- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

Found the O1, is a peice 73 x 43 x 25mm ok? I have a use for the 35mm offcut.

It'll be under 1kg, pm me a post label. If it stops raining I'll get it sent tomorrow afternoon.

PM sent

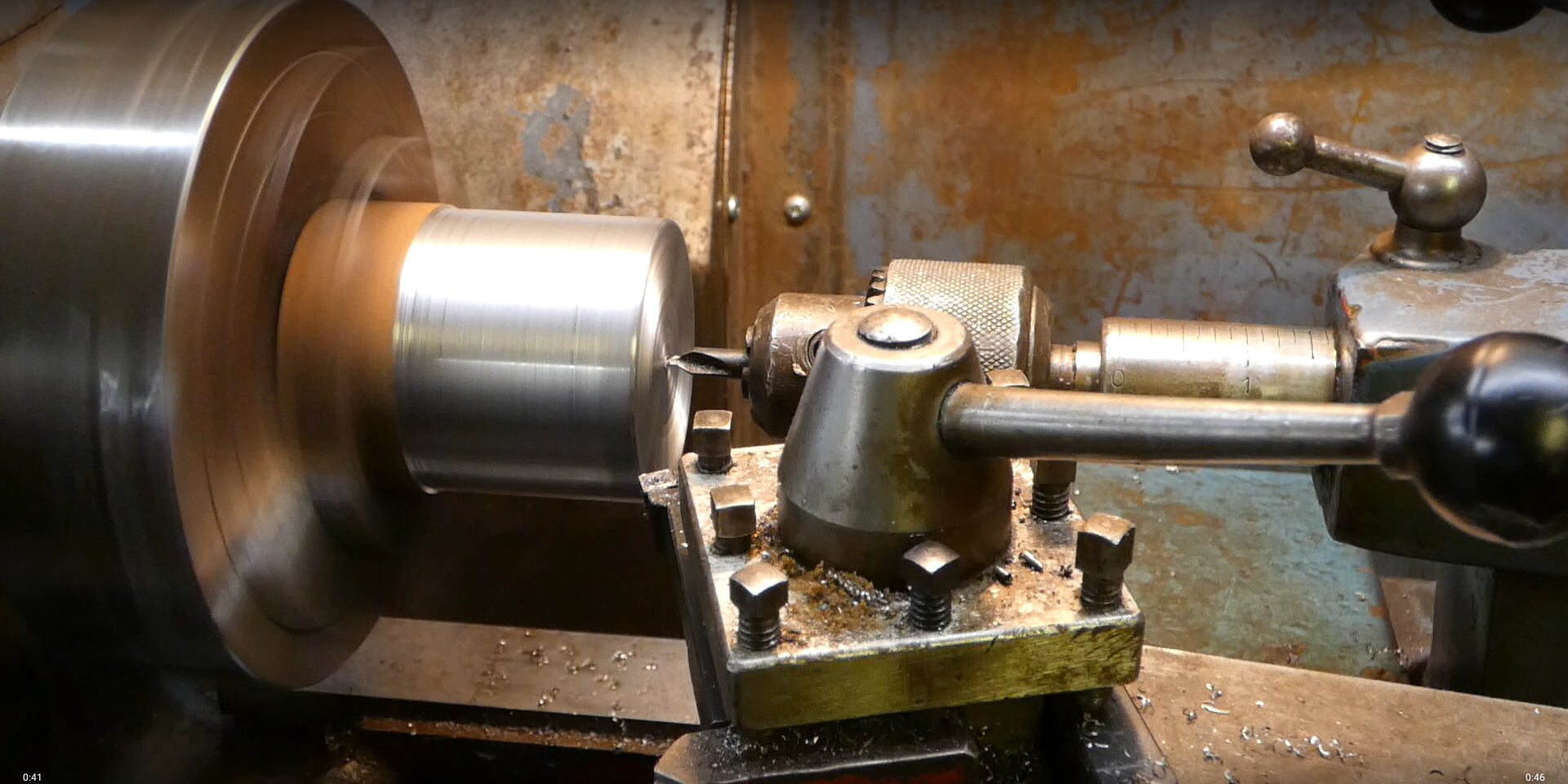

Right. This doesn't look like much, but today I have cut a taper into a piece of bar on the lathe. I've also cut a 3/16ths keyway slot on the mill, centre-drilled and tapped an internal M6 thread and finally cut an m12 nub on the other end to centre the piece for welding or brazing together tomorrow.

