You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Olderisbetter

Member

- Messages

- 3,982

- Location

- Wolverhampton

Made a jig and holder for 5 inch sanding discs out of some dowels and a bit of timber it works quite average

ajlelectronics

Forum Supporter

- Messages

- 11,156

- Location

- Gloucester, England

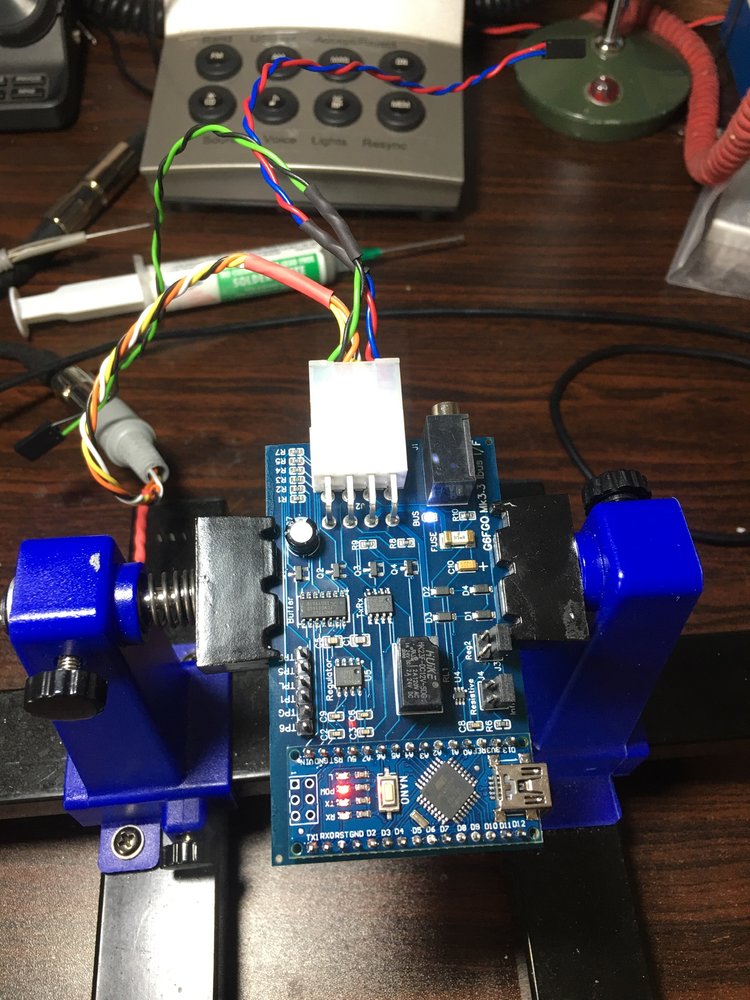

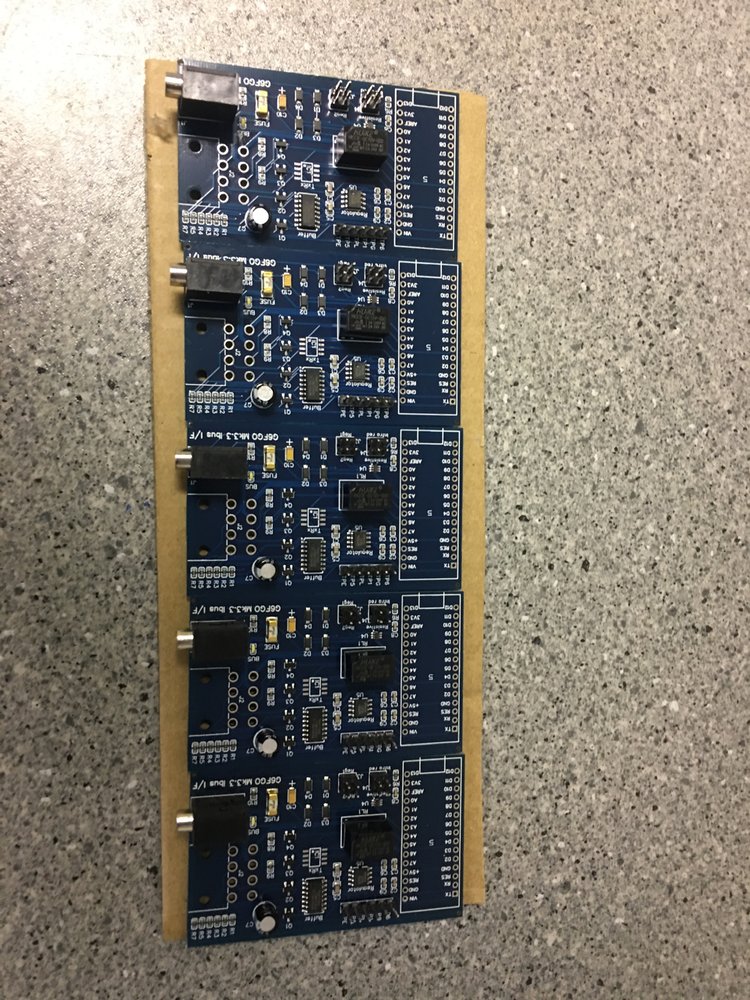

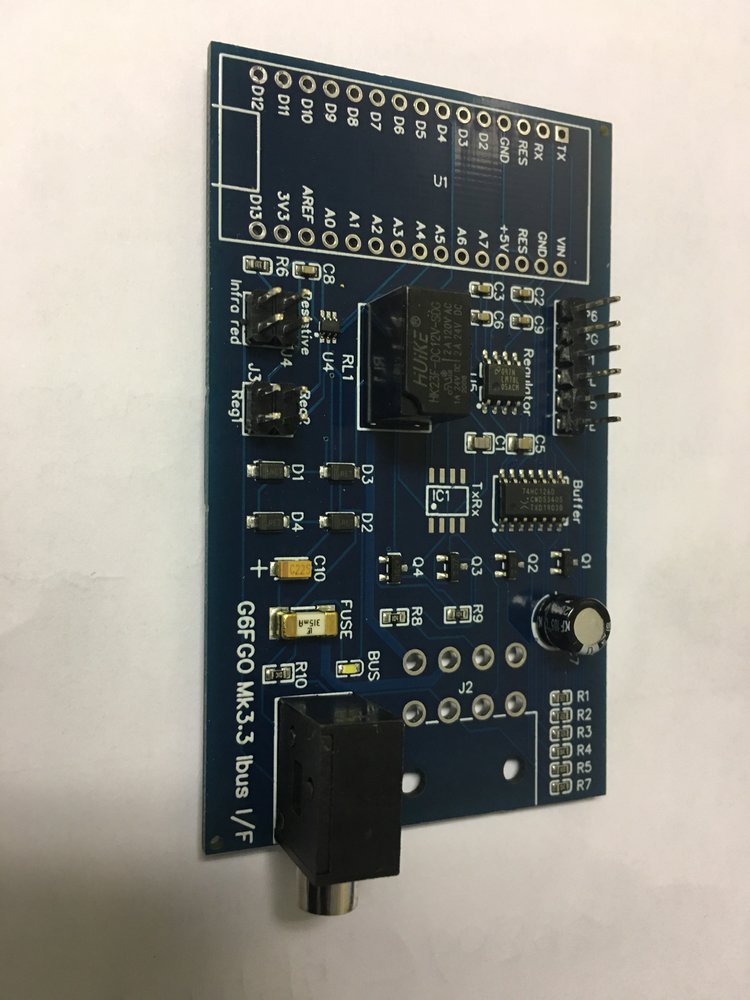

Five of my next batch of Ibus radio converters. I have twenty to do, but these have taken me all day! One didn't function properly so I had to rework it.

My Old Landy

Engineering Mayhem

- Messages

- 3,506

- Location

- North Lincs

I had to clean up my hot works area today so I could do some hardening. I made a grill for using the plasma (and to fill the hole I put in the bench a year ago!)

Quite pleased with it and the fact I actually did some welding

Quite pleased with it and the fact I actually did some welding

qwakers

Member

- Messages

- 2,717

- Location

- cornwall, united kingdom

finishing touchpit metalwork painted.

that's it bar the ladder and the cover.

roofman

Purveyor of fine English buckets and mops

- Messages

- 13,062

- Location

- North West with water on 3 sides

Recently picked up a very heavy cast iron table from zzr1200 but needed it a bit mobile so pics tell todays story ..My old Safmig was right on its limits but just about got enough heat in to get the job done

..My old Safmig was right on its limits but just about got enough heat in to get the job done (incidentally the best welder ive ever owned and ive had a few over the years). Dont know what John thinks but this thing must be close to 350KG.

(incidentally the best welder ive ever owned and ive had a few over the years). Dont know what John thinks but this thing must be close to 350KG.

