You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Boat project, it will be worth it ;)

- Thread starter W.olly

- Start date

Jlg

Member

- Messages

- 2,586

- Location

- Cumbria

Give it a good check they have a habit of getting fishing line wrapped around and that destroyes the sealsYes a 4 stroke it is, i trust the chap i got it off but will check it all over. It is only until i get a newer one maybe.

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

Its been a naff week or so here on and off the boat. Myself had serious toothache and had it ripped out and still suffering a week after. Off a few days last week with it and as it was nice annoyed me as i couldnt concentrate to do work on the boat. Feel a bit better today and back to work this morning

What has been done over the last few weeks, well got the engine fitted and working, but i bought remote to short by a foot so waste of £40 , what a plonker, the steering cable is good as i had to soak it in air tool oil to loosen it up. well fine again.

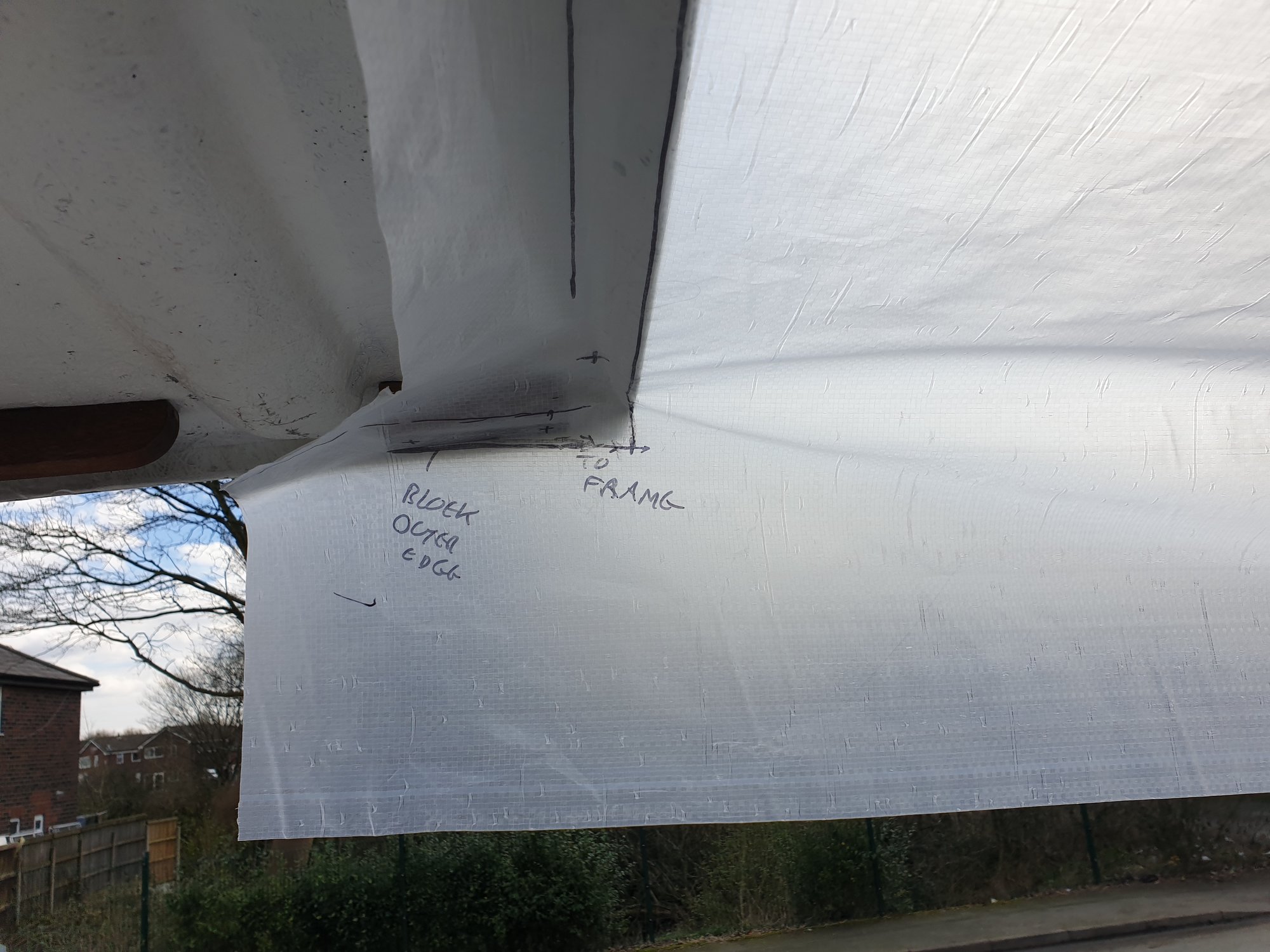

when i could was a cock up with the canopy patterns. I first used thick 800grm polythene sheet for the pattern material, as seen on the trailer, for that a it was ok but on the boat, not so good as to stiff so i got some 350grm, good thickness but it stretches to much easily.

