- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

iNf

Forum Supporter

- Messages

- 720

- Location

- Hereford, England

Definitely need fewer teeth for cutting that sort of depth. Those high tooth count saws are for shallow slots. Same sort of principle as a hacksaw blade, you wouldn't cut that deep/wide with a high tooth count blade. You need a 36 tooth or similar. Though they'll all wander if you do really deep.They are pretty grotty aren't they? Wasn't sure if it was just me, it usually is. Worth a try though to experiment with. Maybe one with fewer teeth would be better? I'm not spending any more money to find out.

oldbikedavey

Member

- Messages

- 1,986

- Location

- London, England

Only Allah is perfect ....its a 3 jaw self centering chuck none of them are totaly accurate

pawsnizzy

Forum Supporter

- Messages

- 906

- Location

- Derbyshire, UK

Didn't he make hexagonal wrenchesOnly Allah is perfect ....

oldbikedavey

Member

- Messages

- 1,986

- Location

- London, England

Only the geometry bit.Didn't he make hexagonal wrenches

The perfection is a dead giveaway....

What is it in the last photo?First slots on the mill, on any mill I'm going to get a dro, what's everyone's preference,and a bit of skimming

View attachment 453643 View attachment 453644 View attachment 453645

Agroshield

Member

- Messages

- 6,326

I tried to trepan it out but it made a terrible noise

A lot of that is becasue the object is thin-walled and bell-shaped. It vibrates and resonates in strange ways. You can sometimes mitigate this by extra support under the piece you are cutting (e.g. sacrificial plywood) or wrap the whole thing in a blanket.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I noticed the last week that the lathe was cutting out a bit, the whole building moves over time due to the action of the waves as my workshop lies between the sea wall and a burn and the water seeps through the sea wall into the burn and takes soil with it leaving voids under my workshop.

So today I chucked up a length of round bar and started doing some test cuts and adjusting the feet to compensate, saves having to do a semi finish cut to measure then programme a cut to remove any taper.

Cut length was just shy of 400mm

This was the measurements after adjusting, I can live with 0.002mm difference over 400mm. Sad thing is the next storm it will be out again

So today I chucked up a length of round bar and started doing some test cuts and adjusting the feet to compensate, saves having to do a semi finish cut to measure then programme a cut to remove any taper.

Cut length was just shy of 400mm

This was the measurements after adjusting, I can live with 0.002mm difference over 400mm. Sad thing is the next storm it will be out again