..My old Safmig was right on its limits but just about got enough heat in to get the job done

..My old Safmig was right on its limits but just about got enough heat in to get the job done (incidentally the best welder ive ever owned and ive had a few over the years). Dont know what John thinks but this thing must be close to 350KG.

(incidentally the best welder ive ever owned and ive had a few over the years). Dont know what John thinks but this thing must be close to 350KG.

Kram

Member

- Messages

- 8,460

- Location

- Sussex

I had some good results with silverflow 55 brazing with mapp recently so had another go at the er40 collet chuck. Well it sticks, took a bloody lot of heat and still was not quite hot enough to flow properly. Ive got some ideas, I might try reheating it tomorrow, but I think itll be good enough. Does mean I'll need to face and recut the taper.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,495

- Location

- France, Brittany.

That's a rather nice looking workshop... Ooph.Recently picked up a very heavy cast iron table from zzr1200 but needed it a bit mobile so pics tell todays story..My old Safmig was right on its limits but just about got enough heat in to get the job done

(incidentally the best welder ive ever owned and ive had a few over the years). Dont know what John thinks but this thing must be close to 350KG.

View attachment 284728 View attachment 284729 View attachment 284730 View attachment 284731 View attachment 284732 View attachment 284733

So tidy, so organised....

Blake's 7

Member

- Messages

- 205

- Location

- Ireland

I welded the blade of a 38 mm woodworking chisel to the shaft of an SDS masonry bit in order to use the hammer action of my Dewalt drill to chop out the scaffolding planks I used in the shuttering for the concrete head over my new fireplace. The planks are new, 3 inches thick, and a very tight fit with no way to remove them but to break them out of the fireplace bit by bit. I didn't fancy the idea of doing it by hand with a hammer and chisel so this was the solution I came up with and it works brilliantly. What you see in the second and third photo only took me a few minutes to do.

The galvanised hook is one of a pair with its counterpart on the opposite side of the fireplace. Both hooks are welded to lengths of rebar several inches long which are projecting up through the timber and are now firmly encased in the new concrete head of the fireplace. In the future the hooks can be used to support a steel bar from which I can hang cast iron kettles and pots. Incorporating the hooks into the shuttering before pouring the concrete avoids having to drill the underside of the slab afterwards.

The galvanised hook is one of a pair with its counterpart on the opposite side of the fireplace. Both hooks are welded to lengths of rebar several inches long which are projecting up through the timber and are now firmly encased in the new concrete head of the fireplace. In the future the hooks can be used to support a steel bar from which I can hang cast iron kettles and pots. Incorporating the hooks into the shuttering before pouring the concrete avoids having to drill the underside of the slab afterwards.

Edward Teach

pre-moderated

- Messages

- 992

- Location

- South West England

How about drilling holes through, across the width of the planks.I welded the blade of a 38 mm woodworking chisel to the shaft of an SDS masonry bit in order to use the hammer action of my Dewalt drill to chop out the scaffolding planks I used in the shuttering for the concrete head over my new fireplace. The planks are new, 3 inches thick, and a very tight fit with no way to remove them but to break them out of the fireplace bit by bit. I didn't fancy the idea of doing it by hand with a hammer and chisel so this was the solution I came up with and it works brilliantly. What you see in the second and third photo only took me a few minutes to do.

View attachment 284759

View attachment 284760

View attachment 284761

View attachment 284764

The galvanised hook is one of a pair with its counterpart on the opposite side of the fireplace. Both hooks are welded to lengths of rebar several inches long which are projecting up through the timber and are now firmly encased in the new concrete head of the fireplace. In the future the hooks can be used to support a steel bar from which I can hang cast iron kettles and pots. Incorporating the hooks into the shuttering before pouring the concrete avoids having to drill the underside of the slab afterwards.

Memmeddu

Member

- Messages

- 5,808

- Location

- Italia Sardegna

So today has been a long morning .

Makita HM0871C demolition Hammer.

Replaced the stator windings, armature ,carbon brushes, cleaned all the parts as well as I could (I still not able to make miracles happen ), new o rings and gaskets ,new lube,new tool retainer lugs, new cylinder seats ,new Seeger,new ball bearings, new powercord .

), new o rings and gaskets ,new lube,new tool retainer lugs, new cylinder seats ,new Seeger,new ball bearings, new powercord .

Had to go to the car parts store to buy a 6201V ball bearing because it wasn't included with the armature .

Lost an half hour there.

Then coming back home ,an old cyclist made me get upset as well ....