image: https://i.postimg.cc/Bs29bts5/20190221-130806.jpg

So i have ordered some proper pattern material, Fibretex and all the Lift The Dot fittings. Well think i have . Also some more basting tape as near ran out faffing with it. What else, oh yes and i think i will be getting more zips to remove all the sides so then i can have just the top section inplace if we want.

Still on the canopy i mentioned that the rear section i wanted to be fixed to a vertical surface, and if you look back it was at around 45 deg. Now it is 90 deg after i laminated inplace the sections i made a few week back.

image: https://i.postimg.cc/cHXfKS05/20190223-151209.jpg

Filled the ends with a filler i made from chopped up CSM and poly resin. Just mix the resin as normal and then add the CSM cuttings and mix in, it will show how fast the binder breaks down.

image: https://i.postimg.cc/x8j8zJtK/20190223-151105.jpg

image: https://i.postimg.cc/gjBzLMwW/20190223-154343.jpg

So just slap it in the hole let set then sand back. In above pic you can see i filled it with expanding foam to get a back to fill to.

image: https://i.postimg.cc/RFMgGKCq/20190224-153046.jpg

image: https://i.postimg.cc/bw7M0Z22/20190224-153054.jpg

Now for now that is that untill the Fibretex arrives, tomorrow i hope form what they charge for postage., dam shocking.

One job i just could not decide on was what to do with he hatch opening. This weekend i decided to just try this idea instead of trimming it with hardwood.

One thing i did wrong is forget to wet the inside of the tunnels that i made from polythene and masking tape to help it set, not easy though if i did to get water to stay on polythene. But it worked out just about as in the end i cut a few slashes in the polythene to let air get in.

I need to trim it more as just did it tonight when i got home to see if it had all set. few large air pockets but no problem, this is with filling to much and not dampening the `mould`

image: https://i.postimg.cc/mkP1t1dt/20190224-130949.jpg

Filled with expanding foam.

not to much as you can see i got carried away.

image: https://i.postimg.cc/0NQgZzkk/20190224-132329.jpg

image: https://i.postimg.cc/C1B3T9n9/20190224-133355.jpg

Trimmed back a little, need to do a lot more as the hatch bolt need access points and then laminating up.

image: https://i.postimg.cc/zJ7Lt6j3/20190225-172925.jpg

So plan is to get the canopy made and get the boat sanded and painted is the priority along with fitting the linings and upholstery.

If all that is done with a few other little bits like outboard mount and this and that it will be launched May 18th..............dont hold your breath.

I was a little peeed off a few week back as i tried a new supplier for some pattern material and fittings which took six days to get here and still waitng for a few parts to arrive after paying over the norm for delivery. I will not be using Snuggtopz again as they are complete useless and unprofessional.

So in the mean time i have got on with the internal vanishing and lining out. I used a hi temp spray adhesive as we dont want it falling off or coming loose on the real hot summer we get a lot of in the UK......a little sarcy there lol.

I did mess up a little on the varnishing as the front panel where the sockets are i ended up with a few runs. I used a foam roller and flatted out with foam brush. I think i was just rushing, No big deal a quick sand otu of the runs and another quick coat will do the job. All the rest is good

Looking better now .

.

All was varnished with Len Tonkinois. Solid wood three coats and veneered was two coats.

image: https://i.postimg.cc/qM4qTC1T/20190309-152058.jpg

image: https://i.postimg.cc/gksJkk76/20190309-152055.jpg

Used this adhesive

image: https://i.postimg.cc/7hYLSFGL/20190310-145538.jpg

image: https://i.postimg.cc/vTqZh0ft/20190310-145517.jpg

image: https://i.postimg.cc/7ZTZ1M6S/20190310-172441.jpg

image: https://i.postimg.cc/0N0xZtqK/20190310-172517.jpg

image: https://i.postimg.cc/xCjQZK0x/20190310-172545.jpg

image: https://i.postimg.cc/NjTQ2sJ4/20190310-172956.jpg

Next up is to finish the hatch surround and then i can line the front panel and under the front deck. Still more to varnish on the cupboard door frame sas they are solid Sapele so need three coats at least.

