This was found many years ago when BMC nitrided the en40 mini cranks - they grew!Make a jig to hold gears at correct centres and use non-charging lapping paste to polish them back a little.

You can run the pair with a electric drill.

- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tos FN22 milling machine (Deckel clone)

- Thread starter Pete.

- Start date

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

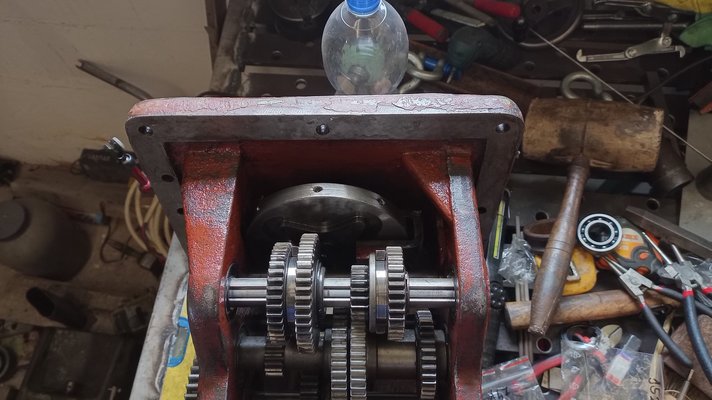

Its alive!

