You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Tupers

Member

- Messages

- 1,005

Is this for the same purpose? A school, iirc?[if not, just ignore my failing memory....

]

Yep the very same.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,495

- Location

- France, Brittany.

Very similar to @The_Yellow_Ardvark, I built a bench under my daughters IKEA bed.

Ate a huge quantity of homemade chicken and mushroom pie and chips. And did drawing with my daughter.

A quality sunday!

Ate a huge quantity of homemade chicken and mushroom pie and chips. And did drawing with my daughter.

A quality sunday!

henry Kadzielski

Member

- Messages

- 1,209

- Location

- Australia Wollongong

You have demanding customers.

Well @slim_boy_fat to his credit he did say please (the first time that I can remember). Couldn't get any 100mm solid bar from around my area so had to order it in. The steel supply mob has now moved to Sydney (which is about 100km from where they used to be) from about 10 km from me, so 100mm solid arrived late Friday afternoon. So completed repairs to playground equipment on Friday afternoon and started on this boom bracket on Saturday morning. A good day no interuptions, just good play time. With the materials, right tools and equipment at hand the job does go quite easy

I would bore the 2mm then go right in with the 5mm after using a spot drill (or centre drill) to make sure the 5mm is on point.

I tried that on a previous project, drilling a 5mm hole for the key & drilling a 20mm hole for the shaft. The keyway hole caused the large hole to wander off centre!

I didn't have a lathe at the time but I should have bored the large hole instead.

I tried that on a previous project, drilling a 5mm hole for the key & drilling a 20mm hole for the shaft. The keyway hole caused the large hole to wander off centre!

I didn't have a lathe at the time but I should have bored the large hole instead.

If doing it again could you first drill a center hole in a sacrificial base plate, and then use this with a pilot drill to center align and keep aligned the hole saw?

If doing it again could you first drill a center hole in a sacrificial base plate, and then use this with a pilot drill to center align and keep aligned the hole saw?

I was using a 20mm drill bit, not a hole saw!

I was using a 20mm drill bit, not a hole saw!

Can you not get broaching cutters with pilot drills... I don't know; just wondering.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I can imagine that happening with a big drill unless you had a very rigid pillar drill and clamped the work down tight.I tried that on a previous project, drilling a 5mm hole for the key & drilling a 20mm hole for the shaft. The keyway hole caused the large hole to wander off centre!

I didn't have a lathe at the time but I should have bored the large hole instead.

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

All good stuff.

I'll give it a go later and report back on how I get on.

I don't mind trashing a few bits and have a decent pillar drill and a lathe so no excuse.

I think the similar sizes of holes required will cause the problems.

I'll give it a go later and report back on how I get on.

I don't mind trashing a few bits and have a decent pillar drill and a lathe so no excuse.

I think the similar sizes of holes required will cause the problems.

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

In the good old days when I just had very basic tools I would bore a hole the size of the key at the correct position and then bore out the centre hole afterwards thus leaving a half round keyway that could then be filed out square.

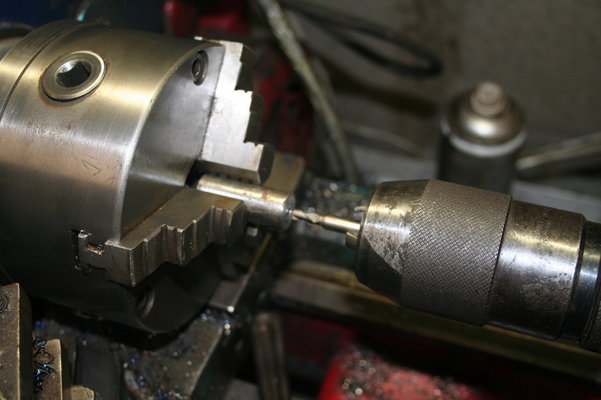

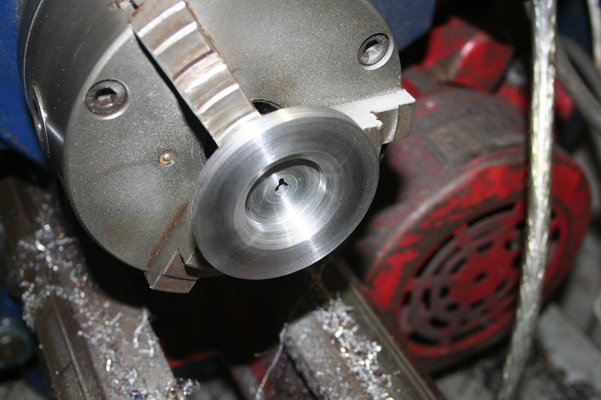

View attachment 188892 View attachment 188893

Today I followed @Hood advice and made a better key-way for the next hand-wheel.

I decided to make this hand wheel in a different way to cut down on the amount of machining so started with a bit of 14mm round bar and drilled it out with a 2mm off set hole and a 5mm central hole using a spot drill and a milling cutter.

I then used a thinner slice of 72mm bar and drilled a 14mm hole in it and welded the pre-drilled 14mm bar into it.

Using this approach meant I didn't need to machine down a shank on the back of the hand wheel and as my wee Boxford can only take tiny cuts, the reduction in machining really shortened the time it took to make this one.

Screwdriver

Forum Supporter

- Messages

- 10,955

Added these magnetic tool holders to a spare bit of OSB I fitted to my parents garage. Helps to keep a few bits and pieces easier to access rather than all crammed in a cabinet.

The only problem with magnets is they pick up swarf, sharps and blades like, well, like a magnet.

As will all of the tools.

The only problem with magnets is they pick up swarf, sharps and blades like, well, like a magnet.

As will all of the tools.

It'll do until I can build new storage, although I try to keep any swarf making activities out of the garage, can't always avoid it, but where I can, I prefer the car in the garage then I'll grind on the drive.

Screwdriver

Forum Supporter

- Messages

- 10,955

I prefer the car in the garage then I'll grind on the drive.

That's too much information thanks.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

In between real work I managed to get the frame for the tall gate welded up.

I then welded the plasma cut design to it, here it is along side the smaller gate.

I still have to weld on the hinge brackets for both gates and then make up the side section for the big gate. Once that is done I can take them to the blaster to see whether they think it will be easy enough to blast them as I would like, if not I will get them to powder coat.

.

I then welded the plasma cut design to it, here it is along side the smaller gate.

I still have to weld on the hinge brackets for both gates and then make up the side section for the big gate. Once that is done I can take them to the blaster to see whether they think it will be easy enough to blast them as I would like, if not I will get them to powder coat.

.