You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wolf MIG Welders

- Thread starter mr pick

- Start date

rtbcomp

Moderator

- Messages

- 18,549

- Location

- Sheffield UK

The most difficult part to convert Live Torch to Non-Live Torch would be running a wire up the torch and providing a switch on the torch. If they've omitted a contactor on cost grounds they will use a gas valve in the torch rather than a solenoid valve.

On a basic machine a two-pole contactor in the mains leads lead to the transformer should do the trick.

You will also have to provide a low voltage power supply to energise the contactor coil, don't use a mains voltage coil as you don't want mains in the torch.

Next they'll be using clockwork motors in the wire feed

On a basic machine a two-pole contactor in the mains leads lead to the transformer should do the trick.

You will also have to provide a low voltage power supply to energise the contactor coil, don't use a mains voltage coil as you don't want mains in the torch.

Next they'll be using clockwork motors in the wire feed

Won't there already be a switch there to switch the wire feed on and off?The most difficult part to convert Live Torch to Non-Live Torch would be running a wire up the torch and providing a switch on the torch.

rtbcomp

Moderator

- Messages

- 18,549

- Location

- Sheffield UK

Won't there already be a switch there to switch the wire feed on and off?

Just making sure you were awake

andy_burnton

Newbie

- Messages

- 3

Another Live Torch machine.

Hi guys,

I recently got a Sealey Mightymig 100 MKII off eBay to do a wee bit of welding on daughter's exhaust and it is a live torch as well. That little piece of information wasn't in the advert (surprise, surprise).

I did think about putting a relay in it. I think the wire feed motor is a small DC one, so could probably take that through a diode to operate the relay.

If I get around to it I'll post some photos and details.

Cheers,

Andy

Hi guys,

I recently got a Sealey Mightymig 100 MKII off eBay to do a wee bit of welding on daughter's exhaust and it is a live torch as well. That little piece of information wasn't in the advert (surprise, surprise).

I did think about putting a relay in it. I think the wire feed motor is a small DC one, so could probably take that through a diode to operate the relay.

If I get around to it I'll post some photos and details.

Cheers,

Andy

rtbcomp

Moderator

- Messages

- 18,549

- Location

- Sheffield UK

Don't feed the relay coil from the motor connections, the voltage varies according to motor speed and the relay may not call at lower speeds, you'll need to power the relay from the trigger or the supply to the motor control PCB. You really need the circuit diagram.

You could use a relay to call the contactor, but there will be a time delay from pulling the trigger to the torch coming live, although I guess this would be insignificant.

You could use a relay to call the contactor, but there will be a time delay from pulling the trigger to the torch coming live, although I guess this would be insignificant.

Last edited:

andy_burnton

Newbie

- Messages

- 3

LIve torch

Hi guys,

Thanks for that RTBComp.

What I was actually thinking of was using a feed from the motor via a diode to the base of a switching transistor ( that only needs 0.6v to switch it on ). The relay would be in the collector feed of the tranny. Can you see any flaws in that ?

Cheers,

Andy

Hi guys,

Thanks for that RTBComp.

What I was actually thinking of was using a feed from the motor via a diode to the base of a switching transistor ( that only needs 0.6v to switch it on ). The relay would be in the collector feed of the tranny. Can you see any flaws in that ?

Cheers,

Andy

rtbcomp

Moderator

- Messages

- 18,549

- Location

- Sheffield UK

That's probably the simplest way, but I don't do simple if I can help it

You're best using a switching transistor, these switch hard on for a range of input voltages, a normal tranny conducts according to the base voltage, as in the motor speed circuit I referred to.

Put a reverse-biased diode accross the relay coil to snub any spikes when it drops, or use one of the new-fangled MOSFET devices.

You're best using a switching transistor, these switch hard on for a range of input voltages, a normal tranny conducts according to the base voltage, as in the motor speed circuit I referred to.

Put a reverse-biased diode accross the relay coil to snub any spikes when it drops, or use one of the new-fangled MOSFET devices.

live feed

i went into halfords and their sip no gas migs are live feed

Hi Dan,

Purely & simply because Screwfix ain't got a clue about welders!!

Live Torches went out AGES ago.

weldequip

i went into halfords and their sip no gas migs are live feed

Not all of the models? I thought they would all be non-live torches nowadays... avoid em, live torches are a real ball-ache to use, especially for beginers.

