Maker

Most folk just call me; Orange Joe

- Messages

- 10,616

- Location

- Keeler crater

Anyone remember a few years ago I was after some dye to make the oil level in my lathe headstock more visible? For some reason I never did the obvious thing and take the drain plug out to check, until now.

I don't know how long it's been empty but I've never noticed it leaking and I've had it about 4 years and I've never spotted a leak. Luckily 99.9% of the time it's in high speed mode and the gears aren't engaged so the only damage is the "clutch lever shifter pads", No.65 in the drawing.

Luckily 99.9% of the time it's in high speed mode and the gears aren't engaged so the only damage is the "clutch lever shifter pads", No.65 in the drawing.

The rest of them was sat in a pile underneath.

I'll clean it out as best I can before I refill it. I thought the worn blocks would just give the clutch lever a bit of play which has never bothered me but it looks like it could be preventing the spindle brake from engaging properly, it does take a few seconds longer to slow down than I think it used to. Easy enough to make new ones (With a working lathe ).

).

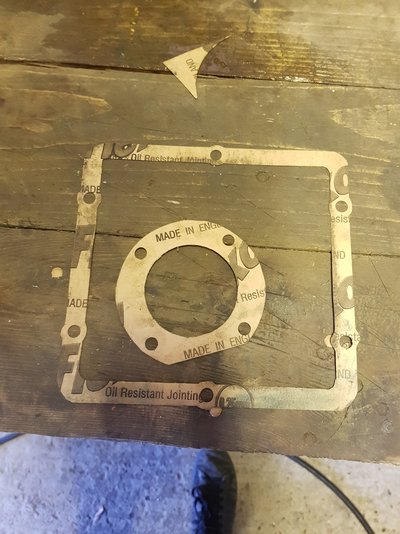

It looks like there's some liquid gasket stuff on the cover too, I'll scrape that off and replace it before it goes back together.

I don't know how long it's been empty but I've never noticed it leaking and I've had it about 4 years and I've never spotted a leak.

Luckily 99.9% of the time it's in high speed mode and the gears aren't engaged so the only damage is the "clutch lever shifter pads", No.65 in the drawing.

Luckily 99.9% of the time it's in high speed mode and the gears aren't engaged so the only damage is the "clutch lever shifter pads", No.65 in the drawing.

The rest of them was sat in a pile underneath.

I'll clean it out as best I can before I refill it. I thought the worn blocks would just give the clutch lever a bit of play which has never bothered me but it looks like it could be preventing the spindle brake from engaging properly, it does take a few seconds longer to slow down than I think it used to. Easy enough to make new ones (With a working lathe

).

).It looks like there's some liquid gasket stuff on the cover too, I'll scrape that off and replace it before it goes back together.

I'll have a look for some O rings, there's a 11 listed in the parts for the headstock, should be numbers 116, 126, 143 and 144 in the diagram in the first post but none of those numbers are in the drawing.

I'll have a look for some O rings, there's a 11 listed in the parts for the headstock, should be numbers 116, 126, 143 and 144 in the diagram in the first post but none of those numbers are in the drawing.

It appears to be a standard size, BS012.

It appears to be a standard size, BS012.