I just want a good few days to crack on with this canopy. I got Fibretex pattern material as the sheet i was using was either to tin and stretched or to thick.

Captain Faffer

What has been done over the last few weeks, well got the engine fitted and working, but i bought remote to short by a foot so waste of £40 , what a plonker, the steering cable is good as i had to soak it in air tool oil to loosen it up. well fine again.

when i could was a cock up with the canopy patterns. I first used thick 800grm polythene sheet for the pattern material, as seen on the trailer, for that a it was ok but on the boat, not so good as to stiff so i got some 350grm, good thickness but it stretches to much easily.

image: https://i.postimg.cc/Bs29bts5/20190221-130806.jpg

So i have ordered some proper pattern material, Fibretex and all the Lift The Dot fittings. Well think i have . Also some more basting tape as near ran out faffing with it. What else, oh yes and i think i will be getting more zips to remove all the sides so then i can have just the top section inplace if we want.

Still on the canopy i mentioned that the rear section i wanted to be fixed to a vertical surface, and if you look back it was at around 45 deg. Now it is 90 deg after i laminated inplace the sections i made a few week back.

image: https://i.postimg.cc/cHXfKS05/20190223-151209.jpg

Filled the ends with a filler i made from chopped up CSM and poly resin. Just mix the resin as normal and then add the CSM cuttings and mix in, it will show how fast the binder breaks down.

image: https://i.postimg.cc/x8j8zJtK/20190223-151105.jpg

image: https://i.postimg.cc/gjBzLMwW/20190223-154343.jpg

So just slap it in the hole let set then sand back. In above pic you can see i filled it with expanding foam to get a back to fill to.

image: https://i.postimg.cc/RFMgGKCq/20190224-153046.jpg

image: https://i.postimg.cc/bw7M0Z22/20190224-153054.jpg

Now for now that is that untill the Fibretex arrives, tomorrow i hope form what they charge for postage., dam shocking.

One job i just could not decide on was what to do with he hatch opening. This weekend i decided to just try this idea instead of trimming it with hardwood.

One thing i did wrong is forget to wet the inside of the tunnels that i made from polythene and masking tape to help it set, not easy though if i did to get water to stay on polythene. But it worked out just about as in the end i cut a few slashes in the polythene to let air get in.

I need to trim it more as just did it tonight when i got home to see if it had all set. few large air pockets but no problem, this is with filling to much and not dampening the `mould`

image: https://i.postimg.cc/mkP1t1dt/20190224-130949.jpg

Filled with expanding foam.

not to much as you can see i got carried away.

image: https://i.postimg.cc/0NQgZzkk/20190224-132329.jpg

image: https://i.postimg.cc/C1B3T9n9/20190224-133355.jpg

Trimmed back a little, need to do a lot more as the hatch bolt need access points and then laminating up.

image: https://i.postimg.cc/zJ7Lt6j3/20190225-172925.jpg

So plan is to get the canopy made and get the boat sanded and painted is the priority along with fitting the linings and upholstery.

If all that is done with a few other little bits like outboard mount and this and that it will be launched May 18th..............dont hold your breath.

I was a little peeed off a few week back as i tried a new supplier for some pattern material and fittings which took six days to get here and still waitng for a few parts to arrive after paying over the norm for delivery. I will not be using Snuggtopz again as they are complete useless and unprofessional.

So in the mean time i have got on with the internal vanishing and lining out. I used a hi temp spray adhesive as we dont want it falling off or coming loose on the real hot summer we get a lot of in the UK......a little sarcy there lol.

I did mess up a little on the varnishing as the front panel where the sockets are i ended up with a few runs. I used a foam roller and flatted out with foam brush. I think i was just rushing, No big deal a quick sand otu of the runs and another quick coat will do the job. All the rest is good

Looking better now

.