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

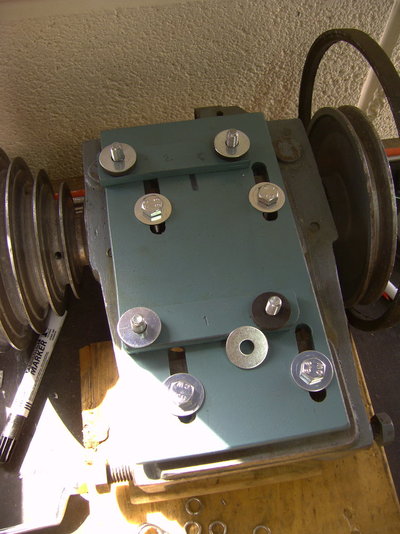

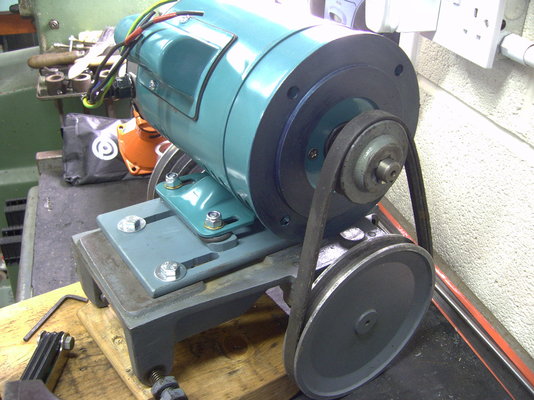

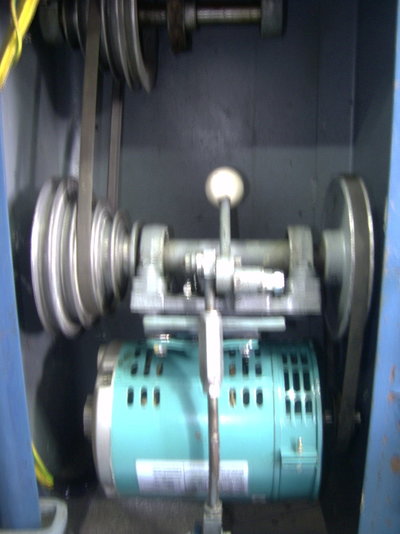

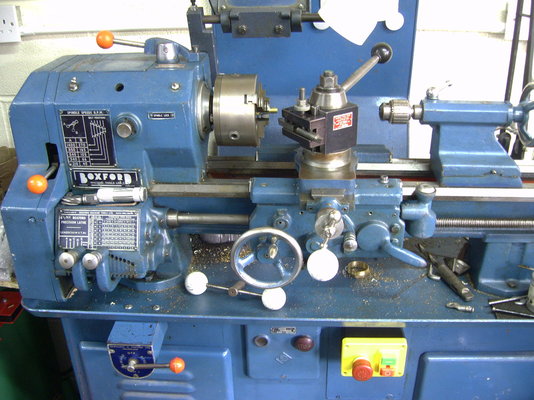

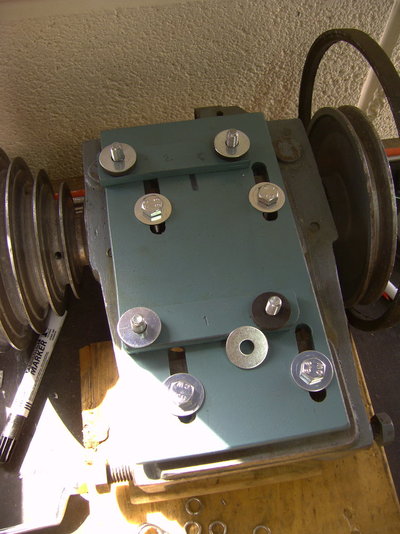

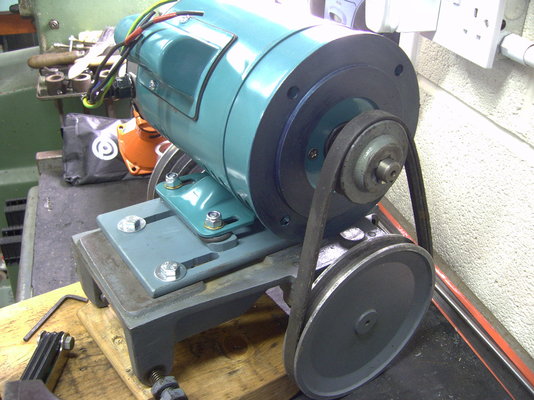

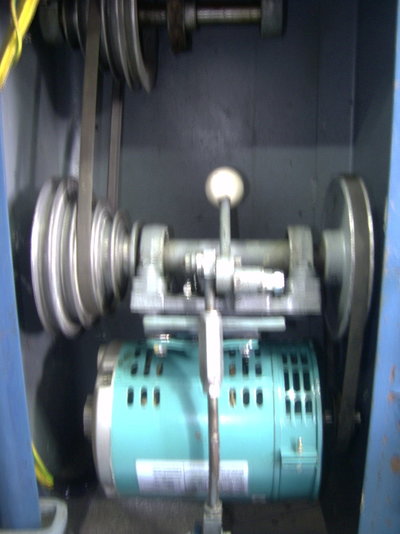

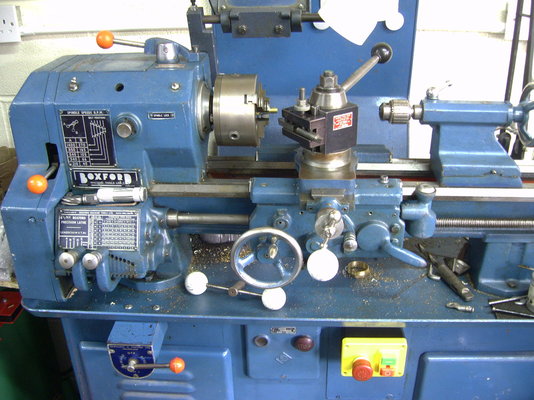

After five decades of service, the original motor in my Boxford lathe gave up the ghost, as they say. I bought a new 1/2 hp one, but as I understand it, motors nowadays are manufactured with both a foot and face mounting features. Well, the pulleys wouldn't line up, so I fabricated an offset adapter plate. Didn't have a sharp milling bit of the right size, so I drilled and used the die filer to cut the slots, cut some bolts for studs, then threaded them in and welded flush with the plate's base. A time consuming little project, but the lathe is up and running again.