This tractor steering wheel has a taper in the centre. I tried measuring the major and minor diameters plus the length of the hole to calculate the taper angle. In practice, I didn't get anywhere close. I looked up common machine tapers on line to get a better idea and found an mt2 taper jammed in the orifice was a reasonably close but still a slack fit. I settled on a 1.4 degree taper and knocked the compound angle around on the lathe after each test cut and fit to get somewhere close.

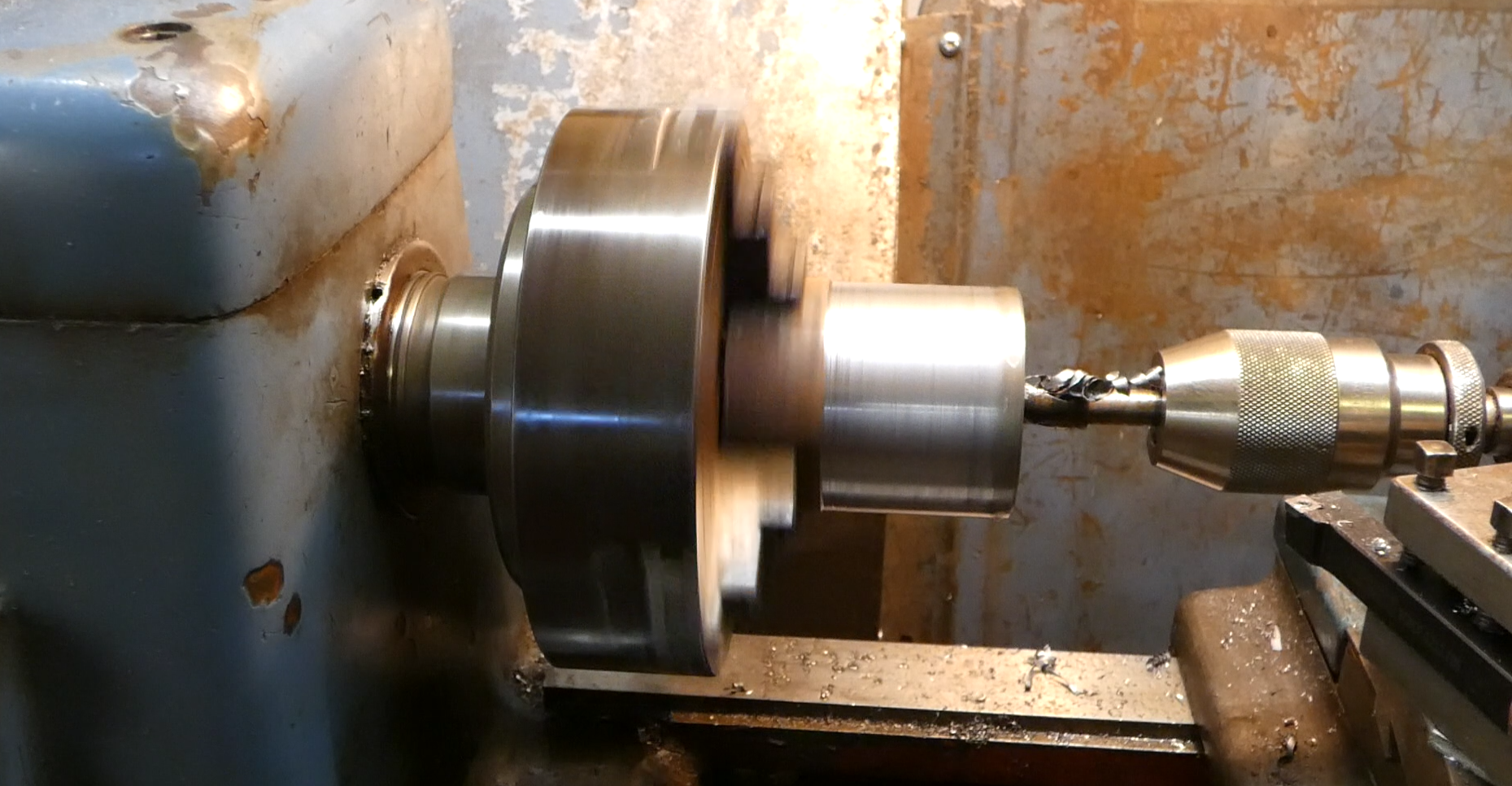

Looking good at this end.

There's a big chamfer at both sides of the steering wheel boss, hence the apparent gap below.

