You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This is a cry for help!

- Thread starter jimmypolo

- Start date

I've had the steel for years so I can't remember what it is or where I got it from. It is completely rust free though so (from what I've read) it probably is zintec. I'll maybe give it quick once over with a flap disc and see it that helps. Cheers

BrokenBiker

Member

- Messages

- 12,922

- Location

- Newport, South Wales

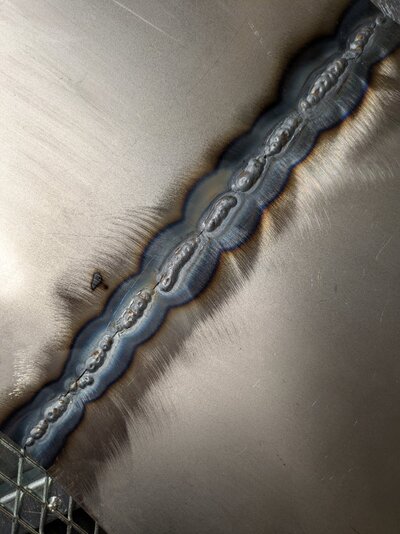

Looks like the results of welding galvanised so quite possibly zintec

It looks horrific but I think I've made some progress. Penetration isn't very good and you can see the joint on the pictures where I've ground off the weld (zoomed right in). But it stayed solid when I bent the steel to check the strength (unlike a previous attempt in one of the pics) I ground the coating off to bare shiny metal and I'm fairly happy that I MAY eventually be able to fix my car

-

PXL_20250815_115740763.jpg198.1 KB · Views: 73

PXL_20250815_115740763.jpg198.1 KB · Views: 73 -

PXL_20250815_120859148.jpg120.4 KB · Views: 73

PXL_20250815_120859148.jpg120.4 KB · Views: 73 -

PXL_20250815_120834102.jpg134.4 KB · Views: 56

PXL_20250815_120834102.jpg134.4 KB · Views: 56 -

PXL_20250815_120813234.jpg146.3 KB · Views: 63

PXL_20250815_120813234.jpg146.3 KB · Views: 63 -

PXL_20250815_115733681.jpg163.4 KB · Views: 69

PXL_20250815_115733681.jpg163.4 KB · Views: 69 -

PXL_20250815_115724439.jpg203.1 KB · Views: 65

PXL_20250815_115724439.jpg203.1 KB · Views: 65 -

PXL_20250815_121228539.jpg158.7 KB · Views: 73

PXL_20250815_121228539.jpg158.7 KB · Views: 73

Morris

Forum Supporter

- Messages

- 2,256

- Location

- Northamptonshire.

That's not bad for a beginner imo. Penetration is ok. It's certainly better than a lot of MOT welding I've seen.Front/back/profile

Trigger on for a little longer so I got penetration but I think I rushed too much so it's far from straight....

Getting good looking welds on thin sheet takes practice, the "long tack" technique doesn't help.

Yes I was using my left hand to steady my trigger hard. I think I need to take my time to get the wire on the joint properly. I was also trying to ignore light coming in from behind my head (round my mask) I think I saw a post on here somewhere about wearing a hoodie or having some kind of leather neck cover to cut out light?And you using both hands? One for trigger, one near the shroud to direct and steady.

I was also trying to lay a series of tack welds (maybe 4 at a time) and I think I strayed off line a bit

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,435

- Location

- Sevenoaks, UK

I found a peashooter invaluable for getting the gas flow correct. Just disengage the wire feed. Then hold the peashooter upright with the torch pressed up against the rubber base. Pull the trigger then adjust the flow back at the regulator on the bottle.

spaffmonkey

Forum Supporter

- Messages

- 888

- Location

- Northampton

Jumping in a bit late but your welding is coming along now. It takes time. I started with a lesson from a fellow member about 17 years ago then also did a night cause and northampton college before going into welding full time and several years later starting up my own business 8 years ago repairing narrowboats but still weld up the odd car.

Looking at your last picture where the metal looks distorted. To prevent that leave a 1mm gap between the sheets. Mig welding you are adding extra metal into the picture and it needs somewhere to go. also when leaving a small gap as the welds contract back they pull tight making for a better structure.

Looking at your last picture where the metal looks distorted. To prevent that leave a 1mm gap between the sheets. Mig welding you are adding extra metal into the picture and it needs somewhere to go. also when leaving a small gap as the welds contract back they pull tight making for a better structure.

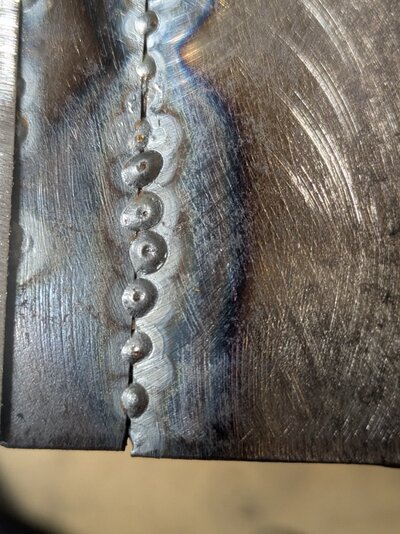

More practice today. 18ga steel, 0.8 wire, gas set to 15lt/min. Welder settings in pic 4

Think I've got decent penetration and ive been taking my time. A few tack welds first then short runs of 20-30 mm at a time. I must have put too much heat in as the metal is not flat.

I've been snipping the end of the wire off at the end of each 20mm of welding as there is a ball on the end of the wire. It also seems very short (close to the end of the shroud)? Also it doesn't strike an arc very well at the start of each section.

One other thing. It's approx 245 mm and it's taken me about half an hour to weld up waiting for it to cool so it doesn't distort. Which it has anyway. Is that normal? Just concerned that by the time I've practiced enough to start on my car we may all be using some other form of transport altogether......

Think I've got decent penetration and ive been taking my time. A few tack welds first then short runs of 20-30 mm at a time. I must have put too much heat in as the metal is not flat.

I've been snipping the end of the wire off at the end of each 20mm of welding as there is a ball on the end of the wire. It also seems very short (close to the end of the shroud)? Also it doesn't strike an arc very well at the start of each section.

One other thing. It's approx 245 mm and it's taken me about half an hour to weld up waiting for it to cool so it doesn't distort. Which it has anyway. Is that normal? Just concerned that by the time I've practiced enough to start on my car we may all be using some other form of transport altogether......

Misterg

Member

- Messages

- 1,706

- Location

- North Wales

Those runs are much too long to avoid distortion on 1.2mm steel. The whole thing needs to be a series of short, overlapping tacks: 2-3mm, not 20-30mm. Even then, you need to space them out, let it cool, and be lucky!A few tack welds first then short runs of 20-30 mm at a time. I must have put too much heat in as the metal is not flat.