3 km with my car at 10km/h and him always in front of me .

Then once home I've touched another car while parking (no damages )

Finished to assemble this thing at 2pm .

That's will hopefully write the end of a repair lasted three months .

I've disassembled this thing in January or first days of February , ordered the parts and waited them till yesterday .

130 euros worth of parts and consumables .

50 of profit .

I'm too honest I believe

Makita HM0871C demolition Hammer.

Replaced the stator windings, armature ,carbon brushes, cleaned all the parts as well as I could (I still not able to make miracles happen

), new o rings and gaskets ,new lube,new tool retainer lugs, new cylinder seats ,new Seeger,new ball bearings, new powercord .

), new o rings and gaskets ,new lube,new tool retainer lugs, new cylinder seats ,new Seeger,new ball bearings, new powercord .Had to go to the car parts store to buy a 6201V ball bearing because it wasn't included with the armature .

Lost an half hour there.

Then coming back home ,an old cyclist made me get upset as well ....

3 km with my car at 10km/h and him always in front of me .

Then once home I've touched another car while parking (no damages )

Finished to assemble this thing at 2pm .

That's will hopefully write the end of a repair lasted three months .

I've disassembled this thing in January or first days of February , ordered the parts and waited them till yesterday .

130 euros worth of parts and consumables .

50 of profit .

I'm too honest I believe

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

As soon as it's confirmed that a new armature is needed.. it's usually uneconomical to repair the equipment and make a sensible profit . You can get customers all day long and well into the night who demand Rolls Royce repairs at the scrap yard prices plus they'll want a six months warrantee on your repairs .So today has been a long morning .

Makita HM0871C demolition Hammer.

Replaced the stator windings, armature ,carbon brushes, cleaned all the parts as well as I could (I still not able to make miracles happen), new o rings and gaskets ,new lube,new tool retainer lugs, new cylinder seats ,new Seeger,new ball bearings, new powercord .

Had to go to the car parts store to buy a 6201V ball bearing because it wasn't included with the armature .

Lost an half hour there.

Then coming back home ,an old cyclist made me get upset as well ....

3 km with my car at 10km/h and him always in front of me .

Then once home I've touched another car while parking (no damages )

Finished to assemble this thing at 2pm .

That's will hopefully write the end of a repair lasted three months .

I've disassembled this thing in January or first days of February , ordered the parts and waited them till yesterday .

130 euros worth of parts and consumables .

50 of profit .

I'm too honest I believe

View attachment 284818 View attachment 284819 View attachment 284820 View attachment 284821 View attachment 284822 View attachment 284823 View attachment 284824 View attachment 284825 View attachment 284826

In our plant hire company once the cost of a repair came close to the cost of a new machine there is no way I'd repair it if it was small plant under £ 1200 . Just phone the guy to come and look at what's wrong with it .See if you can get a trade account with a main dealer so you can say just how uneconomical it would be to repair .. You can then offer a brand new 1,2 or 3 years warranteed replacement equipment and if you've made your sums add up properly you'll have a few euros profit for very little work ..don't reassemble the old equipment ..it's more time out of you life you won't get back .

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

I'm a sentimental old git and a half .

Today spent the best part of two hours over a period of four hours carefully marking , cutting , shaping , filing a very hard hickory pitchfork shaft so I could put a 40yr old ladies Wilkinson's stainless steel border spade on it . The spade used to belong to an ancient long dead aunt . She died 27 years ago & had a special place in my heart as she was a lot more than a guiding light in my life . It's been moved unused in several house moves , last week I finally decided to hand my old gardening tools over to my son in law Ed so he can attempt to provide food for himself & my daughter as they have a large garden at the place they are renting. ( I cant use a normal spade any more as I can't bend my spine very much ) .

Normally such a thing would be a breeze but this old border spade had the cup for the shaft shaped like an old fashioned lipped coal scuttle that ran some 100 mm up the shaft above the lowest part of the cup & it was a 5 mm smaller fit than the diameter of the pitchfork shaft. (So was the old shaft I took out ) .

Even worse is the end being shaped was not the standard single taper but two tapers like a carrot shaped dogs leg. Many soot smoke test fits & lots of rasp & chisel work later it was within 1/4 of an inch of a good fit , so I mixed up two small tubes of araldite , coated the now shaped shaft end & turned the spade upside down and gave the end of the shaft a hefty wallop onto a thick pad of Delrin ..it went in beautifully . Tomorrow it should be well set & cured .. then starts the task of forming two stainless or bright steel rivets to really get things nice & tight ,a good fine sanding then three coats of linseed oil a couple of days apart to give me a really nice long handled spade I can use .

