Brad93

Member

- Messages

- 17,551

- Location

- Essex, United Kingdom

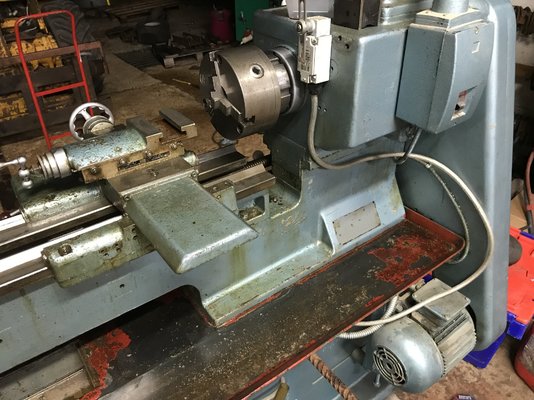

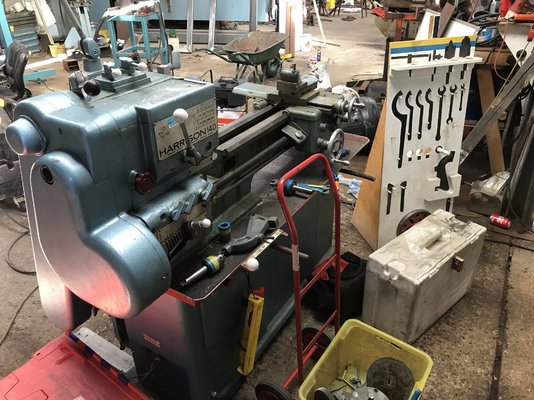

Picked the lathe up yesterday. It came out of a school in Croydon, where I think it has been from new.

Got most of the accessories it would of had from new:

Some damage to the L00 taper.

Some damage to the compound.

Damage to one of the screws of the four jaw.

Damage to a jaw of the 3 jaw.

Some Pics:

Got most of the accessories it would of had from new:

- Three Jaw

- Four Jaw

- Faceplate

- MT4.5 > MT3 Taper Adapter

- Travelling Steady

- Live centre

- Jacobs Chuck

- Coolant Pump

- Lovolite

- Changewheels

- Splash back

- Chuck guard

- All the C-Spanner’s and Chuck Keys

Some damage to the L00 taper.

Some damage to the compound.

Damage to one of the screws of the four jaw.

Damage to a jaw of the 3 jaw.

Some Pics:

-

9E1A9CB6-7FB3-44E6-81BE-907290143EED.jpeg218.7 KB · Views: 138

9E1A9CB6-7FB3-44E6-81BE-907290143EED.jpeg218.7 KB · Views: 138 -

733B15C6-0868-4275-AB57-270C74D9F5BB.jpeg270.7 KB · Views: 118

733B15C6-0868-4275-AB57-270C74D9F5BB.jpeg270.7 KB · Views: 118 -

6DC5F2BD-EDDD-4178-A59F-6C3B371DC7D8.jpeg235.3 KB · Views: 120

6DC5F2BD-EDDD-4178-A59F-6C3B371DC7D8.jpeg235.3 KB · Views: 120 -

6C5AFA74-EE54-4232-BD01-FBD3F8D321A5.jpeg599.6 KB · Views: 118

6C5AFA74-EE54-4232-BD01-FBD3F8D321A5.jpeg599.6 KB · Views: 118 -

F4AE9D11-3368-428D-9C75-BA53243A1A2D.jpeg614.2 KB · Views: 144

F4AE9D11-3368-428D-9C75-BA53243A1A2D.jpeg614.2 KB · Views: 144 -

B264D9CF-E9E8-4D98-B23E-D604689982A2.jpeg382.1 KB · Views: 130

B264D9CF-E9E8-4D98-B23E-D604689982A2.jpeg382.1 KB · Views: 130 -

366606FE-FBF2-4119-ADDC-CAB1BD425C02.jpeg281.9 KB · Views: 130

366606FE-FBF2-4119-ADDC-CAB1BD425C02.jpeg281.9 KB · Views: 130 -

3F7AB5EF-6110-4CCF-A7B9-FD68019BCFA2.jpeg400.4 KB · Views: 124

3F7AB5EF-6110-4CCF-A7B9-FD68019BCFA2.jpeg400.4 KB · Views: 124 -

851F64AA-599A-40F2-8B42-AECC762A1311.jpeg299.2 KB · Views: 127

851F64AA-599A-40F2-8B42-AECC762A1311.jpeg299.2 KB · Views: 127