Anybody got any links to an affordable gas thru dinze connector to connect a CK 3/8 BSP to this machine ?

I went for these:

DINSE 35/50 to 3/8 adaptor this is to 3/8" on the machine for the gas so cut that off and put:

M10x1 nut + hose tail

Mini Jubilee clip

The hose tail is 4 - 5mm but someone said earlier in the thread it's fine if you well and truly tighten the jubilee clip. My adaptor hasn't come yet by Royal Snail but I'll confirm if it's fine once I have it...

In the meantime waiting for the adaptor for my CK torch, I did my first welds! Can't wait to use the CK though, it's so much more comfortable to hold.

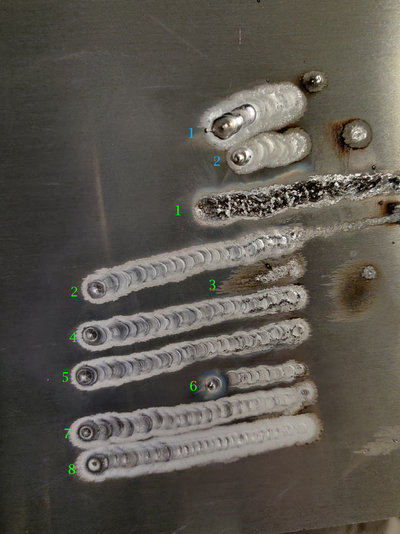

Started with just moving the torch (green numbers). I think gas was still coming through the tubes or something for the first? pre gas was only 0.1 s too, so I upped that to 0.5 s, then I started trying to add filler (blue numbers), but the position was a bit awkward so I started a new column of welds and it went much better!

.

.

! I'll give 85 Hz a go tonight and see how I get on

! I'll give 85 Hz a go tonight and see how I get on

)

) , but either way that's not an issue with the wedge ones)...

, but either way that's not an issue with the wedge ones)... ).

).