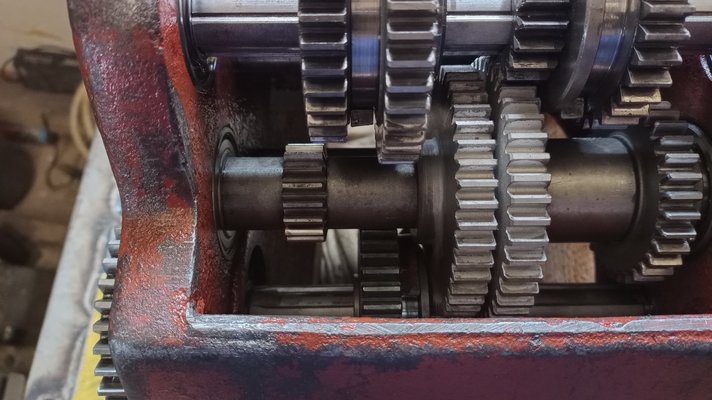

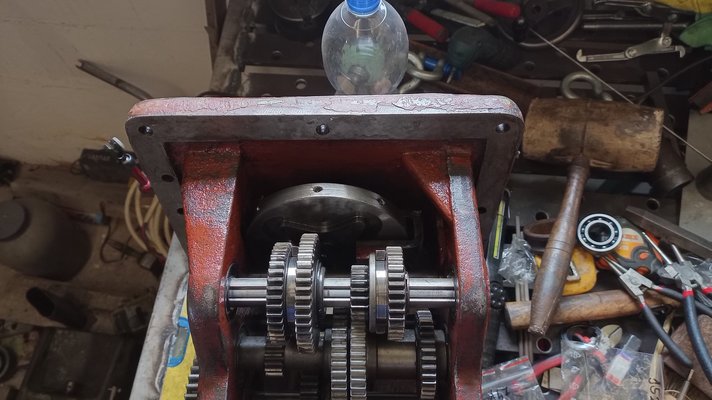

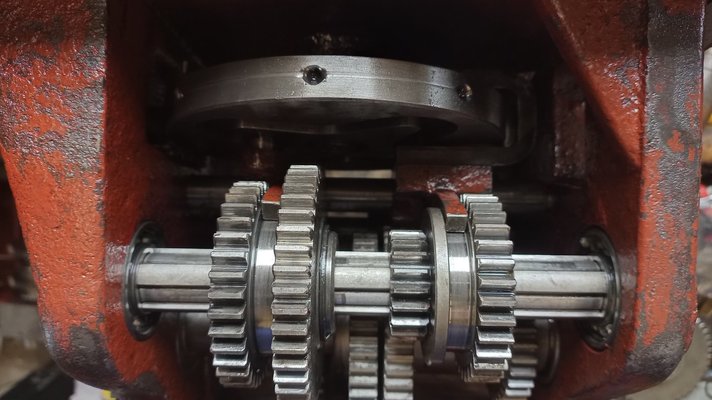

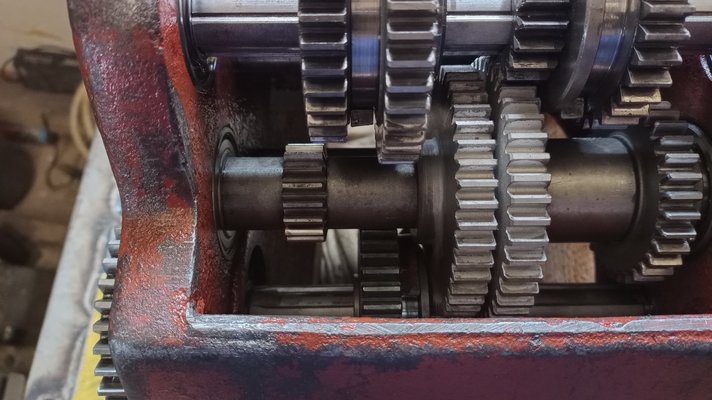

I managed to assemble the gearbox, then i put it back to the frame. It was not an easy job!

@Pete. , If the time arrives when you put your machine together, an advice for the gearbox installment:

There is a ~15 mm hole in the center of the casting against the speed selector. If you put a bar into it, it gives an exellent grip to tilt the assembly in place. I did it all by myself, but if you can, invite someone for two extra hand.

Conclusion:

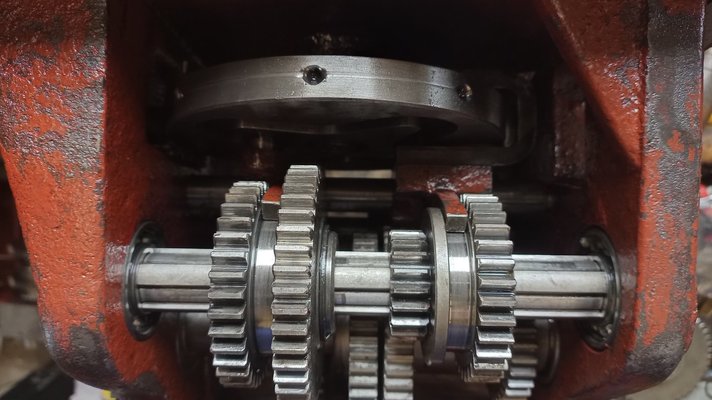

The gears are OK-ish, the tooth gap should be bigger. As all the errors sum up, there is a point when the gears slightly jam up, then free again.

I did a dry testrun to get all the dirt from the surfaces scraped off. Then I filled the space up with oil. The jamming can not be felt with hand, but the new gears can be heard:

I managed to assemble the gearbox, then i put it back to the frame. It was not an easy job!

@Pete. , If the time arrives when you put your machine together, an advice for the gearbox installment:

There is a ~15 mm hole in the center of the casting against the speed selector. If you put a bar into it, it gives an exellent grip to tilt the assembly in place. I did it all by myself, but if you can, invite someone for two extra hand.

Conclusion:

The gears are OK-ish, the tooth gap should be bigger. As all the errors sum up, there is a point when the gears slightly jam up, then free again.

I did a dry testrun to get all the dirt from the surfaces scraped off. Then I filled the space up with oil. The jamming can not be felt with hand, but the new gears can be heard:

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

Doesn't sound too bad I doubt if it's any more noisy than mine at full speed. Those spur gear trains are always going to be noisy.

Do you have a feed gearbox in yours, in the base of the machine?

Thanks, it had a worse voice back then, you can imagine.

I'm happy how it turned out.

Yes, i have one, with the reversing gearset on the back. Right now the belt is not installed for the feed gearbox.

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

By the way, i took some photos about the replaced X nut..Thanks, it had a worse voice back then, you can imagine.

I'm happy how it turned out.

Yes, i have one, with the reversing gearset on the back. Right now the belt is not installed for the feed gearbox.