. All was varnished with Len Tonkinois. Solid wood three coats and veneered was two coats.

image: https://i.postimg.cc/qM4qTC1T/20190309-152058.jpg

image: https://i.postimg.cc/gksJkk76/20190309-152055.jpg

Used this adhesive

image: https://i.postimg.cc/7hYLSFGL/20190310-145538.jpg

image: https://i.postimg.cc/vTqZh0ft/20190310-145517.jpg

image: https://i.postimg.cc/7ZTZ1M6S/20190310-172441.jpg

image: https://i.postimg.cc/0N0xZtqK/20190310-172517.jpg

image: https://i.postimg.cc/xCjQZK0x/20190310-172545.jpg

image: https://i.postimg.cc/NjTQ2sJ4/20190310-172956.jpg

Next up is to finish the hatch surround and then i can line the front panel and under the front deck. Still more to varnish on the cupboard door frame sas they are solid Sapele so need three coats at least.

I just want a good few days to crack on with this canopy. I got Fibretex pattern material as the sheet i was using was either to tin and stretched or to thick.

Captain Faffer

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

I was off work a while ago as i had to go to the hospital so as it was a nice day for once i grabbed the chance to start the canopy patterns. What pain in the **** that was, just the two rear hardtop corners to get a nice curve to the canvas.

The Material i got for the patterns is spot on ( Fibretex ) flexible and no stretch at all.

This is the corners that proved difficult o get it how i wanted. All sorted now though.

image: https://i.postimg.cc/yN38h78H/20190320-114414.jpg

image: https://i.postimg.cc/HndWC54Y/20190320-114418.jpg

image: https://i.postimg.cc/qv57CN0w/20190320-114411.jpg

So then it was mark it all up time for the top section.

image: https://i.postimg.cc/bJXN34Z2/20190320-134512.jpg

Then i made a full rear section although this will done in smaller sections. So the top trim to go all around the top section dropping down by 6 inch. Rear section will have a rear window which can be rolled up or removed all together leaving corner upstands about 6 inch down the sides and rear. to leave all open i we want.

image: https://i.postimg.cc/cHN0QYzR/20190320-155948.jpg

image: https://i.postimg.cc/LsPmYvx4/20190320-152628.jpg

I have gone with Lift the Dot fittings all around and the rest will be Zips fro material to material for detachable sides and rear.

I lowered a bit more the hoop to hope to get a better run off. If not i have aspring loaded bar that can slot in the canopy top when not on board to give a more support.

Looking again at these pics it doesnt look to taught but its better than the pics, i cant remember if i took these be for i give it fettle more.

Saying that if it works i will be amazed lol

The Material i got for the patterns is spot on ( Fibretex ) flexible and no stretch at all.

This is the corners that proved difficult o get it how i wanted. All sorted now though.

image: https://i.postimg.cc/yN38h78H/20190320-114414.jpg

image: https://i.postimg.cc/HndWC54Y/20190320-114418.jpg

image: https://i.postimg.cc/qv57CN0w/20190320-114411.jpg

So then it was mark it all up time for the top section.

image: https://i.postimg.cc/bJXN34Z2/20190320-134512.jpg

Then i made a full rear section although this will done in smaller sections. So the top trim to go all around the top section dropping down by 6 inch. Rear section will have a rear window which can be rolled up or removed all together leaving corner upstands about 6 inch down the sides and rear. to leave all open i we want.

image: https://i.postimg.cc/cHN0QYzR/20190320-155948.jpg

image: https://i.postimg.cc/LsPmYvx4/20190320-152628.jpg

I have gone with Lift the Dot fittings all around and the rest will be Zips fro material to material for detachable sides and rear.

I lowered a bit more the hoop to hope to get a better run off. If not i have aspring loaded bar that can slot in the canopy top when not on board to give a more support.

Looking again at these pics it doesnt look to taught but its better than the pics, i cant remember if i took these be for i give it fettle more.

Saying that if it works i will be amazed lol

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

So plan is in the next few weeks i am going to get done the BSS work and get it in when i am off in May. There is little to do and i got the worst or biggest job done now. That was the locker seat tops. If you remember it was made from the same ply as the deck was originally used and crap ply from Wicks, which should of been hardwood WBP but it just delaminated a the rear deck did..

I made them from 7-8mm thick GRP sheet that i made.

