Following a comment by wedg1e in mattf's lathe wick oilers post, I thought a show us your lathe thread was a great idea.

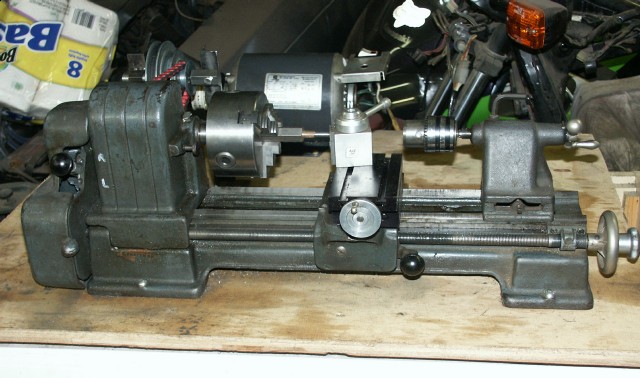

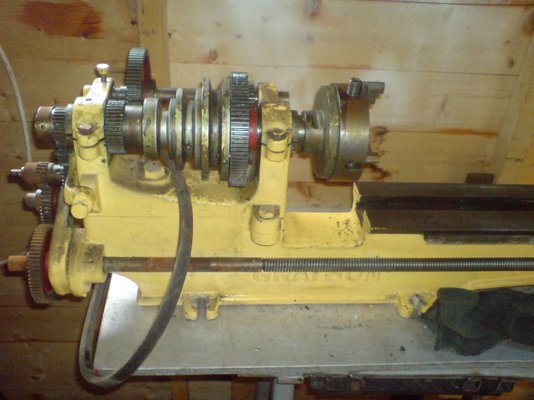

So heres mine, an old 3.5" vintage grayson bought in a moment of madness when I was in "I need a new toy mode" you know how it is I am still in the process of setting it up and working out how to sort out a drive train. I have no idea how to use it or what I am going to do with it

I am still in the process of setting it up and working out how to sort out a drive train. I have no idea how to use it or what I am going to do with it  but it seemed like a good idea at the time

but it seemed like a good idea at the time  and I am sure I am in the right place for some good advice

and I am sure I am in the right place for some good advice

Norm

So heres mine, an old 3.5" vintage grayson bought in a moment of madness when I was in "I need a new toy mode" you know how it is

I am still in the process of setting it up and working out how to sort out a drive train. I have no idea how to use it or what I am going to do with it

I am still in the process of setting it up and working out how to sort out a drive train. I have no idea how to use it or what I am going to do with it  but it seemed like a good idea at the time

but it seemed like a good idea at the time  and I am sure I am in the right place for some good advice

and I am sure I am in the right place for some good adviceNorm