DennisCA

Member

- Messages

- 2,017

- Location

- Finland

OK I am making a dedicated thread in the interests of keeping things clear and separated.

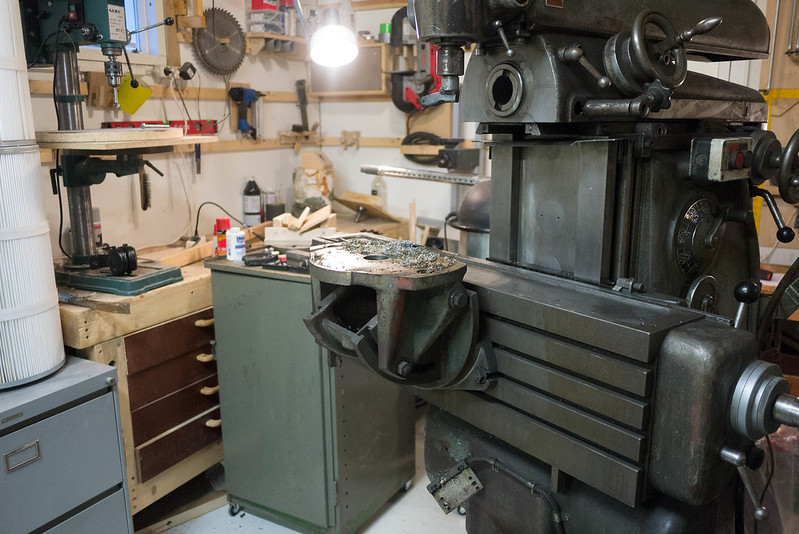

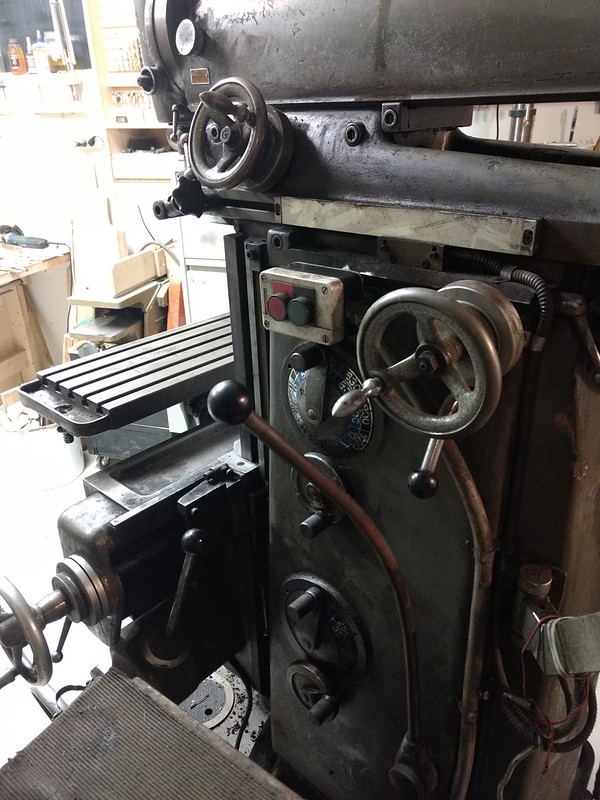

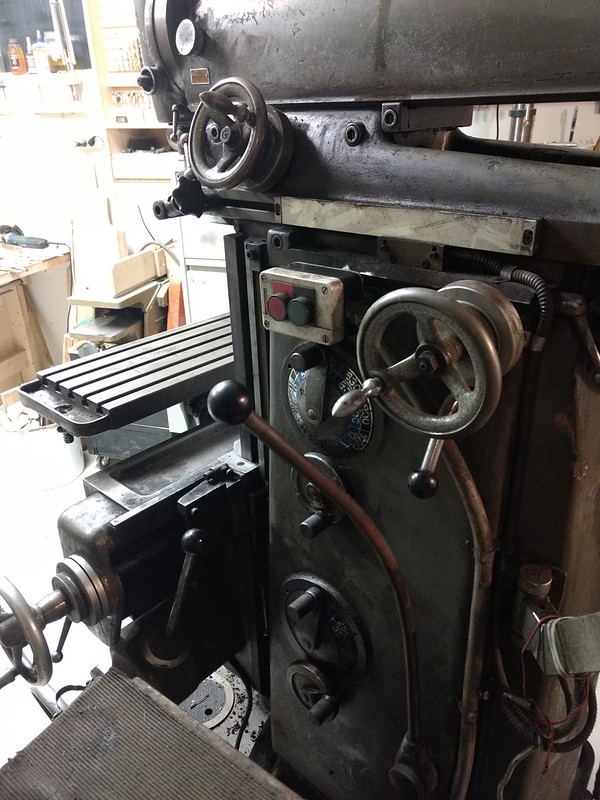