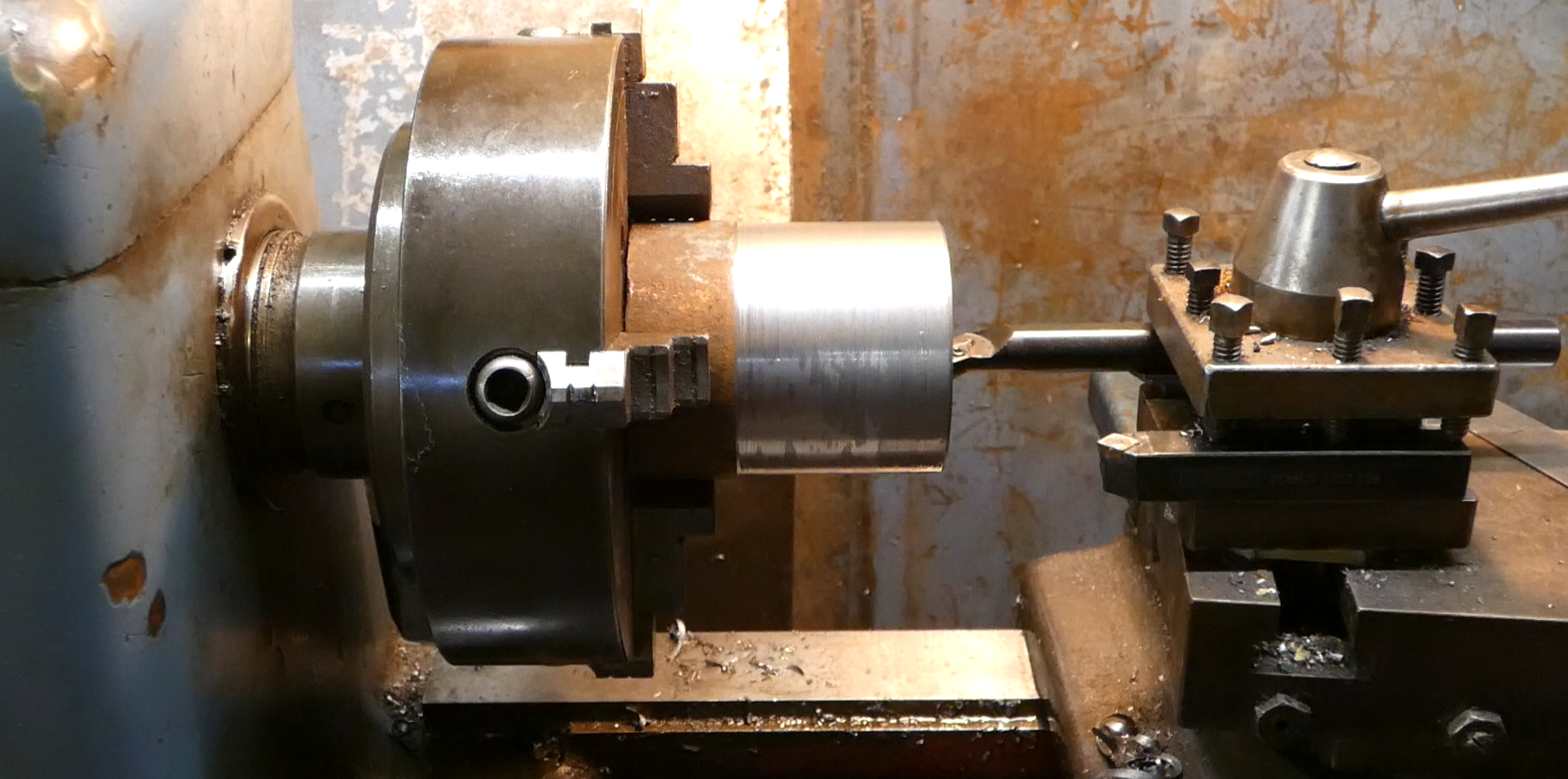

I've cut off the bent bar handle showing below and I'm looking to braze the spigot onto the round boss. My brazing is neater than my welding. It will make more sense once it is all together.

This tractor steering wheel has a taper in the centre. I tried measuring the major and minor diameters plus the length of the hole to calculate the taper angle. In practice, I didn't get anywhere close. I looked up common machine tapers on line to get a better idea and found an mt2 taper jammed in the orifice was a reasonably close but still a slack fit. I settled on a 1.4 degree taper and knocked the compound angle around on the lathe after each test cut and fit to get somewhere close.

Looking good at this end.

There's a big chamfer at both sides of the steering wheel boss, hence the apparent gap below.

I've cut off the bent bar handle showing below and I'm looking to braze the spigot onto the round boss. My brazing is neater than my welding. It will make more sense once it is all together.

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

Replacement wheel for my belt grinder drive wheel which cracked. JEI wanted £340 for a new plastic one! Spent £100 on the lump of ally and about 8 hours of my time.

View attachment 342123

I Like the key cutting on the lathe , just a bit of HSS there and back and forth action? .

Munkul

Jack of some trades, Master of none

- Messages

- 7,748

- Location

- Cumbria

Just some mild steelI Like the key cutting on the lathe , just a bit of HSS there and back and forth action? .

it's a bit rough on the lathe saddle though even for aluminium, i wouldn't want to cut steel that way.

it's a bit rough on the lathe saddle though even for aluminium, i wouldn't want to cut steel that way.Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

Ah smart then you only cut the edges into squares rather than remove all material, Bit like when you drill a hole and sit chuffing away with a file to try and square it up.A bit of a tweak with the cutting and relief angles would improve that a lot. What you can also do is turn a spigot to go into the bore,then drill a suitable sized hole half in the pulley,half in the spigot. Makes it a lot easier to get the keyway in as alot of material is removed before you start slotting

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I usually drill the hole before I bore the centre, or I used to before I had broaches and BFHA bit of a tweak with the cutting and relief angles would improve that a lot. What you can also do is turn a spigot to go into the bore,then drill a suitable sized hole half in the pulley,half in the spigot. Makes it a lot easier to get the keyway in as alot of material is removed before you start slotting

My Old Landy

Engineering Mayhem

- Messages

- 3,506

- Location

- North Lincs

I did a bit more on my ER32 chuck. I managed to break a centre drill  which is something I have not done in years! I even caught it on video!

which is something I have not done in years! I even caught it on video!

which is something I have not done in years! I even caught it on video!

which is something I have not done in years! I even caught it on video!Seadog

Save the planet. It's the only one with rum!

