I'll join in  I've only a small workshop and it has to contend with both wood and metal so only small stuff here.

I've only a small workshop and it has to contend with both wood and metal so only small stuff here.

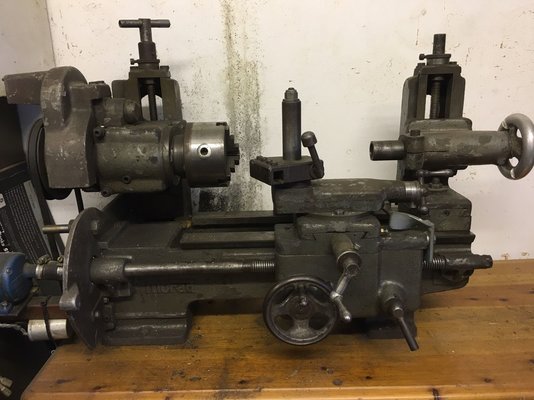

Small Perris lathe, my first, I don't use this any more because it doesn't run very well

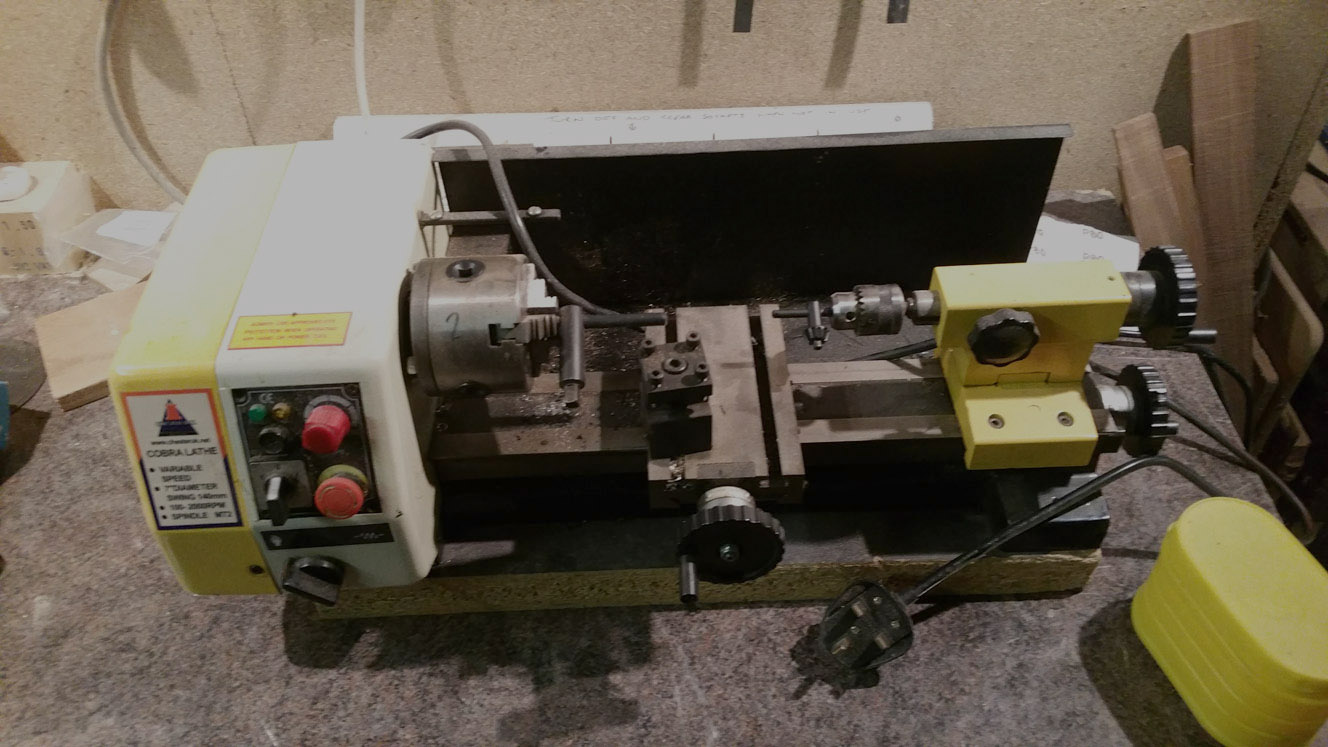

I then got this little Chester Cobra, same as a Sieg C1 Micro. Runs quite nicely but not very featuresome. Currently shelved.

