You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This is a cry for help!

- Thread starter jimmypolo

- Start date

BrokenBiker

Member

- Messages

- 12,922

- Location

- Newport, South Wales

those welds dont look too bad. the real test is when you grind them back flat but realistically, any panel you weld is going to need at least a litte bit of filler before paint to get a good finish.

a reasonable test of your welds now yould be to cut a section out and bend it along the joint, see if the welds hold up or not. keep bending it back adn forth. ideally it wasnts to break outside the weld

a reasonable test of your welds now yould be to cut a section out and bend it along the joint, see if the welds hold up or not. keep bending it back adn forth. ideally it wasnts to break outside the weld

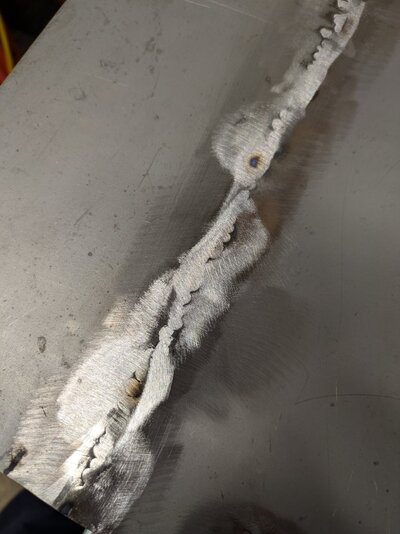

So bending didn't break it. I hammered it flat again and then hammered the line of the weld over a piece of H beam (anvil) to bend it and it came apart like this. 3 little sections where I hadn't put any weld down but other than that it's come apart on the outside of the lone of weld. Is that a good thing?

BrokenBiker

Member

- Messages

- 12,922

- Location

- Newport, South Wales

that break has happened around the welds, not through the welds which is a good sign. those welds are 'strogner' than the parent material so from a structural point of view, they are fine.So bending didn't break it. I hammered it flat again and then hammered the line of the weld over a piece of H beam (anvil) to bend it and it came apart like this. 3 little sections where I hadn't put any weld down but other than that it's come apart on the outside of the lone of weld. Is that a good thing?

now, a little exercise you can do it to tack every 25mm apart, let it cool then pick a random tack, weld to the next one with a series of overlapping tacks. then move to a different area and do the same, continue until its full...the idea is to keep the heat down buy only welding a small are then mving to a cold part and weld that to give the previous weld time to cool.

overlap your taks buy about half and when you grind back you should end up with a seamless weld and virtaully no distortion (i say virtually becasue you are welding sheet that is just free to move, on a car you have the rest of the fixed panel helping to reduce distortion to an extent)

Section about 440mm. I've ground off the front first with a black and decker powerfile (as recommended on here somewhere) then with a flap disc. There's one section where I've missed a couple of tacks but it looks (to me) as if I've stuck two bits of thin metal together

BrokenBiker

Member

- Messages

- 12,922

- Location

- Newport, South Wales

looks good to me. finishing technique will come with practice...i like to use a flap dic for all of it, very light pressure, let the disc do the work and then i can focus on keeping it level so i dont chew into the parent metal, then when its pretty much there i change to a sander with somehting like a 240 grit disc and blend it with that, then go over it with a poly disc or a prep pad to key it for any filler or primer