slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

Extremely nice looking machine. Look forward to posts about the restoration.

What Carl said, x 2. It must feel a little like Christmas has come early for you this year!

Extremely nice looking machine. Look forward to posts about the restoration.

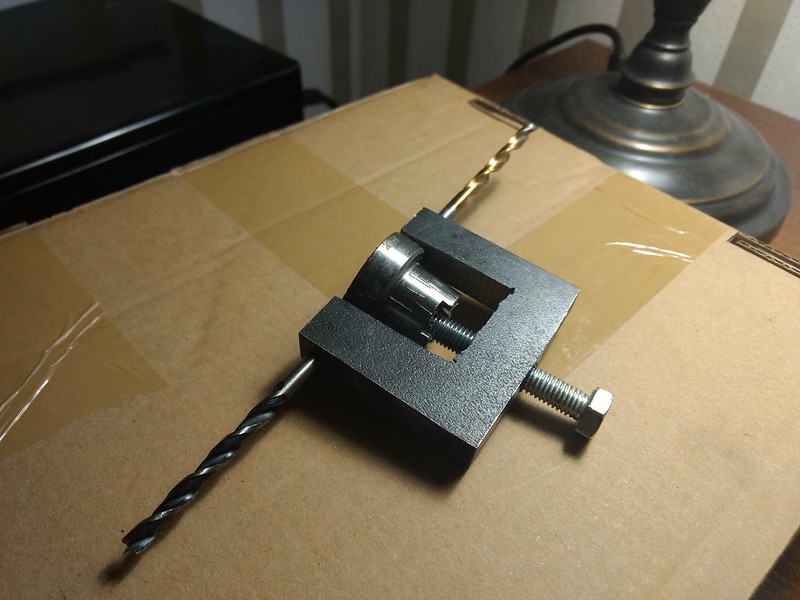

They are face mills that take indexable lathe style tools. Seems they have been welded in place, possibly the clamping screws are rounded or damaged in some other way or possibly they were just never that secure without being welded.Could some of the round cutters be fly cutters?

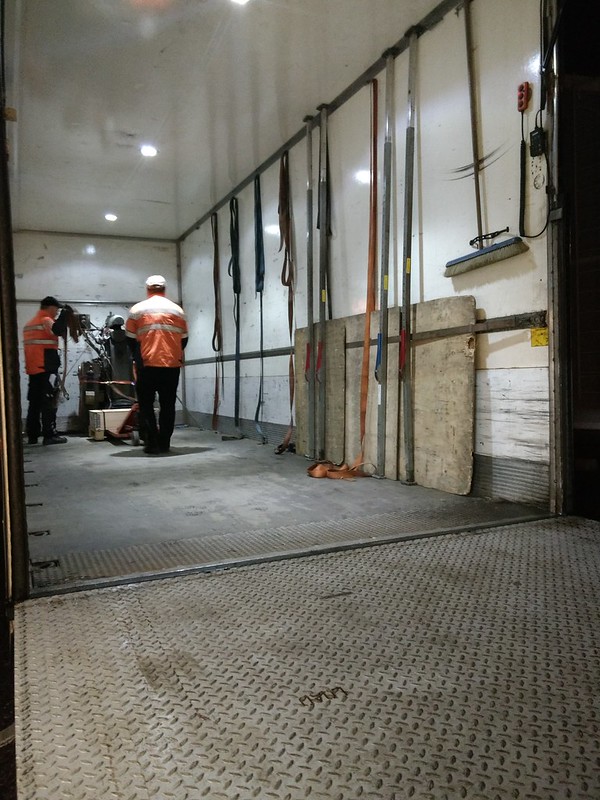

Also for fizzy, here's the tail lift:

It actually went pretty smoothly and the machine was very stable fortunately.

This thread is about recommendations for hobby mills. So I think I will make a dedicated thread for the deckel and move the relevant posts there and let this sink into the archives. Maybe it will help somebody in the future.