You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Very first steps! Haven't even turned the thing on yet.

- Thread starter PaulaT

- Start date

PaulaT

Member

- Messages

- 32

- Location

- London UK

When you have it all set up. get some scrap, clean it up and practice practice, practice. When you get fed up, practice some more. That's what I'm still doing.

Should i practice with the flux core or with the gas? I'm thinking it's cheaper to practice with flux core?

gaz1

Member

- Messages

- 20,374

- Location

- westyorkshire

with gasless wire it apears hotter and is bright

play around with it get used to being close to the material your welding about 5/10mm away from your work try getting constant at that use the other hand as support

gas wire is different you will end up practicing with that wire when you get it

play around with it get used to being close to the material your welding about 5/10mm away from your work try getting constant at that use the other hand as support

gas wire is different you will end up practicing with that wire when you get it

you are right thinking it's cheaper with gasless wire. But results will be different for both as already explained. So you will still need to practice on both.Should i practice with the flux core or with the gas? I'm thinking it's cheaper to practice with flux core?

PaulaT

Member

- Messages

- 32

- Location

- London UK

Find a local engineering company or fabricator and ask if you can raid their scrap bin. I have found such a company and donate to the "Bun Fund" when I visit, keeps them happy and I get all the off cuts I need to practice on.

I can ask they guys at the place that have the SGS gas. They are a radiator refurb place and have a yard full of stuff.

Welcome to the Forum.

I also have an Uptime MIG160 welder. There is a review here:

https://www.mig-welding.co.uk/forum...igbt-160-amp-mig-welder-mma-euro-torch.88278/

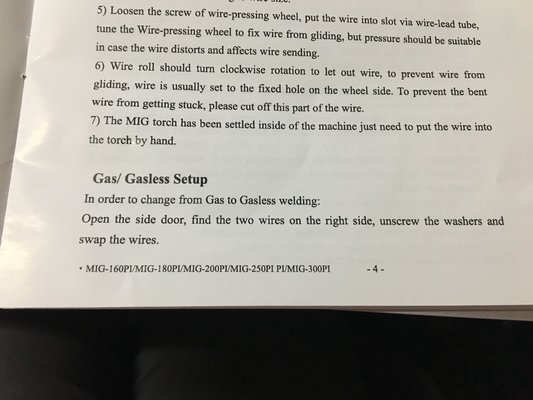

The welder arrived set up for solid wire + gas. The internal wire covered with white heatproof sleeving is the feed in to the Euro torch socket. It was bolted to the lower ( Positive ) Dinse socket. The Earth lead would then be plugged in to the upper ( Negative ) socket.

To convert to gasless wire, the internal white cable has to be moved to the upper ( Negative ) socket, and the Dinse plug on the Earth clamp lead plugged in to the lower ( Positive ) socket on the front panel.

I have used both solid .8mm wire with gas and flux-cored gasless 0.9mm wire with the same 0.8mm tip and roller, it seems to feed OK for both.

Flux-cored gasless wire is best for welding outside ( where shielding gas may get blown away by wind ) and some people find it makes overhead welding easier.

I also have an Uptime MIG160 welder. There is a review here:

https://www.mig-welding.co.uk/forum...igbt-160-amp-mig-welder-mma-euro-torch.88278/

The welder arrived set up for solid wire + gas. The internal wire covered with white heatproof sleeving is the feed in to the Euro torch socket. It was bolted to the lower ( Positive ) Dinse socket. The Earth lead would then be plugged in to the upper ( Negative ) socket.

To convert to gasless wire, the internal white cable has to be moved to the upper ( Negative ) socket, and the Dinse plug on the Earth clamp lead plugged in to the lower ( Positive ) socket on the front panel.

I have used both solid .8mm wire with gas and flux-cored gasless 0.9mm wire with the same 0.8mm tip and roller, it seems to feed OK for both.

Flux-cored gasless wire is best for welding outside ( where shielding gas may get blown away by wind ) and some people find it makes overhead welding easier.

stuvy

Member

- Messages

- 9,202

Find a local engineering company or fabricator and ask if you can raid their scrap bin. I have found such a company and donate to the "Bun Fund" when I visit, keeps them happy and I get all the off cuts I need to practice on.

You will learn more in 3minutes with someone that knows what there doing than in 3 years of guessing what’s going on.

Start as you mean to go on as gasless isn’t that good especially for doing any bodywork as youl end up blowing holes in the metal

Welcome to the forum and a world of burns where you didn’t expect them

arther dailey

Member

- Messages

- 6,936

- Location

- England

if your welding with gas ,pracctice with gas

ajlelectronics

Member

- Messages

- 11,088

- Location

- Gloucester, England

Welcome to the forum and a world of burns where you didn’t expect them

Oh yes! I would post a photo, but it would frighten the natives!

PaulaT

Member

- Messages

- 32

- Location

- London UK

Welcome to the Forum.

I also have an Uptime MIG160 welder. There is a review here:

https://www.mig-welding.co.uk/forum...igbt-160-amp-mig-welder-mma-euro-torch.88278/

The welder arrived set up for solid wire + gas. The internal wire covered with white heatproof sleeving is the feed in to the Euro torch socket. It was bolted to the lower ( Positive ) Dinse socket. The Earth lead would then be plugged in to the upper ( Negative ) socket.

To convert to gasless wire, the internal white cable has to be moved to the upper ( Negative ) socket, and the Dinse plug on the Earth clamp lead plugged in to the lower ( Positive ) socket on the front panel.

I have used both solid .8mm wire with gas and flux-cored gasless 0.9mm wire with the same 0.8mm tip and roller, it seems to feed OK for both.

Flux-cored gasless wire is best for welding outside ( where shielding gas may get blown away by wind ) and some people find it makes overhead welding easier.

Ok great. Got it. Move the white one up and plug the earth clamp into the positive (lower) socket.

there are 3 wires not 2.

That's right, the manual differs from the machine. The two thick black wires are the actual power, supplied from the main inverter board, and bolted to the rear of the two Dinse sockets. The upper black cable is negative, the lower one is positive, and the Dinse sockets are labelled on the front panel in that way.

As shipped, the setup is for solid wire plus gas, and so the white wire to the Euro socket picks up from the positive.

PaulaT

Member

- Messages

- 32

- Location

- London UK

Great.That's right, the manual differs from the machine. The two thick black wires are the actual power, supplied from the main inverter board, and bolted to the rear of the two Dinse sockets. The upper black cable is negative, the lower one is positive, and the Dinse sockets are labelled on the front panel in that way.

As shipped, the setup is for solid wire plus gas, and so the white wire to the Euro socket picks up from the positive.

Thanks, that’s perfectly clear.

jinjahbiscuit

Member

- Messages

- 347

Better than my first attempts

PaulaT

Member

- Messages

- 32

- Location

- London UK

Practice practice practice!

Still using Flux core. Very handy to find a wing of a car on the street. I think i'm getting it.

There's a big difference between doing a beed and joining metal together. It's 1.5mm steel I think, so i was blowing massive holes in it at the start!

Any tips welcome. I found seeing what you are doing the biggest challenge.

Still using Flux core. Very handy to find a wing of a car on the street. I think i'm getting it.

There's a big difference between doing a beed and joining metal together. It's 1.5mm steel I think, so i was blowing massive holes in it at the start!

Any tips welcome. I found seeing what you are doing the biggest challenge.

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

I think i'm getting it.

Indeed you are, most of those look better than my efforts.

What does the reverse of the panel look like?

What does the reverse of the panel look like?