Alll sorted now

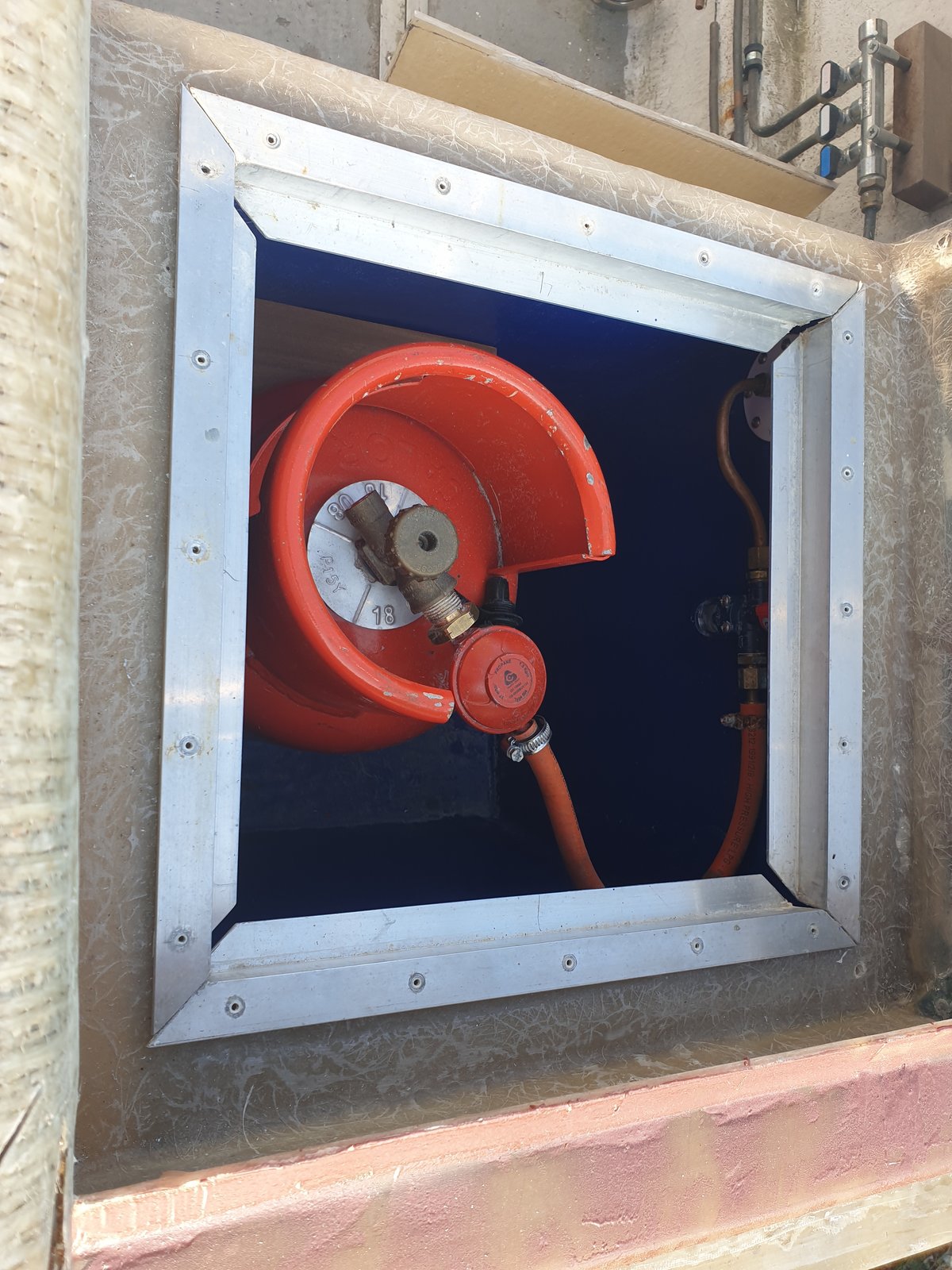

Now other things were to slide flex pipe over the gas pipe thats goes under the rear deck as the batteries are below that and if forgot to do that when i done the gas work. Thats done anyway. Then a few vents around where the charger is.

Made a gas cylinder bracket/steady.

Just to seal where pipe work and cables goes through the lower bulkhead.

So where am i now.

Before Op ( 30th April ) BSS work to be done, then when i am off sick i will do what i can with the one arm i have use of, sanding the top deck if i can etc hull work is still to be done. biggest job.. I will be making the canopy after a few weeks resting and had the cast off. Then in hope the canopy is done then first three weeks in June will be sanding and painting the boat. I have bought the fenders, ropes,, new bilge pump to fit when launched as i dont know the low point in the bilge.

