Pete.

Member

- Messages

- 15,074

- Location

- Kent, UK

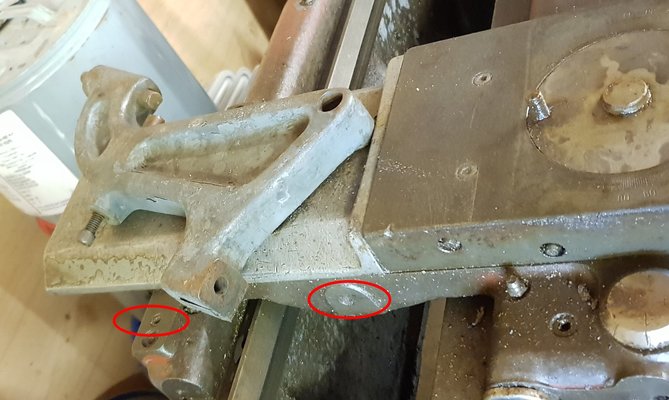

Yes you ought to adjust that saddle gib using the slotted adjuster. I've never done it but it seems pretty intuitive. Loosen the cap screw, turn the adjuster to the left, tighten cap screw I should think. Keep adjusting until you get no lift and then check you have full travel without sticking.

The thing to remember is that the underside of the saddle ways on all machines will wear at the ends first, so you get a hump in the middle that allows the saddle to rock. Adjusting that gib will hold the left side of it down and steady any tiny rocking motion.

Loose headstock bearings you check for by putting a dial gauge on the spindle behind the chuck and lifting the chuck with a lever to see what movement you get.

The thing to remember is that the underside of the saddle ways on all machines will wear at the ends first, so you get a hump in the middle that allows the saddle to rock. Adjusting that gib will hold the left side of it down and steady any tiny rocking motion.

Loose headstock bearings you check for by putting a dial gauge on the spindle behind the chuck and lifting the chuck with a lever to see what movement you get.