.

.

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

Its slightly lighter than the colour on my Tom Senior mill, almost matches the shade on the Fobco drill press. Paint was from Aldi, and I've used it on several tools, like the vice in the photo.Ton Senior colour?

.

.

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

A little rainy day project for my nc750x bike. There have been a couple of videos showing a fix to change the slope angle on the seat to prevent sliding forward, which is an issue many have had. My solution was to cut and fit a couple of rubber walking stick feet on the existing bumpers to raise the front of the seat up about 20mm, and make an adapter bracket using the same bolts. So no permanent modification, and all is easily removed to put the seat back into stock configuration without damage.

A few photos....... To cut the rubber cane feet without messing them up, I slipped then over a scrap piece of 22mm copper pipe in a vice. This made it easy to tape a line around the circumference, and press hard to cut through without distorting. I then bent a U-shaped bracket to locate the tongue of the seat, and mark it to allow for two height adjustments before bending and drilling the ears; then gluing in a 20mm thick spacer which can be used either over, or under the new bracket. Once fitted and checked, a shot of paint and job done. The lighting in the last photo shows what looks like a large gap, but there isn't; its actually hardly noticeable.

The lighting in the last photo shows what looks like a large gap, but there isn't; its actually hardly noticeable.

.

A few photos....... To cut the rubber cane feet without messing them up, I slipped then over a scrap piece of 22mm copper pipe in a vice. This made it easy to tape a line around the circumference, and press hard to cut through without distorting. I then bent a U-shaped bracket to locate the tongue of the seat, and mark it to allow for two height adjustments before bending and drilling the ears; then gluing in a 20mm thick spacer which can be used either over, or under the new bracket. Once fitted and checked, a shot of paint and job done.

The lighting in the last photo shows what looks like a large gap, but there isn't; its actually hardly noticeable.

The lighting in the last photo shows what looks like a large gap, but there isn't; its actually hardly noticeable..

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

An afterthought.A little rainy day project for my nc750x bike. There have been a couple of videos showing a fix to change the slope angle on the seat to prevent sliding forward, which is an issue many have had. My solution was to cut and fit a couple of rubber walking stick feet on the existing bumpers to raise the front of the seat up about 20mm, and make an adapter bracket using the same bolts. So no permanent modification, and all is easily removed to put the seat back into stock configuration without damage.

A few photos....... To cut the rubber cane feet without messing them up, I slipped then over a scrap piece of 22mm copper pipe in a vice. This made it easy to tape a line around the circumference, and press hard to cut through without distorting. I then bent a U-shaped bracket to locate the tongue of the seat, and mark it to allow for two height adjustments before bending and drilling the ears; then gluing in a 20mm thick spacer which can be used either over, or under the new bracket. Once fitted and checked, a shot of paint and job done.The lighting in the last photo shows what looks like a large gap, but there isn't; its actually hardly noticeable.

.

View attachment 458133 View attachment 458134 View attachment 458135 View attachment 458136 View attachment 458137 View attachment 458138

I initially overlooked that changing the angle of the seat's slope would also raise it at the rear, where two elongated rubber bumpers supported the back end of the seat. To sort the issue, I covered a couple of blobs of "White Tack" in cling film, so it wouldn't stick, and positioned them over the rubber bumpers, then installed the seat and tightened the two retaining bolts. Removing the seat provided me with the flattened White Tack which I then measured. I found a strip of neoprene which I bought by mistake when ordering a sheet to make an extension for my front fender; and fortunately the strip was about the right thickness to fill the gap. I cut a couple of pieces to stick on the bumpers for support, and the job is done properly now. The seat fits snug.

E T

Member

- Messages

- 661

- Location

- Netherlands

I got myself some new indexable endmills.

two have a 20mm shank so I made another MT3 endmill holder for the mill from a old front output shaft from a LR serie 2a gearbox.

Less than 0.01mm runout on the endmill shank. I can live with that.

I'm still in doubt if I should cut down the shanks for a bit less stickout.

two have a 20mm shank so I made another MT3 endmill holder for the mill from a old front output shaft from a LR serie 2a gearbox.

Less than 0.01mm runout on the endmill shank. I can live with that.

I'm still in doubt if I should cut down the shanks for a bit less stickout.