Oh how can i forget i have got a good price for the cushions which i really want to be done as when launched i want it to be cosy for the first few days cruising.

I an going to book the crane in for the 24th June for my birthday well day after. We have the week off to cruise around for a bit.

So it all go from now on with this and work.

I made them from 7-8mm thick GRP sheet that i made.

Alll sorted now

Now other things were to slide flex pipe over the gas pipe thats goes under the rear deck as the batteries are below that and if forgot to do that when i done the gas work. Thats done anyway. Then a few vents around where the charger is.

Made a gas cylinder bracket/steady.

Just to seal where pipe work and cables goes through the lower bulkhead.

So where am i now.

Before Op ( 30th April ) BSS work to be done, then when i am off sick i will do what i can with the one arm i have use of, sanding the top deck if i can etc hull work is still to be done. biggest job.. I will be making the canopy after a few weeks resting and had the cast off. Then in hope the canopy is done then first three weeks in June will be sanding and painting the boat. I have bought the fenders, ropes,, new bilge pump to fit when launched as i dont know the low point in the bilge.

Oh how can i forget i have got a good price for the cushions which i really want to be done as when launched i want it to be cosy for the first few days cruising.

I an going to book the crane in for the 24th June for my birthday well day after. We have the week off to cruise around for a bit.

So it all go from now on with this and work.

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

I have been busy with this and that. Things have changed but not much as the all important launching is still on the 24th June but BSS is now 18th May. Only as my operation was cancelled for yesterday and is now not till 11th June, so two weeks before launch.

I am doing what i can filling and sanding and about to order the paint tomorrow. All BSS work is done but for the charger vent as i cant find the dam 35mm hole saw for the vents. I double checked all LPG work well appliances so hot water and heating all good with cooker. BUT for a very slight leak on the water heater, i cant fathom it at the minute as there are only two fittings from cut off to boiler. I checked it again last night and it seems o have stopped though. Going to go through ti again this weekend as that is important really lol..

Oh and i decide to make a transom saver so will post that when i have finished it.

I am trying to decide if to fit the two strakes not needed but mite finish the bot of nice to match the top one i have finished varnishing.

.jpg.2b90c3b1ccf85ccd8336a8249381e431.jpg)

I am doing what i can filling and sanding and about to order the paint tomorrow. All BSS work is done but for the charger vent as i cant find the dam 35mm hole saw for the vents. I double checked all LPG work well appliances so hot water and heating all good with cooker. BUT for a very slight leak on the water heater, i cant fathom it at the minute as there are only two fittings from cut off to boiler. I checked it again last night and it seems o have stopped though. Going to go through ti again this weekend as that is important really lol..

Oh and i decide to make a transom saver so will post that when i have finished it.

I am trying to decide if to fit the two strakes not needed but mite finish the bot of nice to match the top one i have finished varnishing.

.jpg.2b90c3b1ccf85ccd8336a8249381e431.jpg)

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

Here is one job i have done a week or so ago. For some daft reason i set the wiring in place for the horn to be in front of the Helm position. I could of got a smaller horn but why do that even though this one is big and gets in the way of seeing where your going.

So easy enough, ( good job i left the tails long enough ) just cut a slit to feed the cable to the middle so the horn has a better position.

To the left

Much better central

So as said easy to do.

Get the gear out a si made my own bride filler with chopped CSM mixed into prepped poly resin

Fill it in, lest see if you notice one thing i forgot to do due to rushing it being with being mithered again

I gave it a single lamination of the 300grm CSM

Fettled to make good

So easy enough, ( good job i left the tails long enough ) just cut a slit to feed the cable to the middle so the horn has a better position.

To the left

Much better central

So as said easy to do.

Get the gear out a si made my own bride filler with chopped CSM mixed into prepped poly resin

Fill it in, lest see if you notice one thing i forgot to do due to rushing it being with being mithered again

I gave it a single lamination of the 300grm CSM

Fettled to make good

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

So as said i made a transom saver. Many like them some dont. After owning a lot of GRP boats i thought while i am at it i will make one.

It is made from 2mm stainless steel plate. Bent in a vice with a few bits of timber.

The outboard will be bolted through it and the transom.