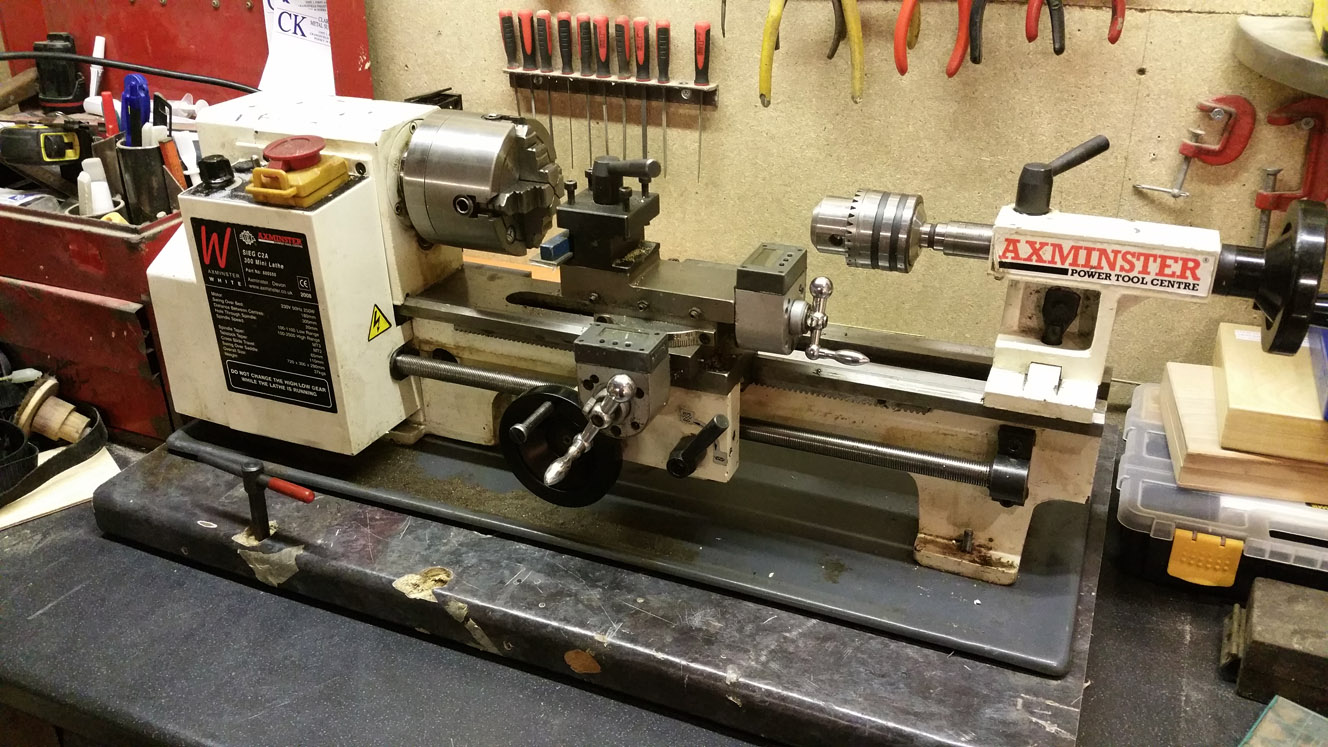

The above was replaced with this, Sieg C2A which is my current model and should do everything I need at the moment. I wish I had space for a larger floor standing model, but not yet.

And for fun, first ever spinning device, which is my Record wood lathe. Ancient photo of when I'd just finished the stand.

Thanks

I've only a small workshop and it has to contend with both wood and metal so only small stuff here.

I've only a small workshop and it has to contend with both wood and metal so only small stuff here.Small Perris lathe, my first, I don't use this any more because it doesn't run very well

I then got this little Chester Cobra, same as a Sieg C1 Micro. Runs quite nicely but not very featuresome. Currently shelved.

The above was replaced with this, Sieg C2A which is my current model and should do everything I need at the moment. I wish I had space for a larger floor standing model, but not yet.

And for fun, first ever spinning device, which is my Record wood lathe. Ancient photo of when I'd just finished the stand.

Thanks

.

.