- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

scottmk1

Member

- Messages

- 1,975

- Location

- Scotland

Then that threaded rod infront of the cutter is just a stop and nothing to do with the spindle, not attached to rotating bits in any way..

Yes it's just an adjustable depth stop.

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

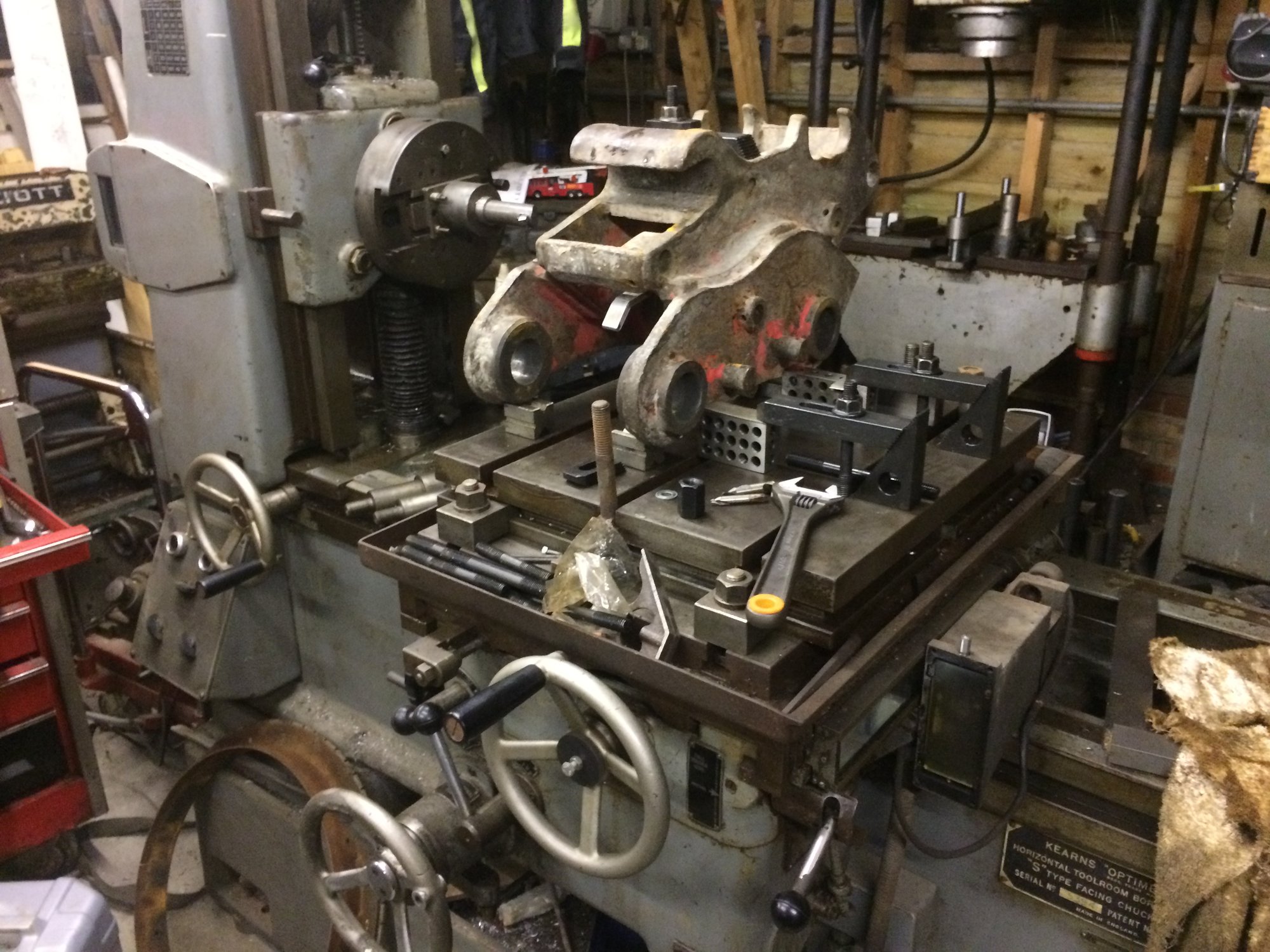

Bored a quick hitch on the baby kearns

zx9

Forum Supporter

- Messages

- 5,187

- Location

- South East London

What's that that you are making?Tough is tough but worth it.

View attachment 204295

Woody.v8

Blue gluer

- Messages

- 4,212

- Location

- staffs

Its a leaf spring for the stockcar, I needed to flatten off a hump in the back of the leaf so it fits nice on a pearch ,The weight savings welcome too!What's that that you are making?

zx9

Forum Supporter

- Messages

- 5,187

- Location

- South East London

Wow thanks for the info, I can see what it is now and appreciate how hard spring steel would be to mill.Its a leaf spring for the stockcar, I needed to flatten off a hump in the back of the leaf so it fits nice on a pearch ,The weight savings welcome too!

