Sorry, but I don't understand. I appreciate that the clamp and tip swap polarity for the two modes, but I can't tell which lead goes to which.

I think there may be a misprint in the brochure.

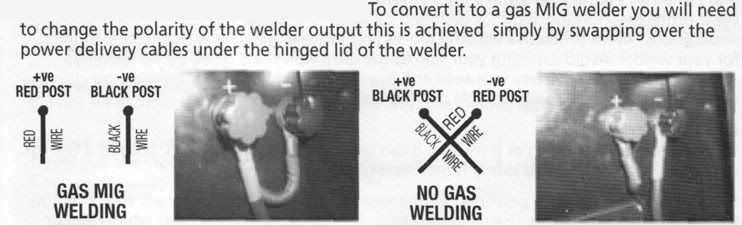

For gas welding:

- red wire to post marked +ve

- black wire to post marked -ve

For gasless welding:

Just swap them over, i.e.

- black wire to post marked +ve

- red wire to post marked -ve

It couldn't be simpler!