The old long handled spade , fork , light rake & light long handled hoe was given to me FOC by Bulldog tools in April 1982 . The blade was 9 inches long when I got it .. when I gave it to Ed ... the blade is just over 6 & 1/2 inches long with both corners well rounded . The rh side being more like a long French curve due to the way I've used it over the years .

Today spent the best part of two hours over a period of four hours carefully marking , cutting , shaping , filing a very hard hickory pitchfork shaft so I could put a 40yr old ladies Wilkinson's stainless steel border spade on it . The spade used to belong to an ancient long dead aunt . She died 27 years ago & had a special place in my heart as she was a lot more than a guiding light in my life . It's been moved unused in several house moves , last week I finally decided to hand my old gardening tools over to my son in law Ed so he can attempt to provide food for himself & my daughter as they have a large garden at the place they are renting. ( I cant use a normal spade any more as I can't bend my spine very much ) .

Normally such a thing would be a breeze but this old border spade had the cup for the shaft shaped like an old fashioned lipped coal scuttle that ran some 100 mm up the shaft above the lowest part of the cup & it was a 5 mm smaller fit than the diameter of the pitchfork shaft. (So was the old shaft I took out ) .

Even worse is the end being shaped was not the standard single taper but two tapers like a carrot shaped dogs leg. Many soot smoke test fits & lots of rasp & chisel work later it was within 1/4 of an inch of a good fit , so I mixed up two small tubes of araldite , coated the now shaped shaft end & turned the spade upside down and gave the end of the shaft a hefty wallop onto a thick pad of Delrin ..it went in beautifully . Tomorrow it should be well set & cured .. then starts the task of forming two stainless or bright steel rivets to really get things nice & tight ,a good fine sanding then three coats of linseed oil a couple of days apart to give me a really nice long handled spade I can use .

The old long handled spade , fork , light rake & light long handled hoe was given to me FOC by Bulldog tools in April 1982 . The blade was 9 inches long when I got it .. when I gave it to Ed ... the blade is just over 6 & 1/2 inches long with both corners well rounded . The rh side being more like a long French curve due to the way I've used it over the years .

Last edited:

Memmeddu

Member

- Messages

- 5,808

- Location

- Italia Sardegna

Makita parts are pretty cheap.As soon as it's confirmed that a new armature is needed.. it's usually uneconomical to repair the equipment and make a sensible profit . You can get customers all day long and well into the night who demand Rolls Royce repairs at the scrap yard prices plus they'll want a six months warrantee on your repairs .

In our plant hire company once the cost of a repair came close to the cost of a new machine there is no way I'd repair it if it was small plant under £ 1200 . Just phone the guy to come and look at what's wrong with it .See if you can get a trade account with a main dealer so you can say just how uneconomical it would be to repair .. You can then offer a brand new 1,2 or 3 years warranteed replacement equipment and if you've made your sums add up properly you'll have a few euros profit for very little work ..don't reassemble the old equipment ..it's more time out of you life you won't get back .

And those HM0XXX are pretty easy to work on .

Customer is happy I'm happy little bit today it's better than nothing tomorrow , expecially these days.

Total repair costs is way less than 35% economical value of the new tool.

That's my limit 35% not more than that because it's not fair for the customer .

If the customer is particularly intended to repair the tool even if over this limit , I firstly try to explain that it's not worth, and if he still wants to repair it I'll do it .

Maker

Most folk just call me; Orange Joe

- Messages

- 10,649

- Location

- Keeler crater

Made a knob

View attachment 282176

It's a handle for a cast iron casserole pan, the original was some brittle plastic and broke months ago. I did the bottom with a form tool ground from a parting blade on it's side, couldn't be bothered to grind a concave tool for the top so that was just freehand with a big corner radius tool and a file.M6 thread in the bottom to hold it to the lid and to conveniently hold it for turning the top face, it probably wouldn't have held up to the cutting force on an inch long form tool anyway.

Seems to work.

Woody.v8

Blue gluer

- Messages

- 4,213

- Location

- staffs

The last time I saw legs like that they was hanging out of the edge of a nestWhomever those legs belong to, tell them to do everyone a favour & wear trousers.

- Messages

- 13,490

- Location

- England

That is a very nice one!Present for someone.

View attachment 284583

Been a few years since I last made one, I'm quite pleased with it.