To help it bend it cut a mm through it

So for the bolt holes through the transom its just the matter to drill over size to 16mm for the M10 bolt then fill with epoxy filler and drill though again.

It is made from 2mm stainless steel plate. Bent in a vice with a few bits of timber.

The outboard will be bolted through it and the transom.

To help it bend it cut a mm through it

So for the bolt holes through the transom its just the matter to drill over size to 16mm for the M10 bolt then fill with epoxy filler and drill though again.

brightspark

Member

- Messages

- 41,590

- Location

- yarm stockton on tees

click on each link imgNo pics

Jlg

Member

- Messages

- 2,586

- Location

- Cumbria

Error 101acses deniedclick on each link img

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

I was off work today as i had to go to the hospital so as it was a nice day fro once i grabbed the chance to start the canopy patterns. What pain in the **** that was, just the two rear hardtop corners to get a nice curve to the canvas.

The Material i got for the patterns is spot on ( Fibretex ) flexible and no stretch at all.

This is the corners that proved difficult o get it how i wanted. All sorted now though.

So then it was mark it all up time for the top section.

I have gone with Lift the Dot fittings all around and the rest will be Zips fro material to material for detachable sides and rear.

I lowered a bit more the hoop to hope to get a better run off. If not i have aspring loaded bar that can slot in the canopy top when not on board to give a more support.

Looking again at these pics it doesnt look to taught but its better than the pics, i cant remember if i took these be for i give it fettle more.

Saying that if it works i will be amazed lol

Captain Faffer

The Material i got for the patterns is spot on ( Fibretex ) flexible and no stretch at all.

This is the corners that proved difficult o get it how i wanted. All sorted now though.

So then it was mark it all up time for the top section.

I have gone with Lift the Dot fittings all around and the rest will be Zips fro material to material for detachable sides and rear.

I lowered a bit more the hoop to hope to get a better run off. If not i have aspring loaded bar that can slot in the canopy top when not on board to give a more support.

Looking again at these pics it doesnt look to taught but its better than the pics, i cant remember if i took these be for i give it fettle more.

Saying that if it works i will be amazed lol

Captain Faffer

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

So plan is in the next few weeks i am going to get done the BSS work and get it in when i am off in May. There is little to do and i got the worst or biggest job done now. That was the locker seat tops. If you remember it was made from the same ply as the deck was originally used and crap ply from Wicks, which should of been hardwood WBP but it just delaminated a the rear deck did..

I made them from 7-8mm thick GRP sheet that i made up

.

.

All sorted, last forever now.

Now other things were to slide flexi pipe over the gas pipe thats goes under the rear deck as the batteries are below that and if forgot to do that when i done the gas work. Thats done anyway. Then a few vents around where the charger is.

Made a gas cylinder bracket/steady.

Just to seal where pipe work and cables goes through the lower bulkhead.

So where am i now.

Before Op ( 30th April ) BSS work to be done, then when i am off sick i will do what i can with the one arm i have use of, sanding the top deck if i can etc hull work is still to be done. biggest job.. I will be making the canopy after a few weeks resting and had the cast off. Then in hope the canopy is done then first three weeks in June will be sanding and painting the boat. I have bought the fenders, ropes,, new bilge pump to fit when launched as i dont know the low point in the bilge.

Oh how can i forget i have got a good price for the cushions which i really want to be done as when launched i want it to be cosy for the first few days cruising.

I an going to book the crane in for the 24th June for my birthday well day after. We have the week off to cruise around for a bit.

So it all go from now on with this and work.

I made them from 7-8mm thick GRP sheet that i made up

All sorted, last forever now.

Now other things were to slide flexi pipe over the gas pipe thats goes under the rear deck as the batteries are below that and if forgot to do that when i done the gas work. Thats done anyway. Then a few vents around where the charger is.

Made a gas cylinder bracket/steady.

Just to seal where pipe work and cables goes through the lower bulkhead.

So where am i now.

Before Op ( 30th April ) BSS work to be done, then when i am off sick i will do what i can with the one arm i have use of, sanding the top deck if i can etc hull work is still to be done. biggest job.. I will be making the canopy after a few weeks resting and had the cast off. Then in hope the canopy is done then first three weeks in June will be sanding and painting the boat. I have bought the fenders, ropes,, new bilge pump to fit when launched as i dont know the low point in the bilge.

Oh how can i forget i have got a good price for the cushions which i really want to be done as when launched i want it to be cosy for the first few days cruising.