- Messages

- 13,005

- Location

- NE London - UK

I did tge same last week, I can't remember when I last broke one either. Whacked a carbide end mill in the chuck and soon had it sorted.I did a bit more on my ER32 chuck. I managed to break a centre drillwhich is something I have not done in years! I even caught it on video!

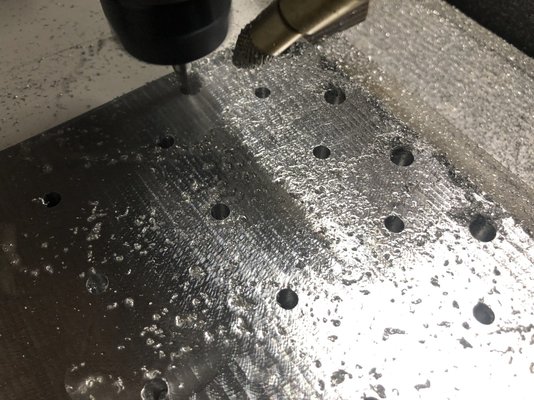

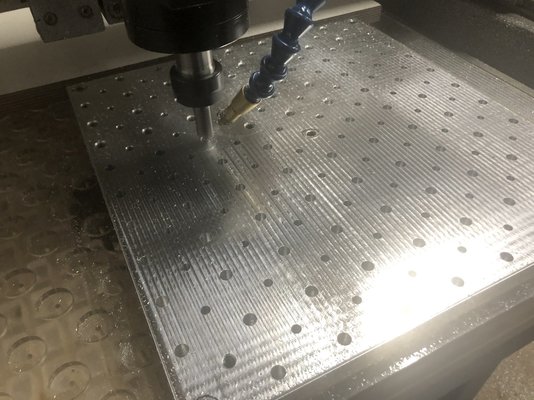

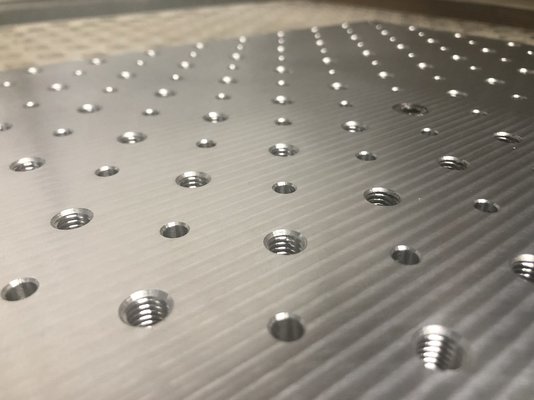

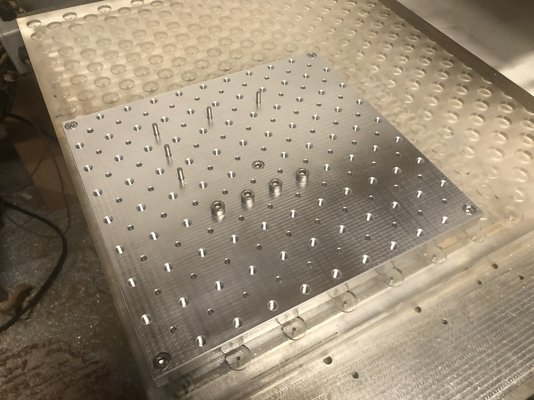

View attachment 344285View attachment 344284

View attachment 344283

Tornado220M

Banned

- Messages

- 35

- Location

- UK, Midlands

They are for CNC, the major difference is that a CNC machine can push the edge in to the work a lot better than a manual lathe can, also try and get a bigger chip as the bigger the chip the more heat it takes away therefore the less coolant you lose and the more stable the part, better surface finish etc.Remember those speed and feed tables are usually generated specifically for CNC production speeds. As Hood says, you don't need speed necessarily to break chips, just an adequate DOC and good feed rate for the insert...

Tornado220M

Banned

- Messages

- 35

- Location

- UK, Midlands

Are you using a HAAS ?