended up nipping the motor shaft ends in the knurled vice jaws then putting the new bearings on with a bit of medium strength thread lock.

All back together and not missing a beat! (I rechecked the cap whilst stripped down). No more lock outs so far.

However...there's a background annoying, underlying buzz/whine that rises and falls. Maybe the cheapo bearings?

Tbh, in where the photocell was pretty dirty, though the photocell was clean (I've checked it a few times). Hoovered all that out and cleaned all the internal faces with a dry toothbrush.

Did find the plastic coupling that goes between the pump and motor a bit worn as well so a new one ordered.

Maybe I should have just cleaned in there and tried with the old bearings!

It's now like Trigger's Broom!

Back in February when it was playing up I fitted a new pump, new capacitor & new filter. It was better (less lockouts) until the last couple of days. I set the pump pressure back in Feb with a pressure gauge.

Today with my BiLs help fitted new bearings either end of the motor. The old SKF bearings took some getting off. They were 6202-2RS1/CNPLHT23. Tbh they didn't seem too bad once out...

The new, unbranded eBay ones pretty much slid on. I ended up nipping the motor shaft ends in the knurled vice jaws then putting the new bearings on with a bit of medium strength thread lock.

All back together and not missing a beat! (I rechecked the cap whilst stripped down). No more lock outs so far.

However...there's a background annoying, underlying buzz/whine that rises and falls. Maybe the cheapo bearings?

Tbh, in where the photocell was pretty dirty, though the photocell was clean (I've checked it a few times). Hoovered all that out and cleaned all the internal faces with a dry toothbrush.

Did find the plastic coupling that goes between the pump and motor a bit worn as well so a new one ordered.

Maybe I should have just cleaned in there and tried with the old bearings!

8ob

Member

- Messages

- 14,286

- Location

- Nescient in the vale

Not really fixed but fixing because they sent out the wrong bearings ,resume on Monday .

267 × 200

267 × 200

Chipper bearings gone at 500 hours so going to convert them to greaseable.

This is one the same I converted in 2016 to greasable, not been a moments trouble. Removed the shaft for inspection today

267 × 200

267 × 200Chipper bearings gone at 500 hours so going to convert them to greaseable.

This is one the same I converted in 2016 to greasable, not been a moments trouble. Removed the shaft for inspection today

Red'n'Black

Forum Supporter

- Messages

- 770

- Location

- Malvern, Worcs

Sealed bearings don’t last 5 minutes

edit: well 30,000 minutes lol

Is it that the open bearings get re-greased (assuming the machine is maintained properly) so last longer? Or something else?

One up-coming job is to replace the motor bearings in the compressor, I was going to get the sealed type but you've got me thinking now.

Not really fixed but fixing because they sent out the wrong bearings ,resume on Monday .

267 × 200

Chipper bearings gone at 500 hours so going to convert them to greaseable.

This is one the same I converted in 2016 to greasable, not been a moments trouble. Removed the shaft for inspection today

Anything in the manual suggesting when they ought to be replaced?

Regular greasing, like old cars (ie 1920, 30 etc), forces out the crap that gets in, pushes old contaminated grease out.

We try and design for 50,000 hrs between major maintenance - on major bought in design on a project I was was on a couple of years ago, theory said we'd get 38. Management said that might be okay . . . No, I said, 38 hours! Not 38,000 hrs! Took a year to redesign to get theory up high enough to be worth doing.

I'm a big fan of regreasable bearings, and are definitely better in a lot of cases, problem is that the guy with the grease gun needs to know what he's doing. depends on bearing type and installation. Too much grease is often just as bad as not enough...

Had a back to back offshore years ago, could always tell when he'd greased a fan bearing, they were running mad hot, old style plummer blocks with top caps, he pumped in grease until it was full everywhere. Always the same solution, shut everything down, remove about 1/3 of the grease, back to normal running temperature again. He must have been told a hundred times, manufacturers lube schedule called for a block 2/3 full, then 6 monthly add a couple of shots, but he just couldn't (wouldn't) get his head round it....

Had a back to back offshore years ago, could always tell when he'd greased a fan bearing, they were running mad hot, old style plummer blocks with top caps, he pumped in grease until it was full everywhere. Always the same solution, shut everything down, remove about 1/3 of the grease, back to normal running temperature again. He must have been told a hundred times, manufacturers lube schedule called for a block 2/3 full, then 6 monthly add a couple of shots, but he just couldn't (wouldn't) get his head round it....

8ob

Member

- Messages

- 14,286

- Location

- Nescient in the vale

Anything in the manual suggesting when they ought to be replaced?

Regular greasing, like old cars (ie 1920, 30 etc), forces out the crap that gets in, pushes old contaminated grease out.

We try and design for 50,000 hrs between major maintenance - on major bought in design on a project I was was on a couple of years ago, theory said we'd get 38. Management said that might be okay . . . No, I said, 38 hours! Not 38,000 hrs! Took a year to redesign to get theory up high enough to be worth doing.

Nothing in any of the service/user manuals, typical use with standard bearings would be about 750 hours. Feeding them with sweepings, fencing wire and running blunt knives doesn't help.

I'm a big fan of regreasable bearings, and are definitely better in a lot of cases, problem is that the guy with the grease gun needs to know what he's doing. depends on bearing type and installation. Too much grease is often just as bad as not enough...

Had a back to back offshore years ago, could always tell when he'd greased a fan bearing, they were running mad hot, old style plummer blocks with top caps, he pumped in grease until it was full everywhere. Always the same solution, shut everything down, remove about 1/3 of the grease, back to normal running temperature again. He must have been told a hundred times, manufacturers lube schedule called for a block 2/3 full, then 6 monthly add a couple of shots, but he just couldn't (wouldn't) get his head round it....

May be the case with bearings running in a controlled environment, for any kit we run the "over grease" as @bricol says is the only thing pumping out the contaminated grease/grit out of bearings/bushes. The 500 hours the standard sealed bearing ran to vs the 2000+ hours of the greasable conversion sort of proves the point considering its a back to back comparison of the same machine doing the same job. All I have done here is remove the inner seals from the sealed bearings and installed a grease nipple in the centre of the hub so the hub acts as a big grease reservoir.

Bob

Bob

Nothing in any of the service/user manuals, typical use with standard bearings would be about 750 hours. Feeding them with sweepings, fencing wire and running blunt knives doesn't help.

May be the case with bearings running in a controlled environment, for any kit we run the "over grease" as @bricol says is the only thing pumping out the contaminated grease/grit out of bearings/bushes. The 500 hours the standard sealed bearing ran to vs the 2000+ hours of the greasable conversion sort of proves the point considering its a back to back comparison of the same machine doing the same job. All I have done here is remove the inner seals from the sealed bearings and installed a grease nipple in the centre of the hub so the hub acts as a big grease reservoir.

Bob

Bob

no point to prove Bob, I agree with you. In your case, it's the perfect solution, flushing out the contaminants and giving fresh grease is without doubt the best option, as long as the grease and heat has somewhere to go and it's more controllable. The advantage is you know what you're doing and have worked your system to suit your application, unfortunately that's not always the case...

The point I was making is that in some applications, too much can cause problems, in our case it caused over heating as it had nowhere to go.

8ob

Member

- Messages

- 14,286

- Location

- Nescient in the vale

in our case it caused over heating as it had nowhere to go.

That makes sense, with all of our kit I dont think I have ever seen a seal on anything that doesnt just spew out the excess

Bob