I an going to book the crane in for the 24th June for my birthday well day after. We have the week off to cruise around for a bit.

So it all go from now on with this and work.

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

have been busy with this and that. Things have changed but not much as the all important launching is still on the 24th June but BSS is now 18th May. Only as my operation was cancelled for yesterday and is now not till 11th June, so two weeks before launch.

I am doing what i can filling and sanding and about to order the paint tomorrow. All BSS work is done but for the charger vent as i cant find the dam 35mm hole saw for the vents. I double checked all LPG work well appliances so hot water and heating all good with cooker. BUT for a very slight leak on the water heater, i cant fathom it at the minute as there are only two fittings from cut off to boiler. I checked it again last night and it seems o have stopped though. Going to go through ti again this weekend as that is important really lol..

Oh and i decide to make a transom saver so will post that when i have finished it.

I am trying to decide if to fit the two strakes not needed but mite finish the bot of nice to match the top one i have finished varnishing.

A good belt sander did wonders here.

I am doing what i can filling and sanding and about to order the paint tomorrow. All BSS work is done but for the charger vent as i cant find the dam 35mm hole saw for the vents. I double checked all LPG work well appliances so hot water and heating all good with cooker. BUT for a very slight leak on the water heater, i cant fathom it at the minute as there are only two fittings from cut off to boiler. I checked it again last night and it seems o have stopped though. Going to go through ti again this weekend as that is important really lol..

Oh and i decide to make a transom saver so will post that when i have finished it.

I am trying to decide if to fit the two strakes not needed but mite finish the bot of nice to match the top one i have finished varnishing.

A good belt sander did wonders here.

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

Here is one job i have done a week or so ago. For some daft reason i set the wiring in place for the horn to be in front of the Helm position. I could of got a smaller horn but why do that even though this one is big and gets in the way of seeing where your going.

So easy enough, ( good job i left the tails long enough ) just cut a slit to feed the cable to the middle so the horn has a better position.

Then fnish with a 300grm CSM top.

So easy enough, ( good job i left the tails long enough ) just cut a slit to feed the cable to the middle so the horn has a better position.

Then fnish with a 300grm CSM top.

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

So as said i made a transom saver. Many like them some dont. After owning a lot of GRP boats i thought while i am at it i will make one.

It is made from 2mm stainless steel plate. Bent in a vice with a few bits of timber.

The outboard will be bolted through it and the transom.

So for the bolt holes through the transom its just the matter to drill over size to 16mm for the M10 bolt then fill with epoxy filler and drill though again.

It is made from 2mm stainless steel plate. Bent in a vice with a few bits of timber.

The outboard will be bolted through it and the transom.

So for the bolt holes through the transom its just the matter to drill over size to 16mm for the M10 bolt then fill with epoxy filler and drill though again.

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

So weekend gone i got it painted with out and dramas but for near killing me lol. I used Jotun paints which i do like. good price and easy to apply and no need to prep for more coats.

The rest underneath will be done bit by bit over the next few weeks as and when i can feel up to it. Got four weeks to get it all done

Have gas leaks now for some odd reason which started with the water heater line then the cooker and now all three lines are leaking, using bubble tester. I am very low indeed on gas so i have been told that could be the problem so to get a refill first to see what happens. Low pressures can cause bubbles in a bubble tester.

image: https://i.postimg.cc/BZ72XnRz/20190512-185415.jpg

image: https://i.postimg.cc/wv0L5qM7/20190512-185336.jpg

image: https://i.postimg.cc/BQ8HDG0n/20190512-185457.jpg

image: https://i.postimg.cc/N0v6BCZf/20190512-185358.jpg

The rest underneath will be done bit by bit over the next few weeks as and when i can feel up to it. Got four weeks to get it all done

Have gas leaks now for some odd reason which started with the water heater line then the cooker and now all three lines are leaking, using bubble tester. I am very low indeed on gas so i have been told that could be the problem so to get a refill first to see what happens. Low pressures can cause bubbles in a bubble tester.

image: https://i.postimg.cc/BZ72XnRz/20190512-185415.jpg

image: https://i.postimg.cc/wv0L5qM7/20190512-185336.jpg

image: https://i.postimg.cc/BQ8HDG0n/20190512-185457.jpg

image: https://i.postimg.cc/N0v6BCZf/20190512-185358.jpg