zx9

Forum Supporter

- Messages

- 5,187

- Location

- South East London

After been inspired by @MattF in the relaxed turning thread, today I finished turning these.

Into a tool post drill guide.

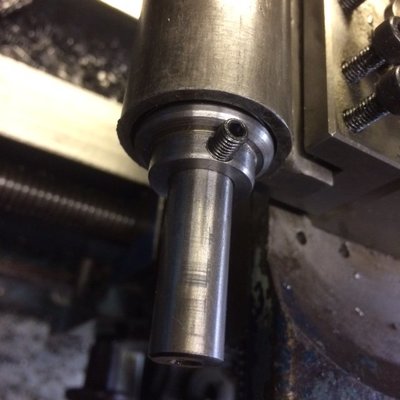

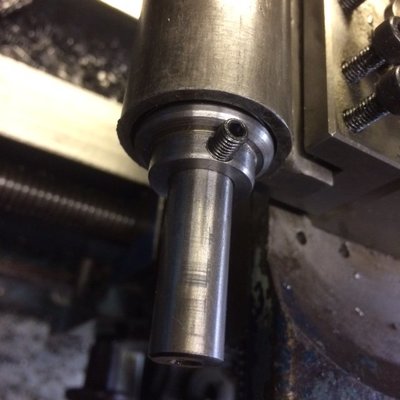

And a better view of the guide.

The body was turned from a bit of scrap water barrel which is welded to a 10x 12.5mm mild steel strip, I should have gone 10x 15mm to give more room for the fillet or got more argon for the tig and done it a bit tidier. Not shown in the first photo are a couple of thrust bearings though really only the front one is needed as I shall be using the cross slide to put on the feed.

Last photo is the back locating ring with the first hole I have drilled using the drill guide, I just need a shorter 5mm grub screw to finish it off.

And this is why I have a sudden need for stub drills.

Into a tool post drill guide.

And a better view of the guide.

The body was turned from a bit of scrap water barrel which is welded to a 10x 12.5mm mild steel strip, I should have gone 10x 15mm to give more room for the fillet or got more argon for the tig and done it a bit tidier. Not shown in the first photo are a couple of thrust bearings though really only the front one is needed as I shall be using the cross slide to put on the feed.

Last photo is the back locating ring with the first hole I have drilled using the drill guide, I just need a shorter 5mm grub screw to finish it off.

And this is why I have a sudden need for stub drills.