This is the mill when I got it home:

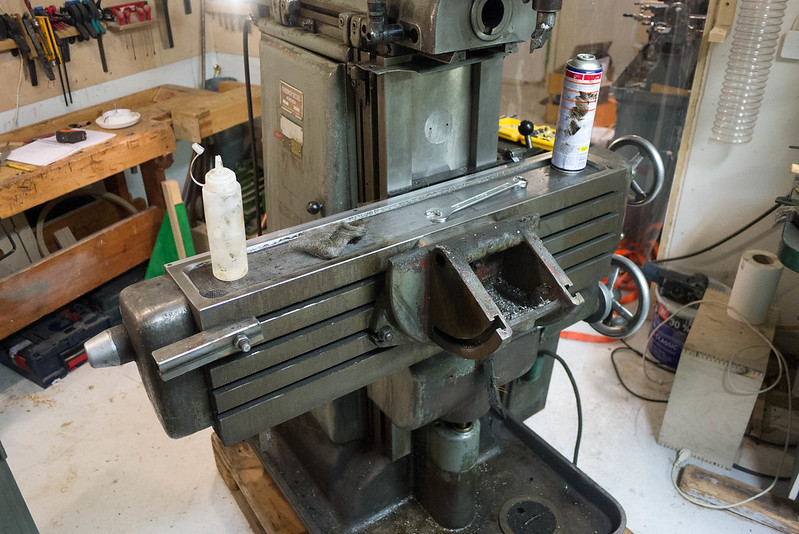

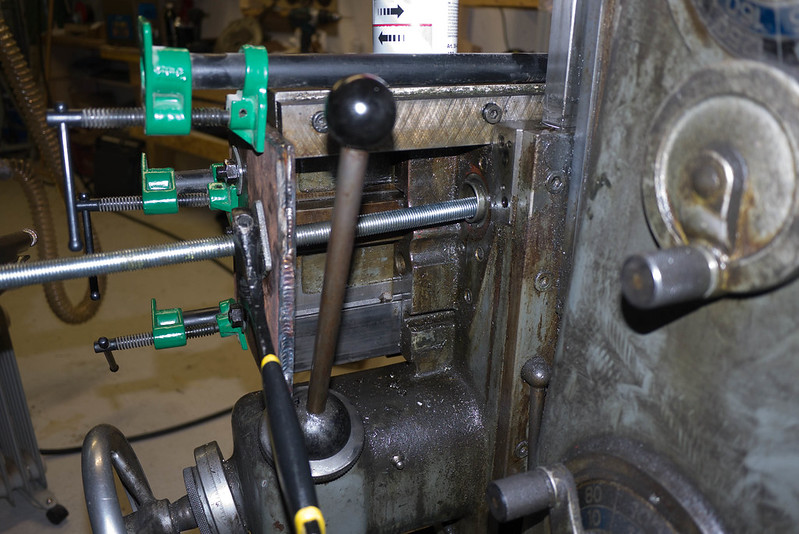

I noticed pretty much straight away that the X-axis is still stuck, the problem is that the tapered gib is really, really stuck, the gib screw looked like this:

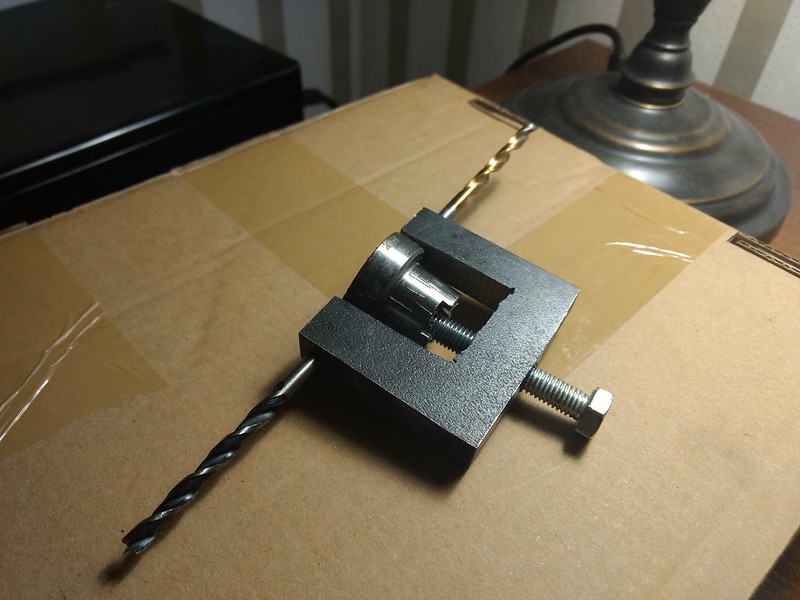

The bit on the tapered gib that retains the screw has sheared off, the screw is bent and the gib has gotten stuck.

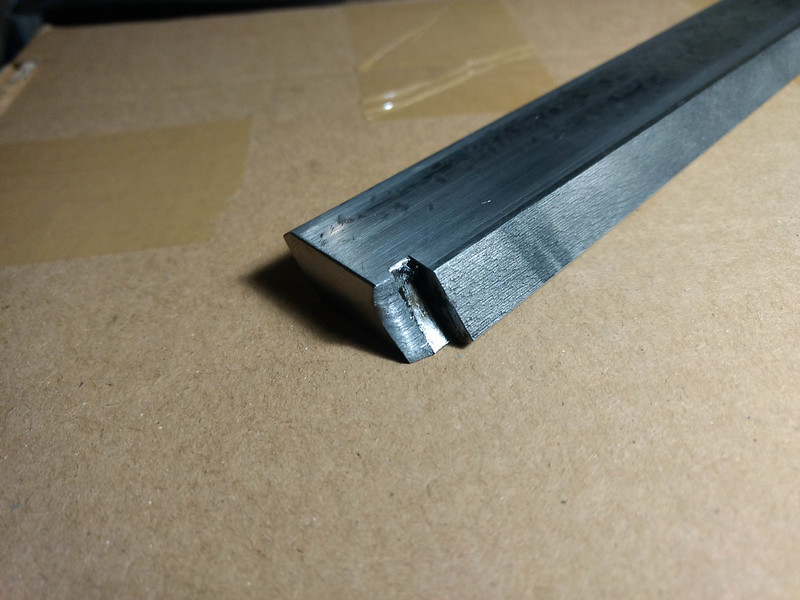

And a closer look at the scale head... Don't think a repair is possible of this.

This is the mill when I got it home:

I noticed pretty much straight away that the X-axis is still stuck, the problem is that the tapered gib is really, really stuck, the gib screw looked like this:

The bit on the tapered gib that retains the screw has sheared off, the screw is bent and the gib has gotten stuck.

And a closer look at the scale head... Don't think a repair is possible of this.