I will tap an M36x1,5 thread through the whole nut, then glue a bronze bushing into it, to save a lot of that precious metal.

The adjusting part will be bronze aswell, as in the original design.

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

Heat treatment makes thing get thicker

Sensible way to ht gears is to use induction on just the teeth

Sensible way to ht gears is to use induction on just the teeth

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

Yep, as I experienced now..Heat treatment makes thing get thicker

Sensible way to ht gears is to use induction on just the teeth

The base technology that I followed said that the dimensions will not be affected by the heat threatment.

I used 42CrMo4+Qt base material, because it is available at my favourite store at a bearable price. This material has good mechanical properties, and can be machined really good. This only needs a nitride coating on top, fo fullfil all the requirements I need.

Other solution would be a C45 material with induction hardenig, or use 16MnCr5, then carbonize the furface, then quenching and tempering. Due to quenching, the dimensions woud be affected, and the tooth would need to be grinded to final dimension.

The main problem, that I have no contact to a tooth grinding factory, so it would be more money to grind them, than start the whole process from the beginning, and mill the tooth with bigger tolerances.

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

Yes, i have one, with the reversing gearset on the back. Right now the belt is not installed for the feed gearbox.

What do you mean, reversing gearset? Does your feed gearbox have a rod with a round knob coming out the rear? I have seen photos of them but mine is not like that.

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

Yes, thats what I mentioned.What do you mean, reversing gearset? Does your feed gearbox have a rod with a round knob coming out the rear? I have seen photos of them but mine is not like that.

There is an extra gearbox under the pulley. With the knob, I can reverse the feed direction if i need.

I plan to clean that gearbox also and machine a new rod because mine is quite bent and damaged. If you need pictures of this gearbox, I can make some next weekend.

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

I have the gearbox which is in good condition apart from a couple of leaking seals, but it is non-reversing although it does seem to have and extra 'lump' behind the pulley. I'm pretty sure that the machine doesn't feed when the main motor is in reverse, so I guess that is why the gearbox has a reverser.

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

Yes, that lump is where the reversing gear is in the setup.I have the gearbox which is in good condition apart from a couple of leaking seals, but it is non-reversing although it does seem to have and extra 'lump' behind the pulley. I'm pretty sure that the machine doesn't feed when the main motor is in reverse, so I guess that is why the gearbox has a reverser.

The kinematics of the machine contains a kind of ratchet mechanism, as you saw, at the direction selectors on each axis. If you need to rotate the spindle the opposite direction as usual, (eg. boring head operations) the directions off the feeds will be reversed too. In that case, your feeds will not functional, as the ratchet mechanism will push back the selector lever to neutral.

Thats why there is a reverser on the feed gearbox also, as the reversed spindle needs reversed feed too. The spindle reversed electrically, but because the gearbox is "hardwired" to the main motor, it needs a reverser gearset, to change its direction back to the "normal".

Oh, how strange. Is the Deckel like this too does anyone know?In that case, your feeds will not functional, as the ratchet mechanism will push back the selector lever to neutral.

My Aciera has a separate motor for feeds so is independent of the direction of the main spindle.

Is there room for you to fit a separate motor @Pete. ?

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

The "ratchet" mechanism looks like this in all axis:Oh, how strange. Is the Deckel like this too does anyone know?

My Aciera has a separate motor for feeds so is independent of the direction of the main spindle.

Is there room for you to fit a separate motor @Pete. ?

The power can be only delivered through in one direction, otherwise the center piece lifted back to neutral.

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

I could fit a separate motor but first I want to look at this gearbox just in case there's something I've missed. Using a separate motor would carry the benefit that the main motor need not be running when using the high speed head just so you can have powered feeds.

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

How can I send you PM through this forum, so we can discuss the details about the electrical components, you mentioned?By the way @paradipiro do you need any of the electrical components from the switch cabinets? I am not using the contactors from mine and I had agreed to donate them to a guy as spares but he's in Russia so that's not an option now.

It"s not urgent, I ain't finish the mechanical part in the next month..

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

Probably because you are a new member...