Woody.v8

Blue gluer

- Messages

- 4,212

- Location

- staffs

It's ok until you hit a "knotty" bit that is that hard it just wont cut .Funnily enough, it actually machines quite nicely. I have never had a problem machining hard material, it’s the soft, snotty, ropey stuff that is normally the one to mess you around

I have put some 35mm holes in another and killed a annular cutter in 4 holes! ,I've just ordered a carbide tipped one and hope that fairs better!

I hope so because I'm already at £8 per hole

Woody.v8

Blue gluer

- Messages

- 4,212

- Location

- staffs

I'm on the lookout for a cnc mill now as it would open up the world for me making prototype parts for the stockcar, I don't really know how to use one yet but I usually pick things up quickly.It’s not normally the material per say. It’s the cutter has lost its edge,you don’t push hard enough to get it to bite,it rubs,then lights the cutter up and work hardens the material in the blink of an eye. Duplex and Super duplex stainless steel also suffer from the same lack of sense of humour,they don’t like being tickled.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

The amount of fishermen who bring stainless parts in to me saying can I drill this for them with one of my stainless cutting drills because theirs are not cutting it. I try to explain to them that the drill itself doesn't matter, well within reason, and that it is their method that is to blame. It is a PITA because I then have to break out the carbide to get through their work hardened stainlessIt’s not normally the material per say. It’s the cutter has lost its edge,you don’t push hard enough to get it to bite,it rubs,then lights the cutter up and work hardens the material in the blink of an eye. Duplex and Super duplex stainless steel also suffer from the same lack of sense of humour,they don’t like being tickled.

zx9

Forum Supporter

- Messages

- 5,187

- Location

- South East London

To an extent I would agree to that, I suppose for the tools that are available to me the spectrum of soft and snotty - nice to turn - why did I even think this was a good idea? tends to turn to the bad idea side just after silver steel and well before the block of unknown I am currently trying to fashion into a modified fixed steady. Cue: Chatter, blunt HSS or chipped carbide embedded in the surface.Funnily enough, it actually machines quite nicely. I have never had a problem machining hard material, it’s the soft, snotty, ropey stuff that is normally the one to mess you around

Woody.v8

Blue gluer

- Messages

- 4,212

- Location

- staffs

I am interested, feel free to PM me a rough price to see if I can afford it , and if you have any pictures would be good.I might have exactly what you are looking for.

I have a bigger version of a Bridgeport made by King Rich. They are an old ,well regarded foundry/machine tool manufacturer in Taiwan, who manufacture machines for a lot of the well known brands. 5hp motor if I remember correctly. It’s got an ISO 40 spindle on it, you can use 40int tooling or bt40 tooling with a pullstud adaptor. It’s got a airdrawbar, so press the bottom and drop the tool out. Fitted with a two axis Prototrak cnc controller,with digital read out on all three axis’s. Powered ,non cnc rise and fall of the knee,all new bearings in there. . Very good way of bridging the gap between conventional and cnc milling. Can use it as a manual machine or cnc. Very versatile. Even though I have a 4 axis mill with 24 tool toolchanger and a 5 axis lathe with 22 tools, I wouldn’t be without this style of mill,( I have two of them, but need space!).

Programming is really easy,from bolthole patterns etc,the servos position the table,you manually drill once in position. Press the button and it moves to the next co ordinate. Milling has a couple of cycles,from straight lines to arcs, pockets to frames. Can machine any 2d profile you can draw. All spares still available.

The particular machine I want to get rid of,( which stupid as it may sound,is the better one of the two,but the other one has sentimental value to me), has had the Slideways reground,new turcite etc. Was the last job out of Slideway services shop last December when Brian Caddy retired. It’s been used about two hours since.Its a really nice,sturdy machine. Ideal for small batch work or prototype kind of work.

You are more than welcome to come and have a play. It’s all wired up,not hastily connected in the back of a machine dealers warehouse. For the right kind of money,I will let it go. Probably could find a bit of tooling for you as well,but with bt40 stuff being cheaper than R8,it’s not a huge outlay to get well tooled up.

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

With any material smaller cuts and slower feeds just wear your cutters out quicker!That’s it in a nutshell,the push hard ,bit. It’s the push hard bit where most people go wrong. Stainless doesn’t have a sense of humour and doesn’t respond well to being tickled, it’s very easy to rub it up the wrong way....

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Aye, I did a vid to demonstrate it for a friend.With any material smaller cuts and slower feeds just wear your cutters out quicker!

Can't recall the spindle speed but I think the DOC was 2mm and again can't recall the feed speeds but one was slow the other a bit faster

The difference is night and day.

Now have a sore thumb from turning the wheel too much!

Make yourself an adaptor to use a cordless drill to turn the wheel.

Spark plug

Member

- Messages

- 4,036

- Location

- Durham, England

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Always just slipped a piece of bronze bar between the toolpost and the part and used that, maybe one day I will do it properly and make up a tool with bearing