- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,866

- Location

- East Yorkshire

- Messages

- 14,816

- Location

- UK

I needed to machine the bearing housing off a Munice SM420 gearbox. Most of thecasting is off centre by a long way. Needed a counter balance, I had a root about picked a lump up and plonked it on the faceplate. Amazingly it was bang on, a 2p on the h/stock didn't move

View attachment 222048

Whats the TP you have on there Shox - a wedge type?

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,866

- Location

- East Yorkshire

Whats the TP you have on there Shox - a wedge type?

Piston, not had any problems, tooling doesn't move and is repeatable

nick952

Member

- Messages

- 259

- Location

- Wrexham, N.Wales

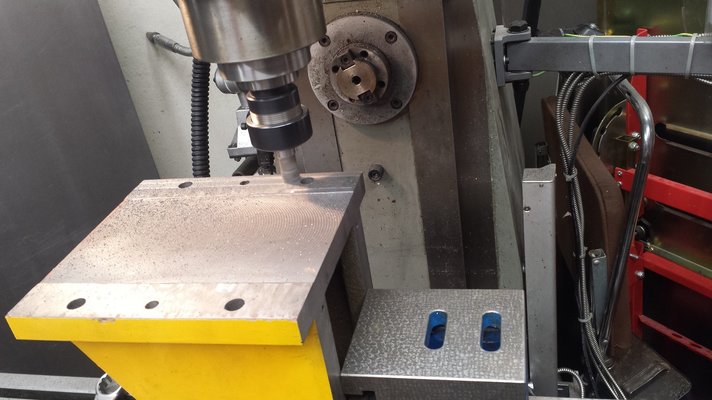

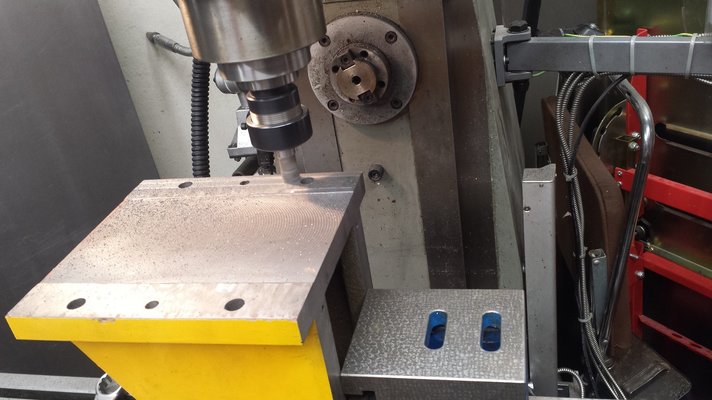

Currently reworking my POS Chinese Syil X5 CNC mill, to correct all the geometric errors.

After measuring the errors in the assembled machine, I set about removing the cosmetic scraping (that appears to have been done with a hammer and chisel, to hide the angle grinder bodging) and correct most of the error by re-machining the faces, in preparation for final alignment scraping.

After measuring the errors in the assembled machine, I set about removing the cosmetic scraping (that appears to have been done with a hammer and chisel, to hide the angle grinder bodging) and correct most of the error by re-machining the faces, in preparation for final alignment scraping.

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

I find it pretty interesting that yoy can mill a mill on a mill. This Is how they would make mills, and somehow get better accuracy each time, probably through scraping.

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

127T done, not perfect but very close, I think it moved on the Arbor slightly during a cut. Think I will do it again from the better material. It's noticeably louder than the 100t it replaced and rings quite a bit.

M16 X 2 thread cut to test it out...delighted I can finally cut metric threads. One more thing (mostly) scored off the project list.

M16 X 2 thread cut to test it out...delighted I can finally cut metric threads. One more thing (mostly) scored off the project list.

Agroshield

Member

- Messages

- 6,339

It's noticeably louder than the 100t it replaced and rings quite a bit.

Maybe glue a couple of pieces of flattened inner tube rubber to it with contact cement. Or car sound deadener if you have some. Self adhesive flashband possibly.

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

Maybe glue a couple of pieces of flattened inner tube rubber to it with contact cement. Or car sound deadener if you have some. Self adhesive flashband possibly.

I was thinking similar, need to see what I can scrounge up.

Agroshield

Member

- Messages

- 6,339

I wanted to make an adaptor but it needs a 1/2" bsp thread, 14 tpi 55 degree bsw. It seems my lathe can do it, but I only have 60 degree tools, close enough?

Have a look at this thread where the issue is extensively discussed:

https://www.mig-welding.co.uk/forum/threads/harrison-600-milling-machine.99320/

Just in case you are not aware, 15mm plumbing fittings are 1/2" BSP. So are old wash basin or sink taps.

slim_boy_fat

Member

- Messages

- 29,187

- Location

- Scottish Highlands

EDIT: Wrong thread, should be elsewhere.....

slim_boy_fat

Member

- Messages

- 29,187

- Location

- Scottish Highlands

They are wonderful when they jump inside your open neck shirt, sizzle away and brand your skin

You need one of these......

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

You need one of these......

I think I would prefer the branding