(you are also better with a gas machine if you intend doing thin car bodywork).

weldequip

(you are also better with a gas machine if you intend doing thin car bodywork).

weldequip

Workman, tools etc

Have i really just joined a forum? oh well. first and last post ever just to say.....read this in disbelief..... "a poor workman blames his tools".... .? oh yes. been welding for God knows how long, army taught and i've me been around the block since but believe me, if you need to weld, and you CAN weld. you make do! if you'd seen the ****e i started with, stop griping like a spoilt child and get on with it. all t'best. E.

Have i really just joined a forum? oh well. first and last post ever just to say.....read this in disbelief..... "a poor workman blames his tools".... .? oh yes. been welding for God knows how long, army taught and i've me been around the block since but believe me, if you need to weld, and you CAN weld. you make do! if you'd seen the ****e i started with, stop griping like a spoilt child and get on with it. all t'best. E.

rtbcomp

Moderator

- Messages

- 18,549

- Location

- Sheffield UK

Have i really just joined a forum? oh well. first and last post ever just to say.....read this in disbelief..... "a poor workman blames his tools".... .? oh yes. been welding for God knows how long, army taught and i've me been around the block since but believe me, if you need to weld, and you CAN weld. you make do! if you'd seen the ****e i started with, stop griping like a spoilt child and get on with it. all t'best. E.

I think that's a bit unfair, lots people on here are just starting out and learning on bad equipment is not the way to do it. I don't care how good you are you will not get good results with crap equipment, how many professional welders will choose Wolf over Milller and all the other top names?

Have i really just joined a forum? oh well. first and last post ever just to say.....read this in disbelief..... "a poor workman blames his tools".... .? oh yes. been welding for God knows how long, army taught and i've me been around the block since but believe me, if you need to weld, and you CAN weld. you make do! if you'd seen the ****e i started with, stop griping like a spoilt child and get on with it. all t'best. E.

disgruntiled ebay seller maybe

take a chill pill man

take a chill pill man seems to be wide spread on forums at the minute

seems to be wide spread on forums at the minute

again!!

Think im hooked....... WFA? anyroad. i weld mostly narrow boats in me spare time and permanent way in work (railway track) use SIP for marine work and MUREX (alumino-thermit) kit for work.... so ya never know i may be able to offer advice or ya could always tell me to **** off granddad! take it easy. E.

Think im hooked....... WFA? anyroad. i weld mostly narrow boats in me spare time and permanent way in work (railway track) use SIP for marine work and MUREX (alumino-thermit) kit for work.... so ya never know i may be able to offer advice or ya could always tell me to **** off granddad! take it easy. E.

nigelmercier

Member

- Messages

- 7

I've just bought the Wolf 140A from UKHS via eBay. I can confirm that the tip is NOT live until the trigger is pulled.

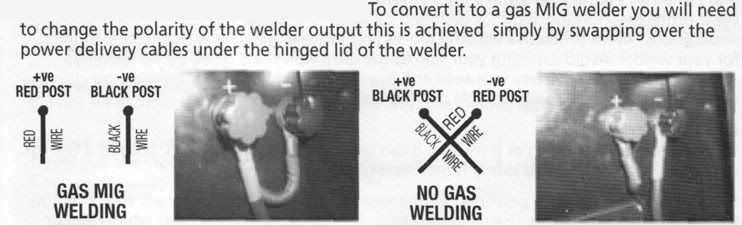

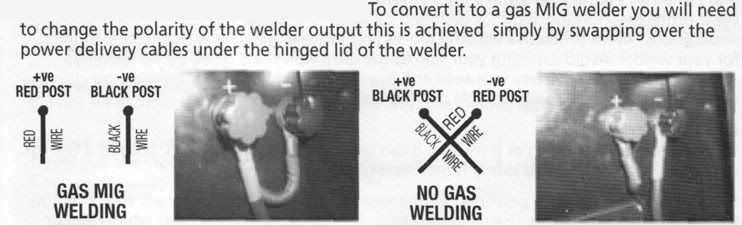

I do have one problem though, the manual is ambiguous regarding the delivery cables (on Page 5 if you have the same manual). Both of the diagrams show red wire to red post and black wire to black post, and the pictures don't help as they are not in colour, see below:

I do have one problem though, the manual is ambiguous regarding the delivery cables (on Page 5 if you have the same manual). Both of the diagrams show red wire to red post and black wire to black post, and the pictures don't help as they are not in colour, see below:

nigelmercier

Member

- Messages

- 7

DCEN is for flux core , work clamp would be +.

DCEP is for gas shielded wire work clamp would be -.

Robert

Hi Robert,

Sorry, but I don't understand. I appreciate that the clamp and tip swap polarity for the two modes, but I can't tell which lead goes to which.